Content Menu

● Introduction to Aluminum Extrusion

● The Manufacturing Process

● Applications and Industries

● Choosing the Right Local Provider

● Quality Control and Standards

● Conclusion

● Frequently Asked Questions

Introduction to Aluminum Extrusion

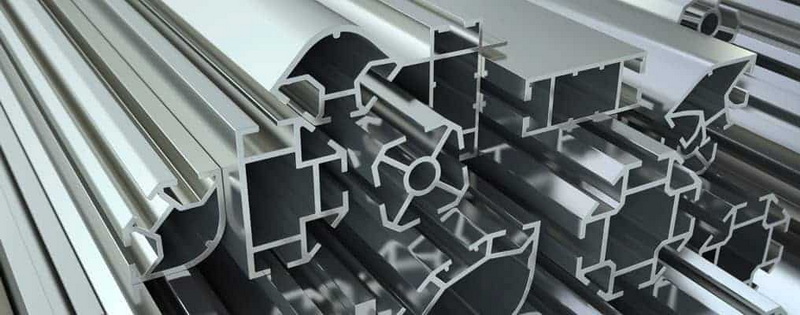

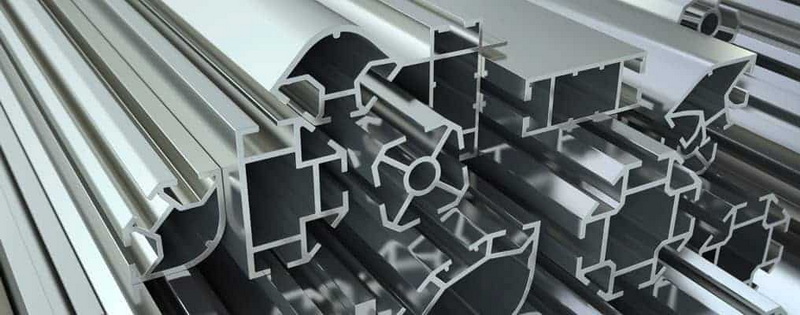

Aluminum extrusion is a sophisticated manufacturing process that has revolutionized modern industrial production. This versatile technique involves forcing aluminum alloy through a die to create objects with specific cross-sectional profiles, enabling the production of complex shapes and designs that serve countless applications across various industries. When searching for "Aluminum Extrusion Near Me," it's essential to understand that local manufacturers can offer numerous advantages, including faster turnaround times, reduced shipping costs, and the ability to maintain close communication throughout the production process.

The Manufacturing Process

The manufacturing process begins with heating aluminum billets to temperatures between 800°F and 925°F (427°C to 496°C). At these temperatures, the aluminum becomes malleable but not molten, making it perfect for extrusion. The heated billet is then placed in a container and forced through a die using a hydraulic ram under extreme pressure. This process can create both solid and hollow profiles, depending on the die design and intended application. Local manufacturers typically offer both standard and custom profiles, allowing businesses to obtain exactly what they need for their specific applications.

Applications and Industries

Aluminum extrusions find applications across numerous industries, making them an integral part of modern manufacturing. In the construction sector, they're used for window frames, door frames, and structural components. The automotive industry utilizes aluminum extrusions for lightweight vehicle components, helping to improve fuel efficiency while maintaining structural integrity. In the electronics industry, these profiles are essential for creating heat sinks and protective housings. The renewable energy sector employs aluminum extrusions in solar panel frames and mounting systems, while the aerospace industry relies on them for various structural components.

Choosing the Right Local Provider

When searching for "Aluminum Extrusion Near Me," several factors should influence your decision. First, consider the provider's technical capabilities, including their press sizes and maximum profile dimensions. Look for manufacturers who offer comprehensive services, from design assistance to finishing options like anodizing or powder coating. Quality certifications, such as ISO 9001:2015, indicate a commitment to consistent quality and professional standards. Additionally, evaluate their experience with your specific industry and their ability to meet your volume requirements, whether you need prototype quantities or high-volume production runs.

Quality Control and Standards

Professional aluminum extrusion facilities maintain rigorous quality control processes throughout production. This includes regular testing of material properties, dimensional accuracy, and surface finish quality. Modern facilities employ advanced measurement tools and testing equipment to ensure every piece meets specifications. When working with a local provider, you can often visit their facility to observe their quality control processes firsthand and discuss any specific requirements for your project.

Conclusion

Finding the right aluminum extrusion provider near you can significantly impact your project's success. Local manufacturers offer advantages in terms of communication, lead times, and collaborative problem-solving. By understanding the manufacturing process, applications, and quality considerations, you can make an informed decision when selecting a provider for your aluminum extrusion needs.

Frequently Asked Questions

Q1: What are the main advantages of working with a local aluminum extrusion provider?

A: Local providers offer faster turnaround times, reduced shipping costs, easier communication, and the ability to visit the facility for quality assurance.

Q2: What industries commonly use aluminum extrusions?

A: Key industries include construction, automotive, electronics, renewable energy, aerospace, and general manufacturing.

Q3: What should I look for in an aluminum extrusion manufacturer?

A: Look for ISO certification, technical capabilities, experience in your industry, comprehensive services, and quality control processes.

Q4: How long does the aluminum extrusion process typically take?

A: The actual extrusion process is relatively quick, but lead times can vary from 2-6 weeks depending on complexity, quantity, and finishing requirements.

Q5: What types of finishing options are available for aluminum extrusions?

A: Common finishing options include anodizing, powder coating, painting, brushing, and mechanical finishing techniques.

This article provides a comprehensive overview of aluminum extrusion services while incorporating the target keyword naturally throughout the text. The inclusion of relevant images and videos helps illustrate key concepts and processes, making the content more engaging and informative for readers.