Content Menu

● Understanding Aluminum Extrusion

● The Aluminum Extrusion Process

● Why Choose Aluminum Extrusion?

● Finding High-Quality Aluminum Extruders in Charlotte, NC

● Specific Considerations for Charlotte, NC

● Examples of Aluminum Extruders

● The Importance of a Strong Partnership

● The Role of Aluminum Fabrication

● Best Practices in Aluminum Fabrication

● The Future of Aluminum Extrusion

● Conclusion

● FAQ

>> 1. What are the benefits of using aluminum extrusions?

>> 2. What types of aluminum alloys are commonly used in extrusion?

>> 3. What secondary services should I look for in an aluminum extruder?

>> 4. How do I ensure the quality of aluminum extrusions?

>> 5. What is the difference between direct and indirect extrusion?

● Citations:

Aluminum extrusion is a versatile manufacturing process used to create a wide array of products with specific cross-sectional profiles. From aerospace and automotive to construction and electronics, aluminum extrusions are integral to numerous industries[1]. Finding a high-quality aluminum extruder in Charlotte, NC requires careful consideration of several factors, including their capabilities, experience, quality control measures, and customer service. This article will guide you through the process of identifying the best aluminum extrusion partners in the Charlotte area.

Understanding Aluminum Extrusion

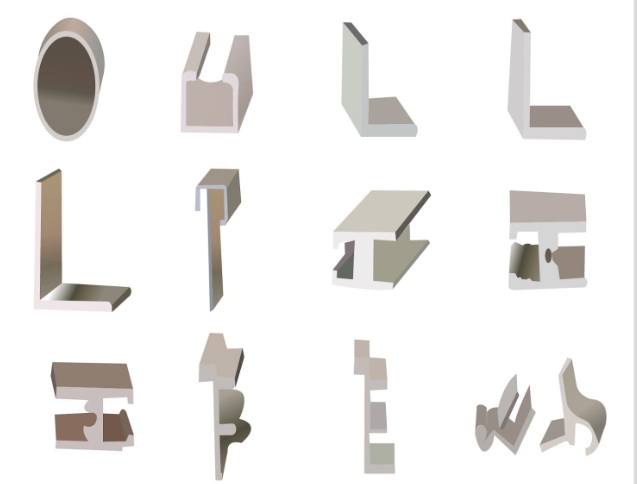

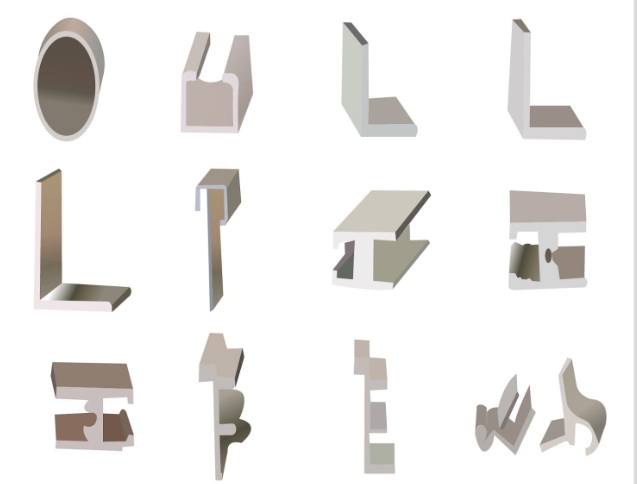

Before diving into how to find the right extruder, it's important to understand the aluminum extrusion process itself. Aluminum extrusion involves forcing aluminum alloy through a die with a specific cross-sectional profile[9]. This process creates parts with consistent shapes and dimensions, making it ideal for various applications.

The Aluminum Extrusion Process

1. Die Preparation: The process begins with designing and manufacturing a die that matches the desired profile of the extrusion[5]. The die is a specialized tool with an opening that the aluminum will be pushed through.

2. Billet Preparation: Raw aluminum alloy is formed into cylindrical blocks called billets[5]. These billets are cut to specific lengths and preheated to temperatures between 450 to 500 degrees Celsius to make them soft enough for extrusion[9].

3. Extrusion: The heated billet is loaded into an extrusion press. There are two main extrusion processes:

- Direct Extrusion: The billet is placed inside a heated container, and a ram pushes the aluminum through the die[9]. Both the ram and the billet move in a forward direction.

- Indirect Extrusion: The die is stationary, while the aluminum billet and container move together[9]. This method is often preferred for complex profiles and tighter tolerances[8].

4. Cooling: As the aluminum emerges from the die, it's cooled using air or water[5]. This step solidifies the shape and maintains its dimensional accuracy.

5. Stretching: After cooling, the extrusion may be stretched to straighten it and improve its mechanical properties.

6. Cutting & Finishing: The extrusion is cut to the desired length and may undergo additional finishing processes such as machining, deburring, or surface treatments[3][8].

Why Choose Aluminum Extrusion?

- Versatility: Aluminum can be extruded into a wide variety of complex shapes and profiles[3][8].

- Strength-to-Weight Ratio: Aluminum is strong yet lightweight, making it ideal for applications where weight is a concern[1].

- Corrosion Resistance: Aluminum naturally forms a protective oxide layer, making it resistant to corrosion[1].

- Recyclability: Aluminum is 100% recyclable without losing its properties.

- Cost-Effectiveness: Aluminum extrusion can be a cost-effective manufacturing process, especially for large production runs.

Finding High-Quality Aluminum Extruders in Charlotte, NC

Now, let's explore the key steps in finding the right aluminum extruder in Charlotte, NC:

1. Define Your Project Requirements:

- Extrusion Type: Determine the type of extrusion needed (solid, hollow, semi-hollow)[7].

- Alloy Selection: Different aluminum alloys offer varying properties. Consider strength, corrosion resistance, weldability, and machinability[1]. Common alloys include 1100, 3003, 6061, 6063, and 6463[3].

- Dimensional Tolerances: Specify the required dimensional tolerances for your project[3].

- Finishing Requirements: Determine if you need any additional finishing services such as anodizing, powder coating, or painting[8][12].

- Volume: Estimate the production volume to ensure the extruder can meet your needs.

2. Research Potential Extruders:

- Online Directories: Use online directories such as IQS Directory and ThomasNet to find aluminum extrusion manufacturers serving North Carolina[6][7].

- Local Manufacturers: Search specifically for "aluminum extruder Charlotte NC" to find local companies.

- Company Websites: Visit the websites of potential extruders to learn more about their capabilities, experience, and certifications.

- Customer Reviews: Look for customer reviews and testimonials to gauge the extruder's reputation.

3. Evaluate Extruder Capabilities:

- Extrusion Presses: Check the size and capacity of their extrusion presses[5][9].

- Alloy Range: Ensure they can work with the specific aluminum alloys required for your project[3].

- Tolerance Capabilities: Verify their ability to meet your dimensional tolerance requirements[3].

- In-House Services: Determine if they offer in-house services such as design assistance, fabrication, and finishing[2][3][8].

- Certifications: Look for certifications such as AS9100 and ISO9001, which indicate a commitment to quality[3].

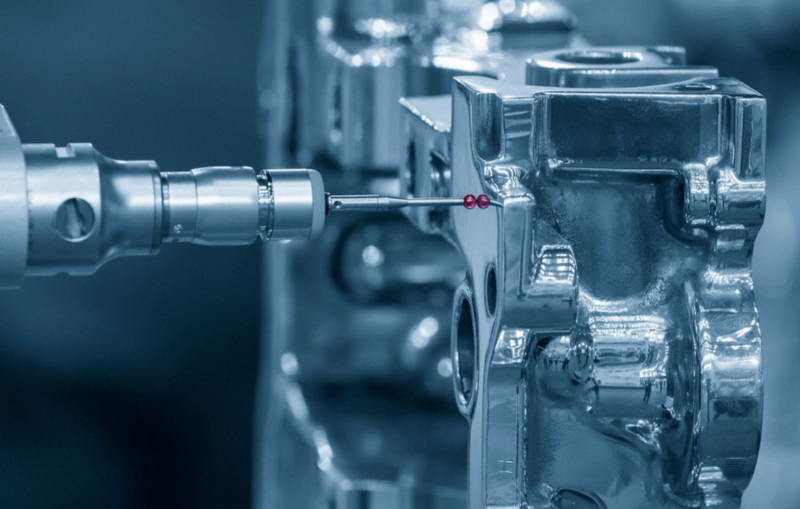

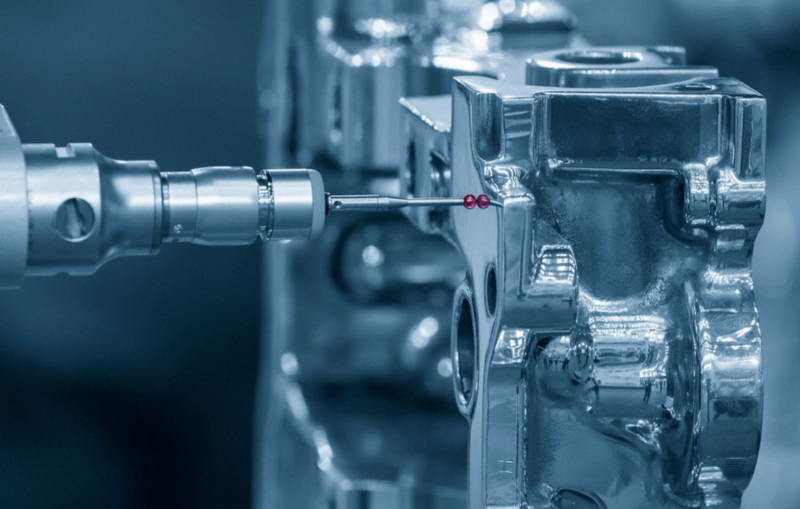

4. Assess Quality Control Measures:

- Material Traceability: Ensure the extruder has systems in place to track the materials used in the extrusion process.

- Dimensional Inspection: Ask about their dimensional inspection processes and equipment[1].

- Process Control: Determine if they have documented procedures for process control and quality assurance[1].

5. Request Quotes and Lead Times:

- Detailed RFQ: Provide potential extruders with a detailed Request for Quote (RFQ) that includes all project requirements.

- Compare Quotes: Compare quotes from multiple extruders, considering price, lead time, and services offered.

- Lead Times: Inquire about lead times to ensure they align with your project timeline.

6. Visit the Facility (If Possible):

- Facility Tour: If feasible, schedule a visit to the extruder's facility to assess their equipment, processes, and quality control measures.

- Meet the Team: Meet with the extruder's team to discuss your project and assess their expertise and responsiveness.

7. Consider Value-Added Services:

- Design Assistance: Some extruders offer design assistance to optimize your extrusion profile for manufacturability and performance[8].

- Fabrication: Determine if the extruder can provide fabrication services such as cutting, drilling, and machining[2][8][10].

- Finishing: Inquire about finishing options such as anodizing, powder coating, and painting[2][8][12].

- Assembly: Some extruders can provide assembly services to deliver complete components or products[2].

Specific Considerations for Charlotte, NC

- Local Expertise: Prioritize extruders with a strong understanding of the Charlotte, NC market and its specific industry needs.

- Proximity: Consider the extruder's location in relation to your facility to minimize transportation costs and lead times.

- Industry Focus: Look for extruders with experience serving industries relevant to your business (e.g., aerospace, automotive, construction)[1].

Examples of Aluminum Extruders

- Roberson Machine Company: While not located directly in Charlotte, NC, Roberson Machine Company provides aluminum fabrication services to the area[1].

- IPC Corporation: Specializes in extruded aluminum metal products, including custom extrusions and fabrication services[2].

- Minalex: Delivers high-quality custom aluminum extrusions with a focus on precision and value-added services[3].

- Profile Custom Extrusions, LLC: Offers a comprehensive range of custom aluminum extrusions and related services[4].

- Alfiniti, Inc.: Manufacturer of aluminum drawn tubing, cold drawn tube, and extrusions[7][11].

The Importance of a Strong Partnership

Finding a high-quality aluminum extruder is not just about finding a supplier; it's about building a strong partnership. A good extruder will work closely with you to understand your project requirements, provide design assistance, and ensure that your extrusions meet your exact specifications. They will also be responsive to your needs and provide excellent customer service.

The Role of Aluminum Fabrication

Aluminum fabrication is closely related to extrusion. While extrusion creates the initial profile, fabrication involves further processing to create finished parts[1]. This can include cutting, machining, welding, and assembly. Many aluminum extruders also offer fabrication services, providing a one-stop shop for your aluminum component needs.

Best Practices in Aluminum Fabrication

- Selecting the Right Alloy: Choosing the appropriate aluminum alloy is crucial for the success of your fabrication project[1].

- Maintaining Proper Tooling and Equipment: Using sharp, well-maintained tools is essential for achieving precise cuts and minimizing burrs.

- Ensuring Precision and Accuracy: Precision machining techniques are vital for achieving the desired function, form, and fit of your fabricated components[1].

- Implementing Quality Control Measures: Rigorous quality control measures are necessary to ensure that fabricated parts meet your specifications[1].

The Future of Aluminum Extrusion

The aluminum extrusion industry is constantly evolving, with new technologies and techniques emerging to improve efficiency, precision, and sustainability. Some of the trends shaping the future of aluminum extrusion include:

- Advanced Alloys: Development of new aluminum alloys with improved strength, corrosion resistance, and other properties.

- Automation: Increased automation of the extrusion process to improve efficiency and reduce costs.

- Digitalization: Use of digital technologies such as simulation and modeling to optimize the extrusion process and design.

- Sustainability: Focus on sustainable practices such as recycling and reducing energy consumption.

Conclusion

Finding a high-quality aluminum extruder in Charlotte, NC requires careful research and evaluation. By understanding the aluminum extrusion process, defining your project requirements, and assessing potential extruders based on their capabilities, quality control measures, and customer service, you can find the right partner to meet your needs. Remember to consider value-added services such as design assistance, fabrication, and finishing to streamline your supply chain and ensure the success of your project. Building a strong partnership with your chosen extruder will be essential for achieving your goals and staying ahead in today's competitive market.

FAQ

1. What are the benefits of using aluminum extrusions?

Aluminum extrusions offer numerous benefits, including versatility, a high strength-to-weight ratio, corrosion resistance, recyclability, and cost-effectiveness. They can be used in a wide range of applications across various industries.

2. What types of aluminum alloys are commonly used in extrusion?

Common aluminum alloys used in extrusion include 1100, 3003, 6061, 6063, and 6463. Each alloy offers different properties in terms of strength, corrosion resistance, weldability, and machinability[3].

3. What secondary services should I look for in an aluminum extruder?

In addition to extrusion, consider extruders that offer secondary services such as design assistance, fabrication (cutting, drilling, machining), and finishing (anodizing, powder coating, painting)[2][3][8].

4. How do I ensure the quality of aluminum extrusions?

Ensure the extruder has robust quality control measures in place, including material traceability, dimensional inspection, and process control. Look for certifications such as AS9100 and ISO9001[1][3].

5. What is the difference between direct and indirect extrusion?

In direct extrusion, the billet is pushed through the die by a moving ram. In indirect extrusion, the die moves while the billet remains stationary[9]. Indirect extrusion is often preferred for complex profiles and tighter tolerances.

Citations:

[1] https://robersontool.com/aluminum-fabrication/charlotte-nc/

[2] https://ipccorp.net

[3] https://www.minalex.com

[4] https://aluminum-extrusions.net/category/north-carolina/

[5] https://www.youtube.com/watch?v=iiGlq7408ME

[6] https://www.iqsdirectory.com/aluminum-extrusions/north-carolina/

[7] https://www.thomasnet.com/suppliers/north-carolina/all-cities/aluminum-extruded-shapes-1390806

[8] https://paramountextrusions.com

[9] https://www.youtube.com/watch?v=ELgtjeJyFw8

[10] https://www.keypointfab.com

[11] https://alfiniti.com

[12] https://alfiniti.com/aluminum-supplier-manufacturer/

[13] https://www.youtube.com/watch?v=baM5hNnBcT8

[14] https://www.thomasnet.com/suppliers/north-carolina/charlotte/aluminum-fabrication-1420207

[15] https://www.hydro.com/en/global/about-hydro/hydro-worldwide/americas/united-states/southeast/hydro-burlington-nc/

[16] https://www.excellart.com

[17] https://americanmetals.us

[18] https://www.thomasnet.com/suppliers/north-carolina/all-cities/aluminum-extrusions-26890400

[19] https://www.carolinafluidcomponents.com/80-20-extruded-t-slot-aluminum

[20] https://www.alineautomation.com

[21] https://www.ryerson.com/locations/united-states/north-carolina/charlotte

[22] https://www.odmetals.com/about

[23] https://www.easternmetal.com

[24] https://leonardfabdesign.com/gallery/

[25] https://aluminum-extrusions.net/gallery/

[26] https://www.youtube.com/watch?v=DqILlMsNYLw

[27] https://fab-tec.com/machining-fabrication/

[28] https://www.youtube.com/watch?v=P8BWQBP4Vhk

[29] https://metal-fabricators.org/aluminum-fabricators-gallery/

[30] https://www.instagram.com/customrecycling/p/CE4iJ_UDZcX/

[31] https://www.youtube.com/watch?v=Bc7o_sEdX8U

[32] https://andronx.com/metal-fabrication/

[33] https://taberextrusions.com

[34] https://www.linkedin.com/pulse/aluminum-extrusion-process-10-steps-video-clips-nomexfelt

[35] https://technical.europe.misumi-ec.com/en/support/solutions/articles/76000046645-aluminum-extrusions-general-questions

[36] https://www.minalex.com/2021/10/29/10-questions-ask-aluminum-extruder/

[37] https://aec.org/faqs

[38] https://profileprecisionextrusions.com/5-initial-questions-ask-aluminum-extruder/

[39] https://www.uniqueextrusions.com/aluminum-extrusion-faq/

[40] https://www.approvedsheetmetal.com/blog/4-things-know-about-aluminum-fabrication

[41] https://edmolimited.co.uk/education/frequently-asked-questions/aluminium-extrusion/

[42] https://www.aldinemetal.com/resources/blogs/materials/aluminum/what-do-you-need-to-know-before-fabricating-aluminum/

[43] https://zjaluminum-cnc.com/faqs-on-aluminum-extrusion-and-fabrication/

[44] http://www.aluminiumfabrication.org.uk/aluminium-fabrication-faq.html

[45] https://spectraaluminum.com/frequently-asked-questions-about-aluminum-extrusion/

[46] https://impactfab.com/aluminum-fabrication-everything-you-need-to-know

[47] https://aluminum-extrusions.net/category/north-carolina/

[48] https://starext.com/news/aluminum-extrusion-finishing-fabrication-frequently-asked-questions-faq

[49] https://www.impol.com/everything-you-need-to-know-about-aluminum-extrusion/

[50] https://www.worthyhardware.com/news/everything-you-need-to-know-about-aluminum-fabrication/

[51] https://starext.com/frequently-asked-questions-about-aluminum-extrusions

[52] https://dajcor.com/learning-centre/faq

[53] https://www.alufabinc.com/faqs/

[54] https://topweld.com.au/aluminum-fabrication-basic-guide/

[55] https://shengenfab.com/aluminum-fabrication/