Content Menu

● Understanding PVC Pipe Extrusion Lines

● The Role of PVC in Pipe Extrusion Lines

● Key Factors to Consider When Choosing a Supplier

>> 1. Production Requirements

>> 2. Quality of Equipment

>> 3. Supplier Reputation

>> 4. After-Sales Support

>> 5. Cost Considerations

● Evaluating Potential Suppliers

● Choosing Between Twin-Screw vs Single-Screw Extruders

>> Benefits of Twin Screw Extrusion for PVC Pipe Production

>> When to Use Single Screw Extruders in PVC Pipe Manufacturing

● Optimizing the Extrusion Process for PVC Pipe Manufacturing

● Ensuring Pipe Strength and Durability Through Precision Extrusion

● Advancements in Extrusion Technology for Higher Quality PVC Pipes

● Sustainability Trends in PVC Pipe Production

● Conclusion

● FAQ

>> 1. What types of PVC pipes can be produced using an extrusion line?

>> 2. How do I determine the right output capacity for my needs?

>> 3. What certifications should I look for in a PVC pipe extrusion line?

>> 4. Are there specific technological features I should prioritize?

>> 5. How important is after-sales support when choosing a supplier?

● Citations:

Choosing the right PVC pipe extrusion line supplier in China is crucial for manufacturers aiming to produce high-quality pipes efficiently and cost-effectively. With the increasing demand for PVC pipes across various industries, selecting a reliable supplier can significantly impact production quality, operational efficiency, and overall profitability. This comprehensive guide explores essential factors to consider when selecting a PVC pipe extrusion line supplier in China.

Understanding PVC Pipe Extrusion Lines

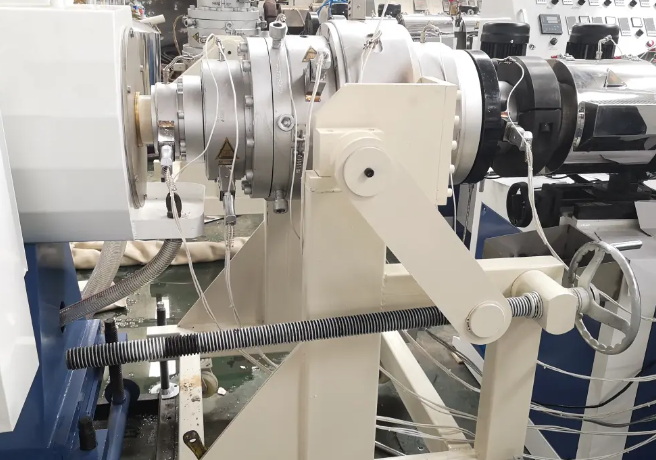

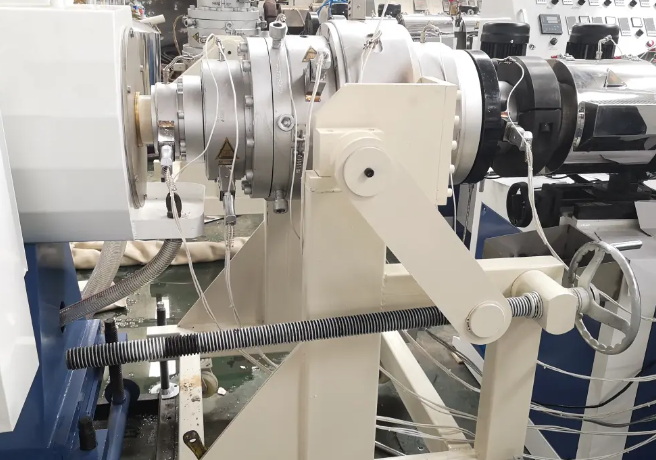

PVC pipe extrusion lines are automated systems designed to convert raw plastic materials into continuous pipe profiles. The process involves melting, shaping, cooling, and cutting the material into pipes of various sizes and thicknesses. These pipes are widely used in plumbing, irrigation, electrical installations, and gas transportation.

The Role of PVC in Pipe Extrusion Lines

PVC is dominant in pipe extrusion lines due to its exceptional properties, including durability, resistance to corrosion and chemicals, low cost, and ease of installation. These characteristics make PVC ideal for various applications:

- Residential plumbing

- Sewage systems

- Agricultural irrigation

- Industrial fluid handling

Additionally, PVC's versatility allows for producing pipes with varying degrees of flexibility, thickness, and strength, catering to specific application requirements. In the context of extrusion lines, PVC's thermoplastic nature facilitates efficient melting and shaping processes, contributing to high productivity and sustainability in manufacturing operations.

Key Factors to Consider When Choosing a Supplier

1. Production Requirements

Before selecting a supplier, it is essential to define your production requirements clearly. Consider the following aspects:

- Pipe Size Range: Determine the diameters and lengths of pipes you intend to produce.

- Output Capacity: Assess the required output capacity per hour or day.

- Material Specifications: Identify the types of PVC material you will use and any specific quality standards that must be met.

- Regulatory Compliance: Ensure that the supplier's equipment complies with relevant industry regulations and standards.

2. Quality of Equipment

The quality of the extrusion line directly affects the final product's quality. When evaluating suppliers, consider:

- Material Quality: Ensure that the supplier uses high-quality materials for their machines that can withstand intensive production processes.

- Technological Features: Look for modern extrusion lines equipped with advanced technologies such as PLC control systems, touch-screen interfaces, and automation features that enhance precision and reduce human error.

- Durability and Maintenance: Choose suppliers that offer robust machinery with easy maintenance options to minimize downtime.

3. Supplier Reputation

Researching potential suppliers' reputations is vital. Consider:

- Experience: Look for suppliers with a proven track record in manufacturing PVC pipe extrusion lines. Experienced suppliers are more likely to provide reliable equipment and support.

- Customer Reviews: Check online reviews and testimonials from previous customers to gauge satisfaction levels and reliability.

- Certifications: Verify that the supplier's products meet international quality standards such as ISO or CE certifications.

4. After-Sales Support

After-sales support is crucial for ensuring smooth operations after purchasing equipment. Consider:

- Technical Support: Ensure that the supplier offers comprehensive technical support, including installation assistance, training programs for operators, and prompt responses to inquiries.

- Spare Parts Availability: Choose suppliers that provide easy access to spare parts to minimize downtime during repairs or maintenance.

5. Cost Considerations

While price shouldn't be the only factor in your decision-making process, it is essential to assess:

- Total Cost of Ownership: Consider not just the initial purchase price but also operational costs such as energy consumption, maintenance expenses, and potential downtime costs.

- Financing Options: Some suppliers may offer financing options or flexible payment terms that can ease your cash flow management.

Evaluating Potential Suppliers

Once you have defined your criteria, start evaluating potential suppliers based on the following steps:

1. Request Quotes: Contact multiple suppliers to request detailed quotes based on your specifications.

2. Compare Features: Create a comparison chart outlining each supplier's offerings regarding technology, capacity, support services, and pricing.

3. Visit Facilities: If possible, visit the manufacturing facilities of shortlisted suppliers to inspect their production processes and quality control measures firsthand.

4. Ask for References: Request references from previous clients who have purchased similar equipment from the supplier.

5. Negotiate Terms: Once you have identified a suitable supplier, negotiate terms of sale including warranty periods, service agreements, and delivery timelines.

Choosing Between Twin-Screw vs Single-Screw Extruders

When selecting an extrusion line supplier in China for PVC pipe production, one critical decision involves choosing between twin-screw and single-screw extruders:

Benefits of Twin Screw Extrusion for PVC Pipe Production

Twin screw extruders offer several advantages due to their design and operational characteristics:

- Superior mixing capabilities ensure a more uniform melt.

- Ability to process a broader range of materials without compromising product quality.

- Enhanced control over processing conditions contributes to efficiency.

When to Use Single Screw Extruders in PVC Pipe Manufacturing

Single screw extruders are best suited when simplicity and cost-effectiveness are priorities:

- They excel in producing homogeneous materials like rigid PVC.

- Require less maintenance and operational know-how.

- Present a compelling choice for operations prioritizing energy efficiency.

Optimizing the Extrusion Process for PVC Pipe Manufacturing

To elevate the performance of PVC pipe extrusion lines:

1. Focus on enhancing production line speed.

2. Increase material throughput while minimizing waste.

3. Implement real-time monitoring systems to track performance metrics.

Ensuring Pipe Strength and Durability Through Precision Extrusion

The strength and durability of PVC pipes are significantly influenced by precision during extrusion. Key parameters include:

- Optimal wall thickness

- Uniformity in dimensions

- Consistent material flow rates

Advancements in Extrusion Technology for Higher Quality PVC Pipes

The PVC pipe manufacturing industry continually benefits from technological advancements that enhance product quality:

1. Computer-Aided Design (CAD) allows precise design of dies optimizing flow channels.

2. Real-Time Monitoring Systems enable automatic adjustments during production.

3. Innovations in material science lead to easier processing formulations resulting in superior performance characteristics.

Sustainability Trends in PVC Pipe Production

As environmental concerns grow globally, manufacturers are increasingly focusing on sustainability within their production processes:

1. Implementing recycling technologies minimizes waste by reusing scraps.

2. Developing eco-friendly formulations reduces carbon footprints during production.

3. Utilizing renewable energy sources within manufacturing facilities enhances sustainability efforts.

Conclusion

Selecting the right PVC pipe extrusion line supplier in China involves careful consideration of various factors including production requirements, equipment quality, supplier reputation, after-sales support, cost considerations, and technological advancements. By thoroughly evaluating potential suppliers based on these criteria, manufacturers can make informed decisions that enhance their production capabilities while ensuring high-quality output tailored to market demands.

FAQ

1. What types of PVC pipes can be produced using an extrusion line?

PVC pipe extrusion lines can produce various types of pipes used for water supply, drainage systems, electrical conduits, and gas transportation.

2. How do I determine the right output capacity for my needs?

To determine output capacity, consider your production goals including daily or hourly pipe requirements based on market demand or project specifications.

3. What certifications should I look for in a PVC pipe extrusion line?

Look for certifications such as ISO 9001 for quality management systems and CE marking indicating compliance with European safety standards.

4. Are there specific technological features I should prioritize?

Yes! Focus on features like PLC control systems for automation, energy-efficient motors to reduce operational costs, and advanced calibration techniques for consistent product quality.

5. How important is after-sales support when choosing a supplier?

After-sales support is crucial as it ensures you have access to technical assistance, spare parts availability, and operator training which can significantly reduce downtime during operation.

Citations:

[1] https://jieyatwinscrew.com/blog/pvc-pipe-extruder-machine/

[2] https://www.bausano.com/en/press-and-news/pvc-pipe-extrusion

[3] https://www.ifanplumbing.com/info/manufacturing-processes-and-emerging-technolog-99590226.html

[4] https://www.qenos.com/internet/home.nsf/web/RHAT-96N3WM

[5] https://www.bausano.com/en/applications/extrusion-lines-for-pipes

[6] https://www.ctube-gr.com/news/advancements-in-pvc-conduit-manufacturing-technology.html

[7] https://www.apollopipes.com/blog/pvc-pipes-advancement

[8] https://www.elastron.com/en/12-extrusion-defects-and-troubleshooting-elastron-tpe

[9] https://www.battenfeld-cincinnati.com/applications/pipe

[10] https://www.expertmarketresearch.com/reports/pvc-pipes-market