Content Menu

● Introduction to Plastic Extrusion Machinery

>> Key Components of a Plastic Extrusion Machine

● Leading Plastic Extrusion Machinery Manufacturers in India

>> Jimkhaas Extrusions

>> Prime Margo Machines

● How to Select High-Quality Plastic Extrusion Machines

>> Understanding the Plastic Extrusion Process

● Benefits of Plastic Extrusion Machinery

● Market Trends and Future Outlook

>> Impact of Technology Advancements

>> Role of Plastic Extrusion Machinery in Sustainable Practices

● Conclusion

● FAQ

>> 1. What are the key factors to consider when selecting a plastic extrusion machine?

>> 2. Which companies are leading plastic extrusion machinery manufacturers in India?

>> 3. How does a plastic extrusion machine work?

>> 4. What are the applications of plastic extrusion machines?

>> 5. Can plastic extrusion machines be customized?

● Citations:

Finding high-quality plastic extrusion machines is crucial for any manufacturing business, especially in regions like Ahmedabad, Gujarat, where the demand for plastic products is high. Samarika Pharma Solutions LLP, although primarily known for pharmaceutical equipment, can provide insights into the broader context of manufacturing high-quality machinery. However, for plastic extrusion machinery, companies like Jimkhaas Extrusions and Prime Margo Machines are more relevant. This article will guide you through the process of selecting the best plastic extrusion machines from leading manufacturers in Ahmedabad and provide insights into what makes a machine high-quality.

Introduction to Plastic Extrusion Machinery

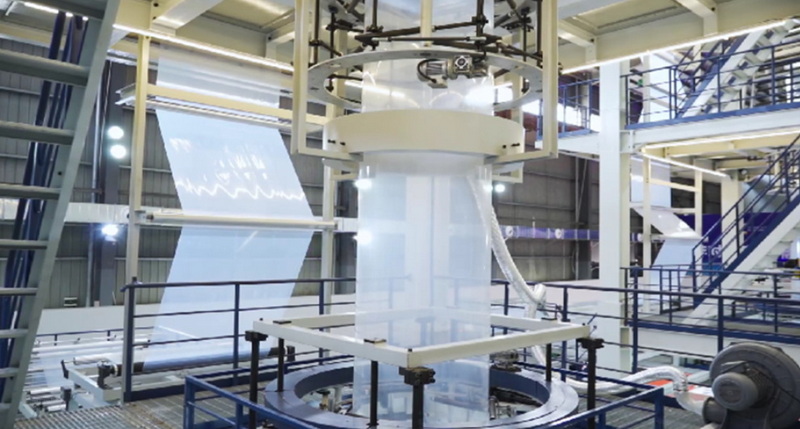

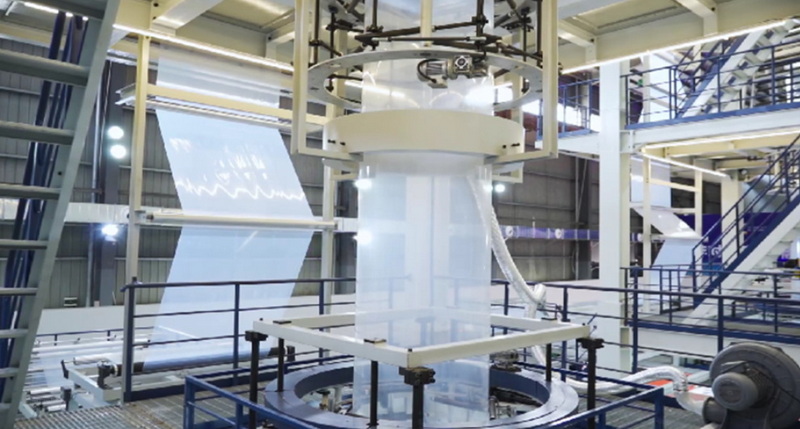

Plastic extrusion is a high-volume manufacturing process used to create continuous profiles of plastic products, such as pipes, tubing, and sheeting. The process involves melting raw plastic material and forcing it through a die to achieve the desired shape. This method is favored for its efficiency and versatility in producing a wide range of plastic products.

Key Components of a Plastic Extrusion Machine

A typical plastic extrusion machine consists of several critical components:

- Hopper: Where raw plastic material is loaded.

- Barrel: Houses the extruder screw and is equipped with heaters.

- Extruder Screw: Pushes the plastic through the barrel, generating heat through friction.

- Die: Shapes the molten plastic into the desired profile.

- Cooling System: Solidifies the extruded plastic.

- Cutter: Cuts the product into required lengths.

Understanding these components is essential for optimizing production processes and ensuring the quality of the final product.

Leading Plastic Extrusion Machinery Manufacturers in India

Jimkhaas Extrusions

Jimkhaas Extrusions is a prominent manufacturer of plastic extrusion machinery in Ahmedabad. They offer a range of machines, including HDPE and PVC pipe extruders, designed with advanced technology for high-quality output and efficiency.

Key Features of Jimkhaas Extrusions:

- Advanced Technology: Ensures precision and high-speed production.

- Efficient Production: Maximizes output while minimizing energy consumption.

- Durability & Reliability: Built with high-quality materials for minimal maintenance.

- Customization Options: Available for specific production requirements.

Jimkhaas Extrusions focuses on delivering machines that meet international standards, ensuring that customers receive products that are both reliable and efficient.

Prime Margo Machines

Prime Margo Machines is another leading manufacturer, offering a wide range of plastic extrusion machinery, including HDPE and PVC pipe plants. They focus on reducing costs and increasing productivity.

Key Features of Prime Margo Machines:

- Quality and Innovation: Focus on delivering high-quality machines with advanced technology.

- Global Reach: Exports to multiple countries, serving both domestic and international markets.

- Custom Solutions: Offers tailored machines to meet specific customer needs.

Prime Margo Machines emphasizes customer satisfaction by providing comprehensive after-sales support and maintenance services.

How to Select High-Quality Plastic Extrusion Machines

When selecting a plastic extrusion machine, several factors should be considered:

1. Type of Plastic Material: Ensure the machine is compatible with the material you plan to use.

2. Production Capacity: Aligns with your production needs.

3. Energy Efficiency: Reduces operational costs and supports sustainability.

4. Maintenance and Serviceability: Easy maintenance reduces downtime.

5. Supplier Reputation: Choose a reputable supplier with good customer service.

Understanding the Plastic Extrusion Process

The plastic extrusion process involves several stages:

- Material Preparation: Ensuring the raw material is clean and dry.

- Melting: The plastic is melted in the barrel.

- Forming: The molten plastic is forced through the die.

- Cooling: The extruded product is cooled and solidified.

- Cutting: The final product is cut to the required length.

Understanding these stages helps in optimizing production processes and ensuring high-quality output.

Benefits of Plastic Extrusion Machinery

Plastic extrusion machinery offers several benefits:

- High Production Volume: Ideal for mass production.

- Versatility: Can produce a wide range of plastic products.

- Cost-Effective: Reduces labor costs compared to manual processes.

- Consistency: Ensures consistent product quality.

Market Trends and Future Outlook

The demand for plastic extrusion machinery is expected to grow due to increasing demand for plastic products in various industries. Manufacturers are focusing on developing more energy-efficient and sustainable machines to meet environmental regulations and consumer preferences.

Impact of Technology Advancements

Advancements in technology have significantly improved the efficiency and precision of plastic extrusion machines. Modern machines are equipped with advanced control systems, allowing for real-time monitoring and adjustments, which enhance product quality and reduce waste.

Role of Plastic Extrusion Machinery in Sustainable Practices

While plastic production is often associated with environmental concerns, plastic extrusion machinery can play a role in sustainable practices by:

- Reducing Waste: Efficient production minimizes waste.

- Recycling: Some machines can process recycled plastic materials.

- Energy Efficiency: Modern machines are designed to consume less energy.

Conclusion

Finding high-quality plastic extrusion machines in Ahmedabad involves researching reputable manufacturers like Jimkhaas Extrusions and Prime Margo Machines. These companies offer advanced technology, customization options, and reliable machinery that can enhance your production capabilities. While Samarika Pharma Solutions LLP is not directly involved in plastic extrusion machinery, understanding the broader context of manufacturing high-quality machinery can be beneficial.

FAQ

1. What are the key factors to consider when selecting a plastic extrusion machine?

The key factors include the type of plastic material, production capacity, energy efficiency, maintenance requirements, and supplier reputation.

2. Which companies are leading plastic extrusion machinery manufacturers in India?

Leading manufacturers include Jimkhaas Extrusions and Prime Margo Machines, known for their advanced technology and customization options.

3. How does a plastic extrusion machine work?

A plastic extrusion machine works by melting raw plastic material and forcing it through a die to create the desired shape. The process involves several components, including a hopper, barrel, extruder screw, die, cooling system, and cutter.

4. What are the applications of plastic extrusion machines?

Plastic extrusion machines are used in various industries, including construction, packaging, and manufacturing, to produce items like pipes, tubing, and sheeting.

5. Can plastic extrusion machines be customized?

Yes, many manufacturers offer customization options to meet specific production requirements, such as pipe sizes and production speeds.

Citations:

[1] https://www.jimkhaasextrusions.in/extrusion-machine.html

[2] https://www.hrplastic.in/plastic-dana-machine-plant.html

[3] https://primemargo.com

[4] https://plasticextrusionplant.in/plastic-extrusion-plant.php

[5] https://www.youtube.com/watch?v=oYgtuEQjEEA

[6] https://ud-machine.com/blog/extrusion-machine-manufacturers-in-india/

[7] https://jieyatwinscrew.com/blog/everything-you-need-to-know-about-plastic-extrusion-machines/

[8] https://samarika.com

[9] https://www.panchveerengineering.com

[10] https://plasticextrusionplant.in

[11] https://ensun.io/search/plastic-extrusion/india

[12] https://jjindustriesindia.com/plastic-extrusion-machine-faqs/

[13] https://samarika.com

[14] https://www.samrikaflexitech.com

[15] https://www.indiamart.com/proddetail/dwc-corrugator-machine-die-24760055588.html

[16] https://www.indiamart.com/samrikaflexitechindustries/

[17] https://dir.indiamart.com/ahmedabad/plastic-extrusion-machines.html

[18] https://www.bharatibiz.com/en/plastic-extrusion-machinery-095583-38489

[19] https://www.justdial.com/Gandhinagar-Gujarat/Grinding-Machine-Manufacturers-in-Gandhinagar-Sector-2/nct-10237604

[20] https://plasticextrusionplant.in/jockey-extruder.php

[21] https://www.justdial.com/jdmart/Ahmedabad/Plastic-Extrusion-Wholesalers/jdm-1083449-ent-6-22756518

[22] https://www.maahiextrusion.com/plastic-extrusion-machine.html

[23] https://www.tradeindia.com/manufacturers/plastic-film-extruder.html

[24] https://www.justdial.com/Ahmedabad/Plastic-Extruder-Machine-Manufacturers-in-Prahladnagar/nct-10375270

[25] https://www.vrundavanplasticengg.com/hdpe-extrusion-machine-7006434.html

[26] https://www.tradeindia.com/products/aglomerator-machine-744482.html

[27] https://bazar.preciousplastic.com/machines/extruder/

[28] https://www.justdial.com/Ahmedabad/Blown-Film-Extrusion-Machine-Manufacturers/nct-11456944

[29] https://www.plasticrecyclingmachineries.com

[30] https://www.vrundavanengg.com