Content Menu

● Understanding 8020 T-Slot Aluminum Extrusion

● Planning Your DIY Project

● Tools You Will Need

● Step-by-Step Assembly Guide

>> 1. Cutting the Aluminum Extrusions

>> 2. Layout Your Pieces

>> 3. Use Fasteners and Connectors

>> 4. Assemble the Frame

>> 5. Check Alignment

>> 6. Final Touches

● Practical Applications of 8020 T-Slot Aluminum Extrusion

● Design Ideas Using 8020 T-Slot Aluminum Extrusion

● Tips for Successful Projects

● Maintenance Tips for Longevity

● Conclusion

● Frequently Asked Questions

>> 1. What Is 8020 T-Slot Aluminum Extrusion?

>> 2. What Are Common Uses for 8020 Aluminum?

>> 3. How Do I Cut 8020 Aluminum Extrusion?

>> 4. What Fasteners Do I Need?

>> 5. Can I Modify My Design After Assembly?

8020 T-slot aluminum extrusion is a versatile and robust building material that has gained popularity in various industries, particularly among DIY enthusiasts. Its unique design allows for easy assembly and modification, making it ideal for a wide range of projects. In this article, we will explore how to effectively use 8020 T-slot aluminum extrusion for DIY projects, providing a comprehensive guide that includes design ideas, assembly tips, and practical applications.

Understanding 8020 T-Slot Aluminum Extrusion

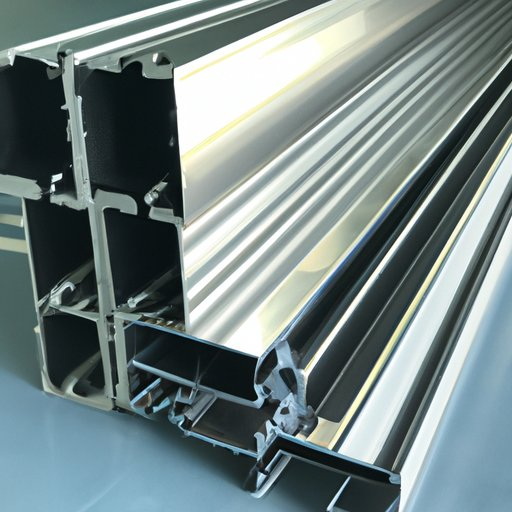

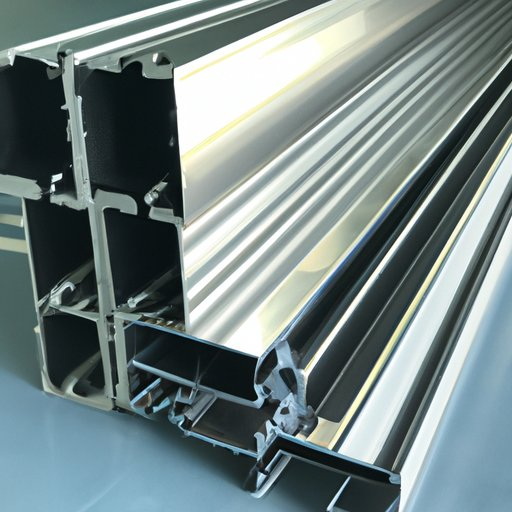

8020 T-slot aluminum extrusion consists of aluminum profiles with a T-shaped groove running along the length. This design allows for the insertion of fasteners and connectors, enabling users to create custom structures easily. The benefits of using 8020 aluminum include:

- Lightweight: Aluminum is significantly lighter than steel, making it easier to handle and transport.

- Durability: Aluminum is resistant to corrosion and wear, ensuring that your projects last longer.

- Flexibility: The modular nature of T-slot extrusions allows for endless configurations and adaptations.

- Ease of Assembly: The T-slot design simplifies the process of connecting different components without the need for complex tools or extensive fabrication skills.

Planning Your DIY Project

Before diving into your project, careful planning is essential. Here are some steps to consider:

1. Define Your Purpose: Determine what you want to build—whether it's a workbench, a frame for a 3D printer, or a custom shelving unit.

2. Sketch Your Design: Create a rough sketch of your project. This will help you visualize the dimensions and layout.

3. Calculate Material Requirements: Measure the lengths needed for each piece of extrusion and calculate how much material you will need.

4. Select Components: Choose the appropriate connectors, fasteners, and accessories based on your design.

5. Budgeting: Consider your budget for materials and tools. While 8020 aluminum can be more expensive than other materials, its durability and versatility often justify the investment.

Tools You Will Need

To work with 8020 T-slot aluminum extrusion effectively, you will need some basic tools:

- Miter saw or band saw for cutting aluminum

- Drill with metal drill bits

- Wrenches or socket set for tightening fasteners

- Level and square for alignment

- Safety gear (goggles, gloves)

- Measuring tape

- Marker or scribe for marking cuts

Step-by-Step Assembly Guide

1. Cutting the Aluminum Extrusions

Cut the aluminum extrusions to the desired lengths using a miter saw or band saw. Ensure you wear safety goggles and follow proper cutting techniques to avoid injury. When cutting, make sure to measure accurately and mark your cuts clearly to ensure precision.

2. Layout Your Pieces

Lay out all cut pieces according to your design plan. This pre-assembly step helps ensure everything fits correctly before final assembly. Organizing your pieces can also help you identify any additional components you may need.

3. Use Fasteners and Connectors

Utilize T-nuts and bolts designed specifically for T-slot extrusions:

- T-Nuts: Insert these into the T-slots to provide threaded holes for attaching other components.

- Brackets: Use L-brackets or T-brackets at corners for added stability.

When selecting fasteners, consider their strength ratings based on the load requirements of your project.

4. Assemble the Frame

Begin assembling your frame by connecting the pieces with the fasteners. Start with the main structure and gradually add additional components as needed. It's often helpful to loosely fit all components first before tightening them down completely; this allows for adjustments if necessary.

5. Check Alignment

As you assemble, regularly check that everything is level and square. Adjust as necessary before fully tightening all fasteners. Using a level on multiple sides can help ensure that your structure is perfectly aligned.

6. Final Touches

Once assembled, consider adding finishing touches such as end caps or surface treatments to enhance appearance and functionality. You might also want to paint or anodize the aluminum extrusion if aesthetics are important for your project.

Practical Applications of 8020 T-Slot Aluminum Extrusion

The versatility of 8020 T-slot aluminum extrusion allows it to be used in various applications:

- Workbenches: Create sturdy work surfaces tailored to your needs by adjusting height and size according to your workspace requirements.

- 3D Printer Frames: Build stable frames that can support heavy printers while allowing easy access for maintenance.

- Storage Solutions: Design custom shelving units or tool storage systems that maximize space efficiency in workshops or garages.

- Automated Machinery: Construct frameworks for robotics and automation projects that require precise alignment and stability.

- Display Stands: Create attractive display stands for trade shows or retail environments using lightweight yet sturdy materials that are easy to transport.

Design Ideas Using 8020 T-Slot Aluminum Extrusion

Here are some creative ideas to inspire your next project:

- Adjustable Shelving Units: Use vertical extrusions with horizontal shelves that can be adjusted at different heights based on storage needs.

- Mobile Carts: Construct carts on wheels that can be used in workshops or kitchens, allowing easy mobility while providing ample storage space.

- Custom Computer Desks: Design ergonomic desks with adjustable heights using linear actuators integrated into the frame structure.

- Garden Trellises: Build lightweight trellises using extrusions that can support climbing plants while being easy to relocate as needed.

Tips for Successful Projects

- Measure Twice, Cut Once: Always double-check measurements before cutting; this old adage holds true in woodworking and metalworking alike.

- Use CAD Software: For complex designs, consider using computer-aided design software to visualize your project before starting construction. This can help identify potential issues early on.

- Experiment with Designs: Don't hesitate to modify your design as you go; the modular nature of 8020 allows for easy adjustments without compromising structural integrity.

- Join Online Communities: Engage with online forums or social media groups dedicated to DIY projects using 8020 aluminum extrusion; sharing ideas can lead to innovative solutions and inspiration from others' experiences.

Maintenance Tips for Longevity

To ensure that your projects made from 8020 T-slot aluminum extrusion last as long as possible:

- Regularly inspect joints and connections for signs of wear or loosening.

- Clean surfaces periodically with mild soap and water; avoid harsh chemicals that could damage finishes.

- If exposed outdoors, consider applying protective coatings to enhance resistance against environmental factors such as moisture or UV rays.

Conclusion

Using 8020 T-slot aluminum extrusion for DIY projects opens up a world of possibilities due to its flexibility, strength, and ease of use. By following the steps outlined in this guide—from planning your project to assembling your structure—you can create functional and aesthetically pleasing designs tailored to your specific needs. Whether you're building something simple like a shelving unit or more complex machinery frames, understanding how to effectively utilize this material will enhance both your skills and satisfaction in DIY endeavors.

Frequently Asked Questions

1. What Is 8020 T-Slot Aluminum Extrusion?

- 8020 T-slot aluminum extrusion is a modular framing system made from aluminum profiles featuring T-shaped grooves that allow easy assembly using various connectors and fasteners.

2. What Are Common Uses for 8020 Aluminum?

- It is commonly used in building workbenches, custom machinery frames, shelving units, enclosures, furniture, display stands, mobile carts, garden trellises, and more.

3. How Do I Cut 8020 Aluminum Extrusion?

- You can cut it using a miter saw or band saw equipped with appropriate blades designed for cutting metal; ensure accurate measurements before cutting.

4. What Fasteners Do I Need?

- You will typically need T-nuts and bolts specifically designed for T-slot systems as well as brackets for added stability at joints; always choose fasteners rated appropriately for your project's load requirements.

5. Can I Modify My Design After Assembly?

- Yes! One of the key advantages of using 8020 aluminum is its modular nature, allowing you to easily modify or expand your design as needed without significant effort or rework required on existing components.