Content Menu

● Introduction to Extrusion Blow Molding

>> Process Overview

● Key Factors to Consider When Buying an Automatic Extrusion Blow Molding Machine

>> 1. Production Capacity

>> 2. Machine Size and Type

>> 3. Material Compatibility

>> 4. Automation Level

>> 5. Energy Efficiency and Cost

>> 6. After-Sales Support

>> 7. Budget and Total Cost of Ownership

● Advanced Features in Modern Machines

● Industry Trends and Future Developments

● Case Studies: Successful Implementations

● Conclusion

● Frequently Asked Questions

>> 1. What are the main types of blow molding machines?

>> 2. How do I choose the right blow molding machine for my business?

>> 3. What are the benefits of buying an automatic extrusion blow molding machine?

>> 4. How important is after-sales support when buying a blow molding machine?

>> 5. What factors affect the price of an extrusion blow molding machine?

● Citations:

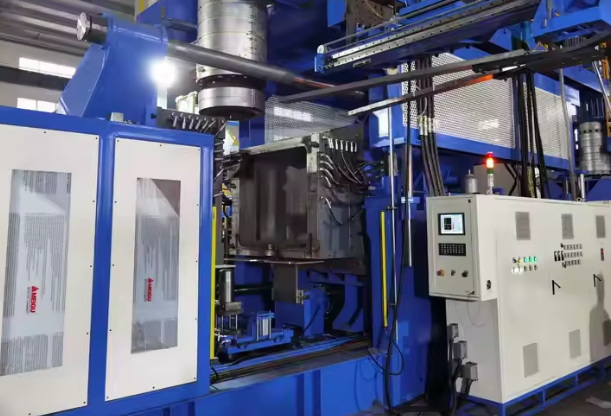

Choosing the right automatic extrusion blow molding machine is crucial for manufacturers seeking to optimize their production of plastic containers, such as bottles, jerry cans, and barrels. This article will guide you through the key factors to consider when selecting an automatic extrusion blow molding machine, ensuring that your investment aligns with your production needs and enhances efficiency.

Introduction to Extrusion Blow Molding

Extrusion blow molding (EBM) is a widely used technique for producing hollow plastic products. It involves extruding a hot tube of plastic material, known as a parison, into a mold where it is blown into shape using compressed air. EBM is ideal for manufacturing medium to large containers, such as HDPE bottles and fuel tanks.

Process Overview

The process of extrusion blow molding involves several key steps:

1. Extrusion: The plastic material is melted and formed into a parison.

2. Molding: The parison is placed into a mold and blown into shape.

3. Cooling: The plastic cools and solidifies, maintaining its shape.

4. Ejection: The finished product is ejected from the mold.

Key Factors to Consider When Buying an Automatic Extrusion Blow Molding Machine

When you decide to buy an automatic extrusion blow molding machine, several factors must be considered to ensure that the machine meets your production requirements and enhances efficiency.

1. Production Capacity

The production capacity of the machine is critical. It should be slightly higher than your current demand to accommodate future growth. For example, if you need to produce 1000 bottles per hour, consider a machine capable of producing at least 1250 bottles per hour. This buffer ensures that you can meet increased demand without overloading the machine, which could lead to reduced lifespan or decreased product quality.

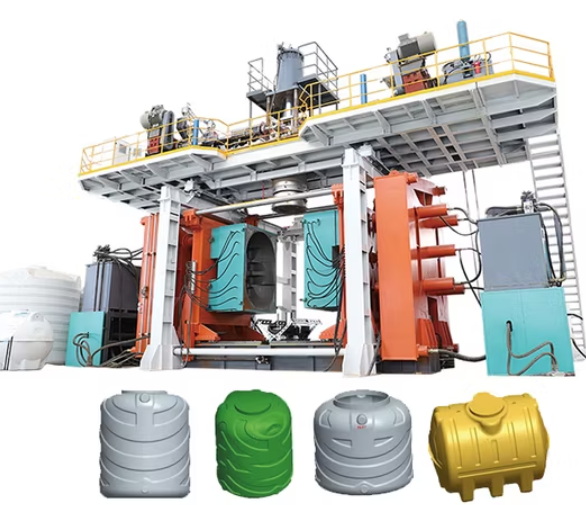

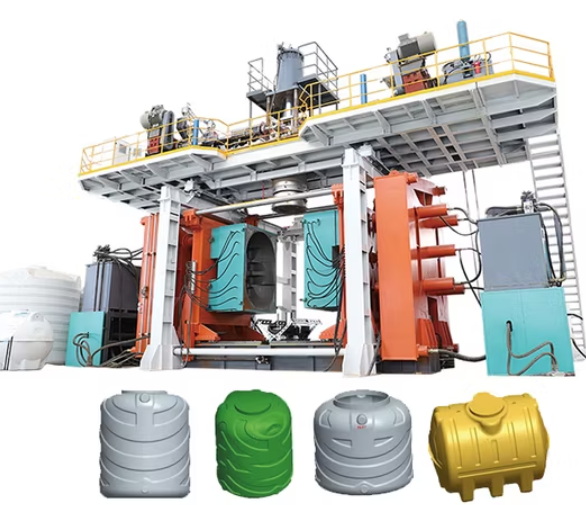

2. Machine Size and Type

The size of the machine determines the size of the mold and, consequently, the size of the product. Ensure the machine is compatible with the size and type of containers you plan to produce. For instance, if you need to produce large jerry cans, you'll require a larger machine. Additionally, consider the number of cavities the machine has, as this affects how many products can be produced simultaneously.

3. Material Compatibility

Ensure the machine is compatible with the type of plastic material you plan to use, such as HDPE, PVC, or PET. Different materials may require specific machine settings or components. For example, PET typically requires a different setup than HDPE due to its distinct thermal properties.

4. Automation Level

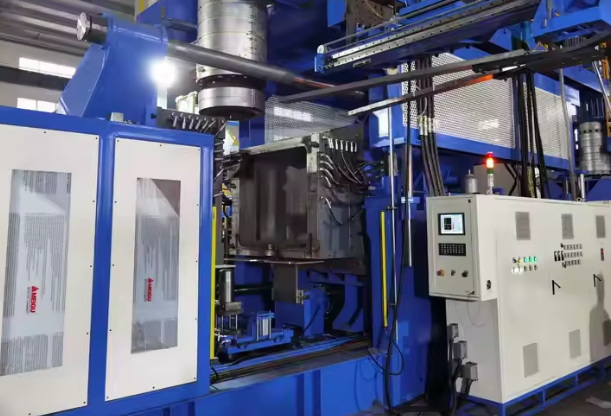

Fully automatic machines offer higher efficiency and reduced labor costs. They are equipped with advanced features like touch-screen controls and real-time monitoring, which enhance productivity and product quality. The choice between semi-automatic and fully automatic machines depends on your production scale and labor costs. If labor costs are high, a fully automated system is more beneficial.

5. Energy Efficiency and Cost

Consider the energy consumption of the machine, as it affects both operational costs and environmental impact. Modern machines often feature energy-saving technologies, such as servo-driven hydraulic systems, which can significantly reduce power consumption. Efficient cooling and heating systems also play a crucial role in lowering operational costs.

6. After-Sales Support

A reliable manufacturer offering comprehensive after-sales support is essential for minimizing downtime and ensuring long-term efficiency. Look for manufacturers with a proven track record of responsive service and readily available spare parts.

7. Budget and Total Cost of Ownership

While the initial purchase price is important, also consider the total cost of ownership, including maintenance costs, energy consumption, and potential downtime. A machine with a higher upfront cost might offer long-term savings through reduced operational expenses.

Advanced Features in Modern Machines

Modern automatic extrusion blow molding machines often come with advanced features that enhance efficiency and product quality. These include:

- Real-Time Monitoring Systems: Allow operators to track production in real-time, enabling quick adjustments to optimize output.

- Predictive Maintenance: Uses data analytics to predict when maintenance is needed, reducing unexpected downtime.

- IoT Integration: Enables remote monitoring and control, allowing for more flexible management of production processes.

These features not only improve production efficiency but also contribute to better product consistency and reduced waste.

Industry Trends and Future Developments

The blow molding industry is evolving rapidly, with a focus on sustainability and technological advancements. Manufacturers are increasingly looking for machines that can handle eco-friendly materials, such as recycled HDPE, and integrate Industry 4.0 technologies like AI-powered defect detection and IoT-enabled diagnostics. These advancements not only enhance efficiency but also support environmental sustainability.

Case Studies: Successful Implementations

Several companies have successfully integrated automatic extrusion blow molding machines into their production lines, achieving significant improvements in efficiency and product quality. For example, a leading bottle manufacturer increased its production capacity by 30% after switching to a fully automated EBM machine, while also reducing energy consumption by 20%.

Conclusion

Choosing the right automatic extrusion blow molding machine requires careful consideration of several factors, including production capacity, machine size, material compatibility, automation level, energy efficiency, after-sales support, and budget. By evaluating these aspects, manufacturers can ensure that their investment aligns with their production needs, enhancing efficiency and contributing to long-term success.

Frequently Asked Questions

1. What are the main types of blow molding machines?

- Extrusion Blow Molding (EBM): Ideal for medium to large containers.

- Injection Blow Molding (IBM): Used for small, precision products.

- Stretch Blow Molding (SBM): Commonly used for PET bottles in the beverage industry.

2. How do I choose the right blow molding machine for my business?

- Consider factors such as production volume, product design, material compatibility, and budget.

3. What are the benefits of buying an automatic extrusion blow molding machine?

- Automatic machines offer higher efficiency, reduced labor costs, and improved product quality.

4. How important is after-sales support when buying a blow molding machine?

- After-sales support is crucial for minimizing downtime and ensuring long-term efficiency.

5. What factors affect the price of an extrusion blow molding machine?

- Factors include production capacity, automation level, and features such as energy-saving technologies.

Citations:

[1] https://www.youlizn.com/news/blow-molding-machine-buying-guide.html

[2] https://www.changshengda.com/news/industry-news/high-speed-revolution-the-gamechanging-impact-of-the-automatic-blow-molding-machine.html

[3] https://www.tongdamachine.net/choose-right-extrusion-blow-molding-machine/

[4] https://www.watertankmachine.com/12-Things-to-Consider-Before-Buying-a-Blow-Molding-Machine-id45529147.html

[5] https://www.tech-long.com/a-how-to-choose-blow-molding-machine.html

[6] https://www.xz-machinery.com/how-to-choose-the-right-ibc-blow-molding-machine-key-buying-factors/

[7] https://www.linkedin.com/pulse/how-solve-common-problems-blow-molding-machines-products-ray-wang-dxlxc

[8] https://www.youlizn.com/news/fully-automatic-electric-blow-molding-machine-buying-guide.html

[9] https://wmpowerjet.en.made-in-china.com/product/VFAtEryuqiGR/China-Automatic-Plastic-200ml-2L-4L-5L-Agriculture-PVC-PE-Bottle-Barrel-Extrusion-Blow-Molding-Machines-Price.html

[10] https://news.technepackaging.com/en/blow-molding-key-aspects

[11] https://www.tech-long.com/t-how-to-determine-best-blow-molding-machine-buying-guide.html

[12] http://jspakmachine.com/automatic-extrusion-blow-molding-machine/

[13] https://cmppin.com/blog/how-to-select-a-blow-moulding-machine/

[14] https://gsblowing.com/blow-molding-machine-buying-guide/

[15] https://www.alibaba.com/product-detail/Automatic-Extrusion-Blow-Molding-Machine_62218714183.html

[16] https://www.custom-pak.com/avoid-these-common-blow-molding-design-mistakes/

[17] https://www.jwellextrusions.com/matters-needing-attention-in-purchasing-blow-molding-machine-and-factors-affecting-its-life.html

[18] https://www.youlizn.com/blow-molding-machines/yl-25l-plastic-extrusion-automatic-blow-molding-machine.html

[19] http://en.zhongyagroup.com/product/52.html

[20] https://www.moldingmachinetepai.com/productstags/blow-molding-machine.html