Content Menu

● Introduction

● Understanding T-Slot Aluminum Extrusions

>> Key Features of T-Slot Aluminum Extrusions

● Benefits of Using T-Slot Aluminum Extrusions

>> Easy Assembly and Disassembly

>> Multi-Functional Applications

>> Cost-Effectiveness

● How to Choose the Right T-Slot Aluminum Extrusion

>> Determine Your Project Requirements

>> Select the Appropriate Profile Size

>> Consider the Slot Size

>> Evaluate the Finish

>> Assess Available Accessories

● Common Applications of T-Slot Aluminum Extrusions

● Conclusion

● Frequently Asked Questions

>> 1. What are the advantages of using T-slot aluminum extrusions?

>> 2. How do I determine the right profile size for my project?

>> 3. Can I customize T-slot aluminum extrusions for my specific needs?

>> 4. What types of finishes are available for T-slot aluminum extrusions?

>> 5. Where can I find T-slot aluminum extrusions near me?

Introduction

T-slot aluminum extrusions have become increasingly popular in various industries due to their versatility, strength, and ease of assembly. Whether you are building a custom workstation, a machine frame, or a display stand, understanding how to choose the right T-slot aluminum extrusion for your needs is crucial. This article will guide you through the essential factors to consider when selecting T-slot aluminum extrusions, ensuring that you make an informed decision that meets your project requirements.

Understanding T-Slot Aluminum Extrusions

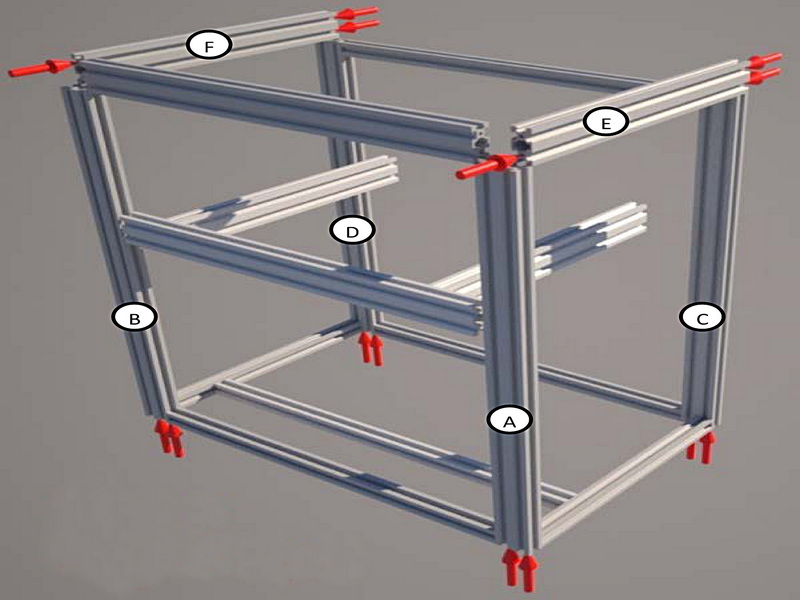

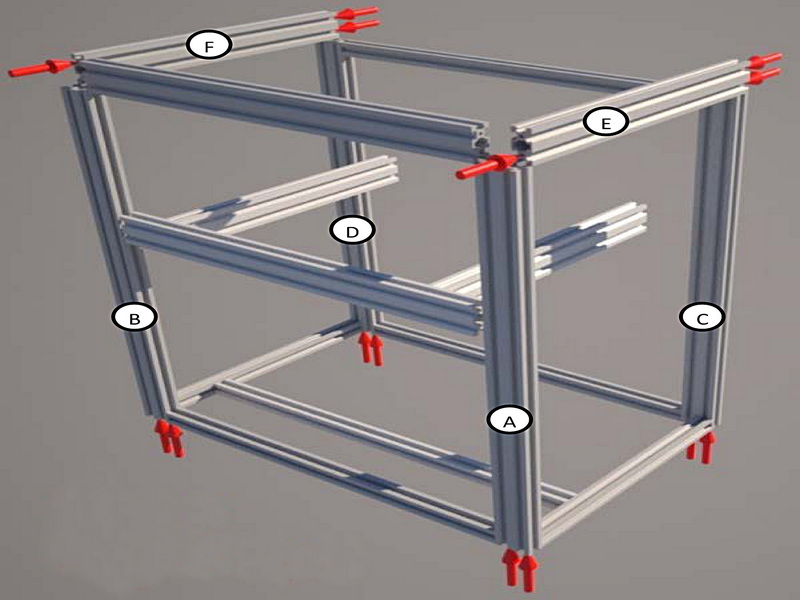

T-slot aluminum extrusions are aluminum profiles with a unique slot design that allows for easy assembly and modification. The T-slot design enables users to connect multiple pieces together using various fasteners and accessories, making it an ideal choice for modular construction. These extrusions are lightweight yet strong, making them suitable for a wide range of applications.

Key Features of T-Slot Aluminum Extrusions

- Lightweight and Durable: Aluminum is known for its lightweight properties, which makes it easy to handle and transport. Despite its lightness, aluminum is also incredibly strong and resistant to corrosion, ensuring longevity in various environments.

- Versatile Design: The modular nature of T-slot aluminum extrusions allows for endless design possibilities. You can create anything from simple frames to complex structures, adapting your design as needed.

- Ease of Assembly: One of the most significant advantages of T-slot aluminum extrusions is their ease of assembly. With the right connectors and tools, you can quickly put together or disassemble your structure without specialized skills.

Benefits of Using T-Slot Aluminum Extrusions

Easy Assembly and Disassembly

One of the standout features of T-slot aluminum extrusions is their straightforward assembly process. You can easily connect different pieces using T-nuts and bolts, allowing for quick modifications or disassembly when necessary. This flexibility is particularly beneficial for projects that may require adjustments over time.

Multi-Functional Applications

T-slot aluminum extrusions are used across various industries, including manufacturing, robotics, and construction. Their adaptability makes them suitable for creating machine frames, workstations, safety barriers, and even custom display stands. The ability to customize your design means you can tailor your project to meet specific needs.

Cost-Effectiveness

When compared to traditional materials like steel or wood, T-slot aluminum extrusions can be more cost-effective in the long run. Their lightweight nature reduces shipping costs, and the ease of assembly minimizes labor expenses. Additionally, the durability of aluminum means fewer replacements and repairs over time.

How to Choose the Right T-Slot Aluminum Extrusion

When selecting the right T-slot aluminum extrusion for your project, consider the following factors:

Determine Your Project Requirements

Before diving into the selection process, clearly define your project requirements. Consider the following questions:

- What is the intended use of the structure?

- What load will it need to support?

- Will it be exposed to harsh environmental conditions?

Understanding these requirements will help you narrow down your options.

Select the Appropriate Profile Size

T-slot aluminum extrusions come in various sizes and shapes. The profile size you choose will depend on the load requirements and the overall dimensions of your project. Larger profiles can support heavier loads, while smaller profiles are suitable for lighter applications.

Consider the Slot Size

The slot size of the T-slot aluminum extrusion is another critical factor. The slot size determines the type of fasteners and accessories you can use. Ensure that the slot size is compatible with the connectors and components you plan to incorporate into your design.

Evaluate the Finish

Aluminum extrusions can come in various finishes, including anodized, powder-coated, or mill finish. Anodized finishes provide additional corrosion resistance and a more polished appearance, while powder-coated finishes offer a wide range of color options. Choose a finish that aligns with your aesthetic preferences and environmental needs.

Assess Available Accessories

T-slot aluminum extrusions are often used with a variety of accessories, such as brackets, connectors, and fasteners. When selecting your extrusion, consider the availability of compatible accessories that will enhance the functionality of your structure.

Common Applications of T-Slot Aluminum Extrusions

T-slot aluminum extrusions are incredibly versatile and can be used in numerous applications, including:

- Industrial Equipment Frames: Many manufacturers use T-slot aluminum extrusions to create frames for machinery and equipment. Their strength and modularity allow for easy adjustments and repairs.

- Workstations: Custom workstations can be built using T-slot aluminum extrusions, providing a tailored solution for specific tasks. These workstations can be easily modified as needs change.

- Robotics Support Structures: In the robotics industry, T-slot aluminum extrusions are often used to create support structures for robotic arms and other components. Their lightweight nature helps improve the overall efficiency of robotic systems.

Conclusion

Choosing the right T-slot aluminum extrusion for your needs involves careful consideration of various factors, including project requirements, profile size, slot size, finish, and available accessories. By understanding these elements, you can make an informed decision that will lead to a successful project. T-slot aluminum extrusions offer a flexible, durable, and cost-effective solution for a wide range of applications, making them an excellent choice for both DIY enthusiasts and professionals alike.

Frequently Asked Questions

1. What are the advantages of using T-slot aluminum extrusions?

T-slot aluminum extrusions are lightweight, durable, easy to assemble, and versatile, making them suitable for various applications across different industries.

2. How do I determine the right profile size for my project?

Consider the load requirements and overall dimensions of your project. Larger profiles can support heavier loads, while smaller profiles are suitable for lighter applications.

3. Can I customize T-slot aluminum extrusions for my specific needs?

Yes, T-slot aluminum extrusions are highly customizable, allowing you to create structures tailored to your specific requirements.

4. What types of finishes are available for T-slot aluminum extrusions?

Common finishes include anodized, powder-coated, and mill finish. Each finish offers different aesthetic and protective qualities.

5. Where can I find T-slot aluminum extrusions near me?

You can find T-slot aluminum extrusions at local hardware stores, specialized suppliers, or online retailers. Searching for "t-slot aluminum extrusion near me" can help you locate nearby options.