Content Menu

● Introduction to HDPE Sheet Extrusion Machinery

>> Key Components of HDPE Sheet Extrusion Machinery

● Factors to Consider When Buying Affordable HDPE Sheet Line Extrusion Machinery

● Market Options for Affordable HDPE Sheet Line Extrusion Machinery

● Tips for Negotiating the Best Price

● Maintenance and Upkeep of HDPE Sheet Extrusion Machinery

● Market Trends and Innovations

● Top Manufacturers in the Industry

● Conclusion

● FAQs

>> 1. What is the typical production capacity of HDPE sheet extrusion machinery?

>> 2. How does the automation level affect the cost of HDPE sheet extrusion machinery?

>> 3. Can HDPE sheet extrusion machinery process other materials besides HDPE?

>> 4. What are the advantages of buying used HDPE sheet extrusion machinery?

>> 5. How important is after-sales support when purchasing HDPE sheet extrusion machinery?

● Citations:

In the rapidly evolving world of plastics manufacturing, finding affordable yet efficient HDPE sheet line extrusion machinery is crucial for businesses aiming to stay competitive. High-density polyethylene (HDPE) sheets are widely used in various industries, including construction, packaging, and consumer products, due to their durability and versatility. This article will guide you through the process of selecting and purchasing cost-effective HDPE sheet extrusion machinery, highlighting key considerations and market options.

Introduction to HDPE Sheet Extrusion Machinery

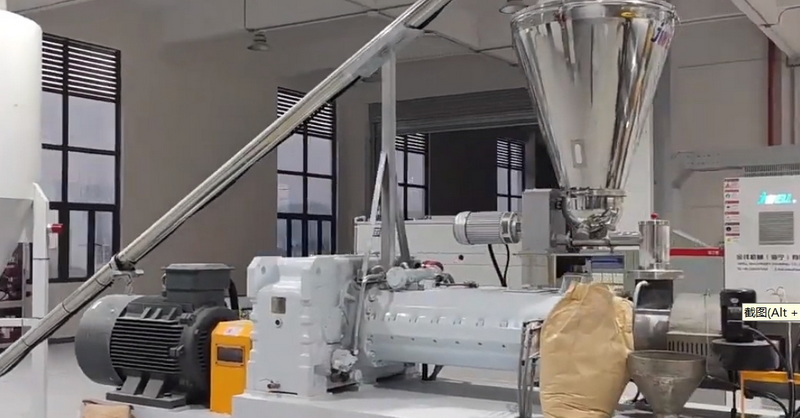

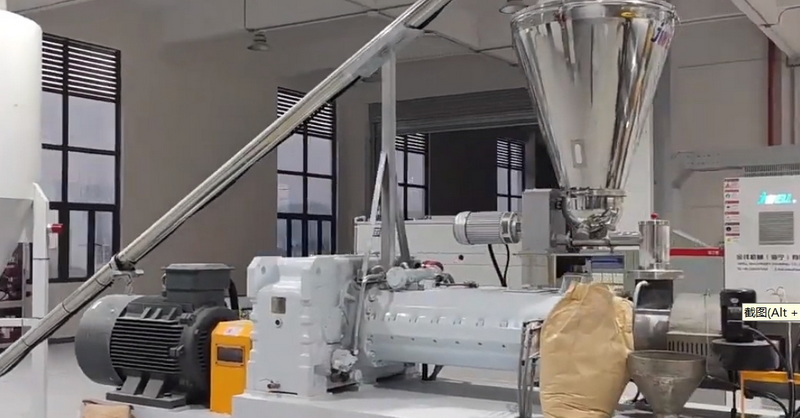

HDPE sheet extrusion machinery is designed to convert HDPE pellets into sheets of varying thicknesses and widths. The process involves feeding the pellets into an extruder, where they are melted and formed into a sheet through a die. The sheet is then cooled and cut to the desired size.

Key Components of HDPE Sheet Extrusion Machinery

1. Extruder: This is the heart of the machine, responsible for melting and homogenizing the HDPE material.

2. Die: Shapes the molten HDPE into a sheet.

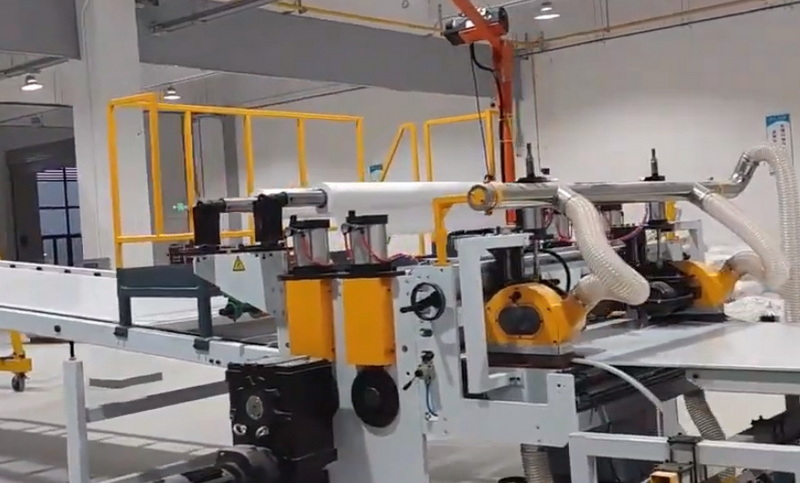

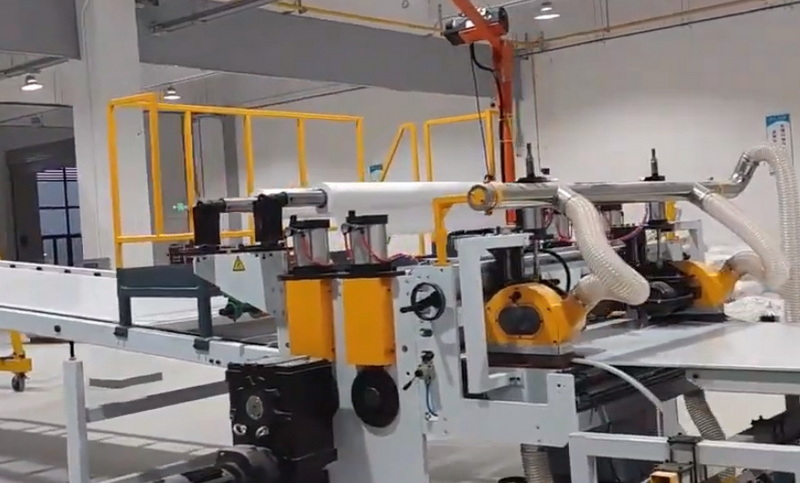

3. Chill Rolls: Cool and solidify the sheet.

4. Cutting Machine: Cuts the sheet to the desired length.

Factors to Consider When Buying Affordable HDPE Sheet Line Extrusion Machinery

When searching for cheap HDPE sheet line extrusion machinery prices, several factors must be considered to ensure you get the best value for your investment:

1. Production Capacity: Determine how much HDPE sheet you need to produce per hour. Machines with higher capacities often cost more but may be more cost-effective in the long run.

2. Automation Level: Fully automatic machines are more efficient but typically more expensive than semi-automatic or manual ones.

3. Material Compatibility: Ensure the machine can handle HDPE and possibly other materials if needed.

4. Power Consumption: Lower power consumption can lead to cost savings over time.

5. Brand and Quality: Reputable brands often provide better durability and after-sales support.

6. Export Options: If you plan to export your products, ensure the machinery meets international standards.

Market Options for Affordable HDPE Sheet Line Extrusion Machinery

The market offers a variety of options for cheap HDPE sheet line extrusion machinery prices:

1. New Machinery: Purchasing new machinery ensures you get the latest technology and warranty support.

2. Used Machinery: Buying used machinery can be cost-effective but requires careful inspection to ensure it is in good working condition.

3. Local vs. International Suppliers: Local suppliers may offer quicker delivery and easier maintenance, while international suppliers might provide more competitive pricing.

Tips for Negotiating the Best Price

1. Compare Prices: Research different suppliers to find the best deal.

2. Negotiate: Don't hesitate to negotiate, especially when purchasing from local suppliers.

3. Consider Bundles: Buying multiple machines or accessories together might reduce the overall cost.

4. Look for Discounts: Keep an eye out for seasonal discounts or promotions.

Maintenance and Upkeep of HDPE Sheet Extrusion Machinery

Proper maintenance is crucial to extend the lifespan of your machinery and ensure consistent production quality. Here are some tips:

1. Regular Lubrication: Ensure all moving parts are well-lubricated to prevent wear and tear.

2. Winter Maintenance: Drain water from pumps and vacuum systems to prevent freezing during winter[7].

3. Spare Parts Management: Keep spare parts on hand for quick repairs and minimize downtime[3].

4. Energy Efficiency: Opt for energy-efficient machines to reduce operational costs and environmental impact[6].

Market Trends and Innovations

The HDPE sheet extrusion industry is witnessing significant advancements:

1. Digital Control Systems: Modern machines often feature advanced digital control systems that enhance automation and product consistency.

2. Sustainability: There is a growing focus on using recycled materials in HDPE sheet production without compromising quality[5].

3. Energy Efficiency: Machines are being designed to be more energy-efficient, reducing operational costs and environmental impact[6].

Top Manufacturers in the Industry

Some of the leading manufacturers of plastic extrusion machinery include:

1. YeJing: Known for their twin-screw extruders used in the plastic and pharmaceutical industries[8].

2. Reifenhauser: Offers a wide range of extrusion solutions for various applications[8].

3. JWELL Machinery: Specializes in energy-efficient extrusion lines for HDPE and other materials[6].

Conclusion

Finding affordable HDPE sheet line extrusion machinery requires careful consideration of production needs, machinery specifications, and market options. By understanding the key components of HDPE sheet extrusion machinery and considering factors like production capacity and automation level, businesses can make informed decisions that balance cost and efficiency. Whether opting for new or used machinery, local or international suppliers, the goal is to achieve high-quality HDPE sheets at a cheap HDPE sheet line extrusion machinery price.

FAQs

1. What is the typical production capacity of HDPE sheet extrusion machinery?

HDPE sheet extrusion machinery can have a production capacity ranging from 100 kg/hr to over 400 kg/hr, depending on the specific model and application.

2. How does the automation level affect the cost of HDPE sheet extrusion machinery?

Fully automatic machines are generally more expensive than semi-automatic or manual ones due to their higher efficiency and reduced labor requirements.

3. Can HDPE sheet extrusion machinery process other materials besides HDPE?

Yes, some machines are capable of processing other materials like PP, PS, PET, and PVC, making them versatile for different applications.

4. What are the advantages of buying used HDPE sheet extrusion machinery?

Buying used machinery can be cost-effective and environmentally friendly, but it requires thorough inspection to ensure the machinery is in good working condition.

5. How important is after-sales support when purchasing HDPE sheet extrusion machinery?

After-sales support is crucial as it ensures timely maintenance and repair services, which can significantly impact the machinery's lifespan and performance.

Citations:

[1] https://qdkechengda.en.made-in-china.com/product/vdnTrUODXRhe/China-PE-Sheet-PP-Sheet-HDPE-Sheet-Production-Line-Plastic-Plate-Making-Machine-Price-Plastic-Sheet-Extrusion-Machine.html

[2] https://www.yeshaengineering.com/sheet-extrusion-line.html

[3] https://www.jwellextrusions.com/tips-for-maintaining-plastic-extrusion-equipment-in-winter.html

[4] https://www.arlingtonmachinery.com/plastic-extruder/pl.c.1047.0/sheet-extrusion-lines/

[5] https://www.alibaba.com/showroom/hdpe-sheet-extrusion-machine.html

[6] https://www.jwellextrusions.com/products/hdpe-pipe-extrusion-machine/

[7] https://www.jwellmachine.com/winter-maintenance-tips-for-plastic-extrusion-equipment/

[8] https://www.cowellextrusion.com/top-10-plastic-extrusion-machine-manufacturers/

[9] https://www.universalplastics.com/case-studies/

[10] https://provprocure.com/hdpe-sheet-a-complete-guide/

[11] https://www.futuremarketinsights.com/reports/plastic-extrusion-machine-market

[12] https://www.alibaba.com/showroom/hdpe-sheet-making-machine.html

[13] https://www.cowellextrusion.com/everything-you-need-to-know-about-sheet-extrusion-a-comprehensive-guide/

[14] https://belling-machine.en.made-in-china.com/product/QjIxcGMlYwVn/China-High-Efficiency-Plastic-HDPE-PE-Pipe-Extrusion-Production-Line.html

[15] https://www.sheetcoextrusion.com/hdpe-geomembrane-sheet-extrusion-machinery/

[16] https://www.alliedmarketresearch.com/plastic-extrusion-machine-market

[17] https://www.heavenextrusions.com/pp-hdpe-sheet-extrusion-machine

[18] https://www.maintwiz.com/daily-maintenance-checklist-for-extruders/

[19] https://www.jwellextrusions.com/products/extrusion-line/

[20] https://www.alibaba.com/product-detail/_1600132803913.html