Content Menu

● Introduction

● Understanding Aluminum Extrusion Profiles

>> T-Slot Aluminum Extrusions

>> Square Tubes and Angle Profiles

● Benefits of Aluminum Extrusion Profiles

>> Versatility

>> Ease of Assembly

>> Customization Options

● Key Components and Accessories

>> Connectors

>> Fasteners

>> Brackets

>> End Caps

● Real-World Applications

>> Manufacturing

>> Robotics

>> Construction

>> DIY Projects

● Conclusion

● Related Questions

>> 1. What factors should I consider when selecting aluminum extrusion profiles?

>> 2. How do I determine the right size of aluminum extrusion profile for my project?

>> 3. Can I use aluminum extrusion profiles for outdoor applications?

>> 4. What tools do I need to assemble aluminum extrusion profiles?

>> 5. Are there any limitations to using aluminum extrusion profiles?

Introduction

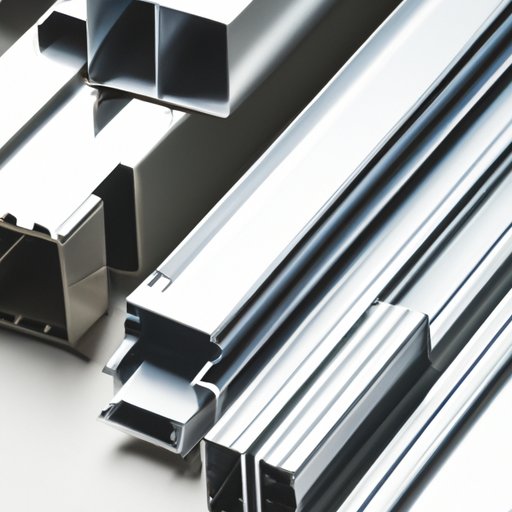

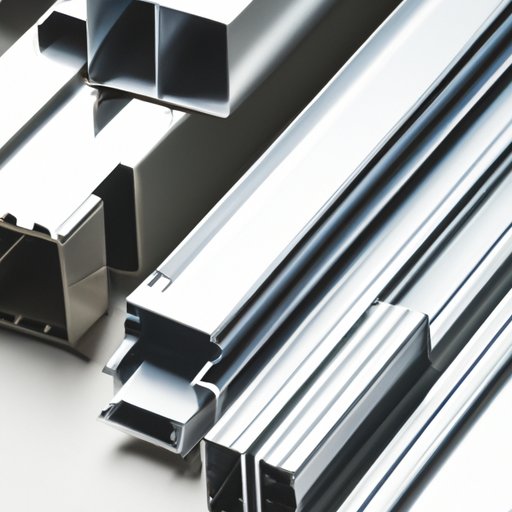

Aluminum extrusion is a manufacturing process that shapes aluminum alloy into a desired cross-sectional profile. This process is widely used in various industries due to its versatility, lightweight nature, and resistance to corrosion. Among the many types of aluminum extrusion products, aluminum extrusion profiles stand out as essential components in construction, manufacturing, and DIY projects. Choosing the right aluminum extrusion profiles for your needs can significantly impact the efficiency and effectiveness of your projects. This article will guide you through the process of selecting the right aluminum extrusion profiles, focusing on the various factors to consider, the benefits of using aluminum extrusion hardware, and practical applications.

Understanding Aluminum Extrusion Profiles

Aluminum extrusion profiles are created by forcing heated aluminum through a die, resulting in a specific shape. These profiles can be customized to meet the unique requirements of different applications. The most common types of aluminum extrusion profiles include T-slot profiles, square tubes, and angle profiles. Each type has its own set of characteristics and advantages, making it crucial to understand their differences when selecting the right profile for your project.

T-Slot Aluminum Extrusions

T-slot aluminum extrusions are particularly popular in the construction of frames and structures. The T-slot design allows for easy assembly and disassembly, making it ideal for modular systems. These profiles come with grooves that accommodate various accessories, such as brackets, connectors, and fasteners, enabling users to create custom configurations with minimal effort.

Square Tubes and Angle Profiles

Square tubes and angle profiles are also widely used in various applications. Square tubes provide excellent structural integrity and are often used in load-bearing applications. Angle profiles, on the other hand, are ideal for creating corners and supports in structures. Understanding the specific characteristics of these profiles will help you make an informed decision based on your project requirements.

Benefits of Aluminum Extrusion Profiles

Versatility

One of the primary benefits of aluminum extrusion profiles is their versatility. They can be used in a wide range of applications, from industrial machinery to consumer products. The ability to customize profiles to meet specific needs makes aluminum extrusion hardware an attractive option for engineers and designers.

Ease of Assembly

Aluminum extrusion profiles are designed for easy assembly. The T-slot design, in particular, allows users to connect profiles without the need for complex tools or extensive knowledge of construction techniques. This ease of assembly can save time and reduce labor costs, making it an efficient choice for both professionals and DIY enthusiasts.

Customization Options

Another significant advantage of aluminum extrusion profiles is the wide range of customization options available. Manufacturers can create profiles in various shapes, sizes, and finishes to meet specific project requirements. This flexibility allows for innovative designs and solutions that can enhance the overall functionality of a project.

Key Components and Accessories

When working with aluminum extrusion profiles, it is essential to consider the various components and accessories that can enhance their functionality. These include connectors, fasteners, brackets, and end caps. Selecting the right accessories is crucial for ensuring the stability and durability of your structures.

Connectors

Connectors are used to join two or more aluminum extrusion profiles together. They come in various shapes and sizes, allowing for different angles and configurations. Choosing the right connectors will depend on the specific design and load requirements of your project.

Fasteners

Fasteners, such as screws and bolts, are essential for securing aluminum extrusion profiles and connectors. It is important to select fasteners that are compatible with the aluminum material to prevent corrosion and ensure a strong bond.

Brackets

Brackets provide additional support and stability to aluminum extrusion structures. They can be used to reinforce corners, attach profiles to walls, or create shelving systems. The right brackets can enhance the overall strength and functionality of your project.

End Caps

End caps are used to cover the open ends of aluminum extrusion profiles. They provide a finished look and can help prevent dirt and debris from entering the profile. Additionally, end caps can enhance safety by eliminating sharp edges.

Real-World Applications

Aluminum extrusion profiles are used in a variety of industries and applications. Here are some examples of how these profiles are utilized in real-world scenarios:

Manufacturing

In manufacturing, aluminum extrusion profiles are often used to create frames for machinery, conveyor systems, and workstations. Their lightweight nature and strength make them ideal for building structures that require mobility and flexibility.

Robotics

The robotics industry frequently employs aluminum extrusion profiles to construct robot frames and components. The modularity of T-slot profiles allows for easy adjustments and modifications, enabling engineers to design and build robots that meet specific performance criteria.

Construction

In construction, aluminum extrusion profiles are used for window frames, curtain walls, and structural supports. Their resistance to corrosion and lightweight properties make them an excellent choice for both residential and commercial buildings.

DIY Projects

For DIY enthusiasts, aluminum extrusion profiles offer endless possibilities for creating custom furniture, shelving units, and display cases. The ease of assembly and customization options make it simple for anyone to design and build their own projects.

Conclusion

Choosing the right aluminum extrusion profiles for your needs is a critical step in ensuring the success of your projects. By understanding the different types of profiles available, their benefits, and the key components and accessories, you can make informed decisions that will enhance the efficiency and effectiveness of your work. Whether you are involved in manufacturing, robotics, construction, or DIY projects, aluminum extrusion hardware offers versatile solutions that can meet a wide range of requirements.

Related Questions

1. What factors should I consider when selecting aluminum extrusion profiles?

When selecting aluminum extrusion profiles, consider factors such as the intended application, load requirements, ease of assembly, and available customization options.

2. How do I determine the right size of aluminum extrusion profile for my project?

To determine the right size, assess the load requirements and dimensions of your project. It is essential to choose a profile that can support the intended weight and fit within the available space.

3. Can I use aluminum extrusion profiles for outdoor applications?

Yes, aluminum extrusion profiles are suitable for outdoor applications due to their resistance to corrosion. However, it is advisable to choose profiles with protective coatings for added durability.

4. What tools do I need to assemble aluminum extrusion profiles?

Basic tools such as a saw, drill, and screwdriver are typically sufficient for assembling aluminum extrusion profiles. T-slot profiles often require minimal tools for assembly.

5. Are there any limitations to using aluminum extrusion profiles?

While aluminum extrusion profiles offer many advantages, they may not be suitable for applications requiring extreme strength or high-temperature resistance. It is essential to evaluate the specific requirements of your project before making a selection.