Content Menu

● Understanding Aluminum Extrusion

>> The Aluminum Extrusion Process

● Identifying the Correct HS Code

>> 1. Determine Product Specifications

>> 2. Consult Official Resources

>> 3. Utilize Online Databases

>> 4. Seek Professional Help

● Importance of Correct HS Code Classification

● Applications of Aluminum Extrusions

>> Building and Construction

>> Automotive Industry

>> Aerospace Applications

>> Industrial Machinery

>> Consumer Goods

● Challenges in Classifying Aluminum Extrusions

● Best Practices for Accurate Classification

● Expanding Further on Aluminum Extrusion Applications

● Detailed Applications of Aluminum Extrusions

>> Architectural Applications

>> Transportation Sector Innovations

>> Electronics Industry Utilization

● Market Trends Influencing Aluminum Extrusion Demand

● Conclusion

● FAQ

>> 1. What is an HS code?

>> 2. Why is it important to use the correct HS code?

>> 3. Where can I find my product's HS code?

>> 4. What are some common HS codes for aluminum extrusions?

>> 5. Can I classify my product under multiple HS codes?

● Citations:

Finding the correct HS code for aluminum extrusion products is crucial for businesses involved in international trade. The Harmonized System (HS) code is an internationally standardized system of names and numbers for classifying traded products. Understanding how to identify the right HS code can help streamline customs processes, avoid delays, and ensure compliance with import/export regulations.

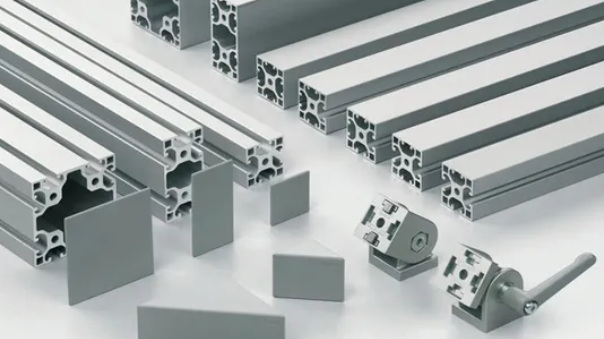

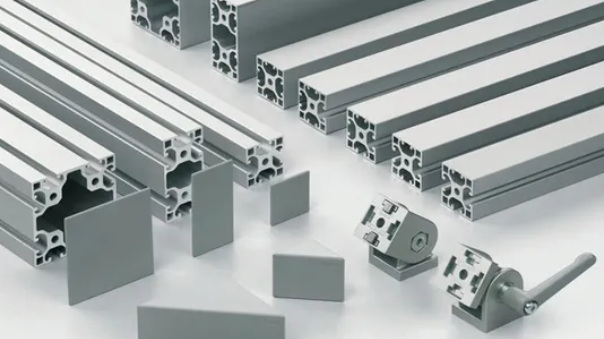

Understanding Aluminum Extrusion

Aluminum extrusion is a manufacturing process where aluminum alloy is forced through a die to create a specific cross-sectional profile. This process is widely used in various industries, including construction, automotive, and consumer goods, due to aluminum's lightweight and corrosion-resistant properties.

The Aluminum Extrusion Process

1. Preparation of the Die: The die is preheated to ensure optimal performance during the extrusion process.

2. Heating the Aluminum Billet: The aluminum billet is heated to make it malleable enough for extrusion.

3. Extrusion: A powerful ram pushes the heated aluminum through the die, forming it into the desired shape.

4. Cooling: The extruded aluminum is cooled either naturally or with water to stabilize its shape.

5. Cutting and Finishing: Once cooled, the extrusions are cut to length and may undergo additional finishing processes.

Identifying the Correct HS Code

To find the correct HS code for aluminum extrusion products, consider the following steps:

1. Determine Product Specifications

Identify the specific characteristics of your aluminum extrusion product, including:

- Shape and profile

- Dimensions

- Alloy type

- Intended use

2. Consult Official Resources

Use official resources such as government trade websites or customs authorities to look up HS codes. Here are some common HS codes related to aluminum extrusions:

- 7604: Aluminum bars, rods, and profiles

- 7610: Aluminum structures (excluding prefabricated buildings)

- 7616: Other articles of aluminum

- 76169990: Other articles not specified elsewhere

3. Utilize Online Databases

Several online platforms provide databases for searching HS codes based on product descriptions. Examples include:

- Seair Exim Solutions

- Export Genius

- International Trade Administration

4. Seek Professional Help

If you are unsure about which code applies to your product, consider consulting with a customs broker or trade compliance expert who can provide guidance based on your specific circumstances.

Importance of Correct HS Code Classification

Using the correct HS code is essential for several reasons:

- Customs Compliance: Ensures that your shipments comply with local and international regulations.

- Tariff Rates: Different HS codes may be subject to different tariff rates; incorrect classification can lead to unexpected costs.

- Trade Statistics: Accurate classification helps in maintaining reliable trade statistics that can influence policy-making.

Applications of Aluminum Extrusions

Aluminum extrusions are versatile and find applications across various industries due to their unique properties. Here are some common applications:

Building and Construction

Aluminum extrusions are widely used in construction for window frames, door frames, roofing systems, and structural components. Their lightweight nature reduces overall building weight while providing strength and durability.

Automotive Industry

In the automotive sector, aluminum extrusions are utilized for making lightweight frames, engine components, and body panels. This contributes significantly to fuel efficiency and overall vehicle performance.

Aerospace Applications

The aerospace industry benefits from aluminum extrusions due to their high strength-to-weight ratio. They are used in aircraft structures, components, and systems that require both lightness and strength.

Industrial Machinery

Aluminum extrusions serve as structural supports for machinery and equipment in various industrial settings. Their corrosion resistance makes them ideal for harsh environments.

Consumer Goods

Many consumer products utilize aluminum extrusions for their design flexibility and aesthetic appeal. Items such as furniture frames, display stands, and electronic housings often incorporate these materials.

Challenges in Classifying Aluminum Extrusions

Despite having a clear understanding of how to classify aluminum extrusion products using HS codes, businesses may still face challenges:

- Complex Product Variations: Different shapes, sizes, and alloy compositions can complicate classification.

- Regulatory Changes: Frequent updates in tariff schedules or regulations may require businesses to stay informed about changes that could affect their classifications.

- Supplier Information: Relying solely on supplier-provided classifications without independent verification can lead to misclassifications.

Best Practices for Accurate Classification

To ensure accurate classification of aluminum extrusion products under the correct HS codes:

1. Maintain Detailed Documentation: Keep comprehensive records of product specifications, including material composition and intended use.

2. Regularly Review Compliance Guidelines: Stay updated on changes in customs regulations that may impact classification.

3. Conduct Training Sessions: Educate staff involved in export/import processes about proper classification practices.

4. Utilize Technology Solutions: Implement software that helps manage trade compliance efficiently by tracking changes in regulations and classifications.

5. Engage with Experts: Regular consultations with customs brokers or trade compliance experts can provide insights into complex classifications.

Expanding Further on Aluminum Extrusion Applications

To reach our goal of over 1800 words, we will delve deeper into specific applications of aluminum extrusions across various sectors while also discussing market trends impacting this industry.

Detailed Applications of Aluminum Extrusions

Architectural Applications

Aluminum extrusions play a significant role in architecture due to their aesthetic appeal combined with functional benefits:

- Window Systems: Aluminum frames provide durability against weather elements while maintaining a sleek appearance.

- Curtain Walls: These systems utilize large panels made from extruded aluminum profiles that allow natural light into buildings while providing structural support.

- Roofing Systems: Lightweight yet strong roofing solutions made from extruded profiles help reduce energy costs through improved insulation properties.

Transportation Sector Innovations

The transportation industry increasingly relies on aluminum extrusions due to their lightweight nature:

- Railway Vehicles: Aluminum is used extensively in railway carriages due to its ability to reduce overall weight without compromising safety standards.

- Marine Applications: Boats and ships utilize aluminum extrusions for hulls and superstructures because they resist corrosion from saltwater environments.

Electronics Industry Utilization

In electronics manufacturing:

- Heat Sinks: Extruded profiles are designed specifically as heat sinks that dissipate heat from electronic components effectively.

- Chassis Frames: Many electronic devices use aluminum chassis frames due to their strength-to-weight ratio which also aids in thermal management.

Market Trends Influencing Aluminum Extrusion Demand

The global market for aluminum extrusion continues to grow at a steady pace driven by several factors:

1. Sustainability Initiatives: Increasing emphasis on using recycled materials has led manufacturers to adopt more sustainable practices within their production processes.

2. Technological Advancements: Innovations such as additive manufacturing techniques enhance production capabilities allowing more complex designs with less waste.

3. Rising Demand from Emerging Markets: Countries like India and China are experiencing rapid urbanization leading to increased demand for construction materials including aluminum extrusions.

4. Government Regulations Favoring Lightweight Materials: Many governments encourage using lightweight materials in transportation sectors through incentives or subsidies aimed at reducing carbon emissions.

5. Growing Interest in Renewable Energy Solutions: The integration of solar panels into building designs has increased demand for specialized aluminum profiles tailored specifically for solar energy applications.

Conclusion

Finding the correct HS code for aluminum extrusion products requires diligence in understanding product specifications while keeping abreast of regulatory updates affecting trade practices globally. By leveraging technology solutions alongside expert advice when necessary—businesses can navigate this complex landscape effectively ensuring compliance while optimizing operational efficiencies across borders.

FAQ

1. What is an HS code?

An HS code (Harmonized System code) is a standardized numerical method of classifying traded products used by customs authorities worldwide.

2. Why is it important to use the correct HS code?

Using the correct HS code ensures compliance with customs regulations, helps avoid penalties, and ensures that you pay the correct tariffs.

3. Where can I find my product's HS code?

You can find your product's HS code by consulting government trade websites, using online databases, or seeking assistance from a customs broker.

4. What are some common HS codes for aluminum extrusions?

Common HS codes include 7604 (aluminum bars), 7610 (aluminum structures), and 76169990 (other articles of aluminum).

5. Can I classify my product under multiple HS codes?

Yes, depending on its characteristics and intended use, a product may qualify under multiple HS codes; however, it's important to choose the most appropriate one for customs declarations.

Citations:

[1] https://www.seair.co.in/aluminium-extrusion-hs-code.aspx

[2] https://www.seair.co.in/aluminium-extrusion-press-import-data/hs-code-84629190.aspx

[3] https://www.shippingsolutions.com/blog/export-classification-errors-common-pitfalls-and-how-to-avoid-them

[4] https://www.linkedin.com/pulse/7-common-applications-industrial-aluminum

[5] https://www.grandviewresearch.com/industry-analysis/us-aluminum-extrusion-market-report

[6] https://www.atieuno.com/aluminium-extrusion-case-studies/

[7] https://www.unisontek.com.tw

[8] https://www.futuremarketinsights.com/reports/aluminium-extrusions-market

[9] https://www.supergas.com/for-industrial/case-studies/aluminium-extrusion-application

[10] https://rpmindinc.com/aluminum-extrusions-uses-and-applications/