Content Menu

● Understanding Aluminum Extrusion Profiles

● Key Factors to Consider When Choosing Aluminum Extrusion Profile Manufacturers

>> 1. Experience and Expertise

>> 2. Manufacturing Capabilities

>> 3. Quality Control Measures

>> 4. Material Selection and Alloy Expertise

>> 5. Production Capacity and Lead Times

>> 6. Custom Extrusion Capabilities

>> 7. Value-Added Services

>> 8. Technology and Innovation

>> 9. Sustainability Practices

>> 10. Customer Service and Support

● The Selection Process

● Case Study: Successful Manufacturer Selection

● Conclusion

● Frequently Asked Questions

>> 1. What are the main advantages of using aluminum extrusion profiles?

>> 2. How long does the aluminum extrusion process typically take?

>> 3. What are the most common aluminum alloys used in extrusion profiles?

>> 4. How can I ensure the quality of aluminum extrusion profiles from a manufacturer?

>> 5. What are the environmental considerations when choosing an aluminum extrusion profile manufacturer?

● Citations:

Selecting the right aluminum extrusion profile manufacturer is a crucial decision that can significantly impact the success of your project. Whether you're in the construction, automotive, or aerospace industry, finding a reliable partner to produce high-quality aluminum extrusions is essential. This comprehensive guide will walk you through the key factors to consider when choosing an aluminum extrusion profile manufacturer, helping you make an informed decision that aligns with your project needs and goals.

Understanding Aluminum Extrusion Profiles

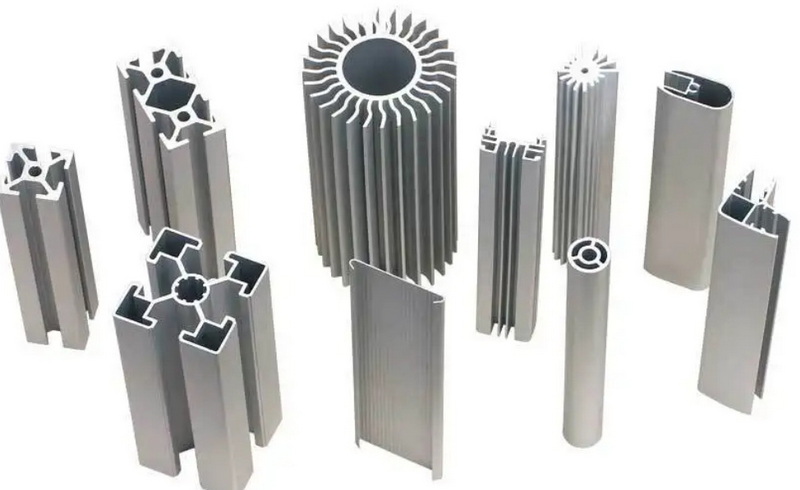

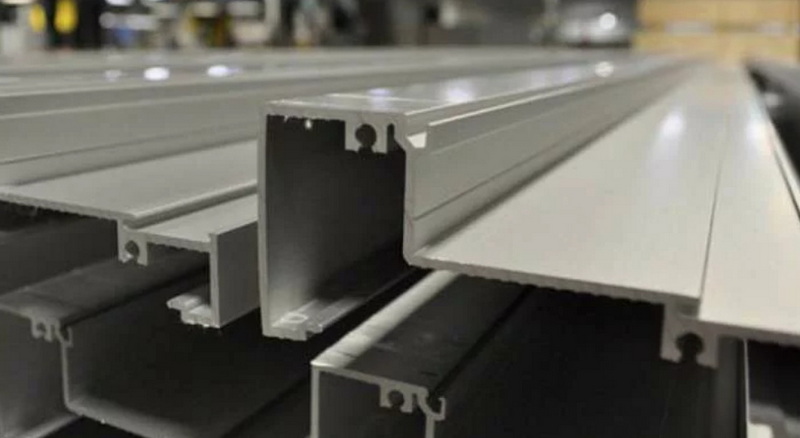

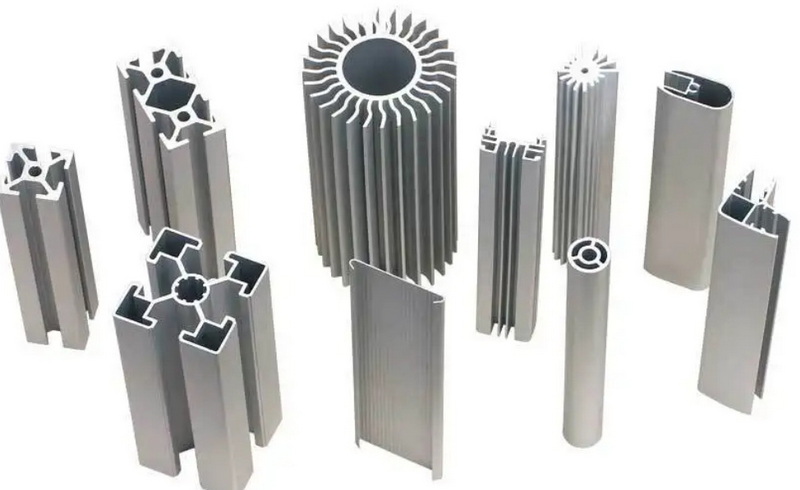

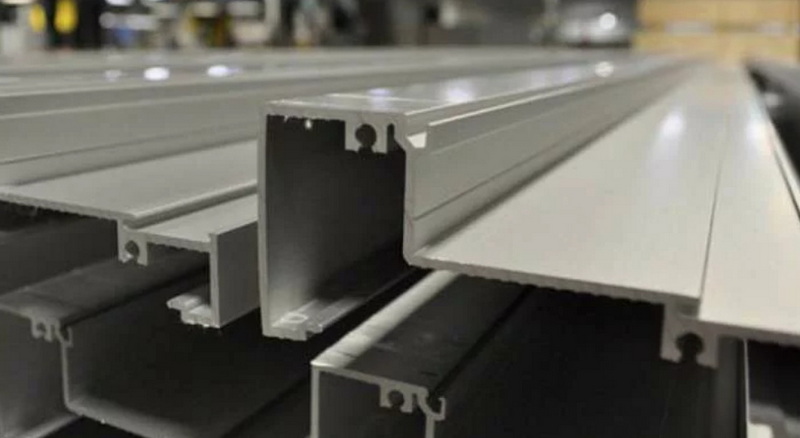

Before delving into the selection process, it's important to understand what aluminum extrusion profiles are and their applications. Aluminum extrusion is a manufacturing process where aluminum alloy material is forced through a die with a specific cross-sectional profile. The result is a long, straight piece of aluminum with a consistent cross-section.

Aluminum extrusion profiles are used in various industries due to their versatility, strength-to-weight ratio, and corrosion resistance. They are commonly found in:

- Construction (window frames, door frames, curtain walls)

- Automotive (body frames, heat sinks)

- Aerospace (aircraft components)

- Electronics (heat sinks, LED housings)

- Furniture (modular designs, framing)

Key Factors to Consider When Choosing Aluminum Extrusion Profile Manufacturers

1. Experience and Expertise

When selecting aluminum extrusion profile manufacturers, prioritize those with extensive experience in the industry. Look for companies that have been operating for several years and have a proven track record of delivering high-quality extruded products[1].

Consider the manufacturer's expertise in your specific industry or application. Different sectors may have unique requirements or regulations, and a manufacturer familiar with your industry will be better equipped to meet your needs[1].

2. Manufacturing Capabilities

Assess the production capabilities of potential aluminum extrusion profile manufacturers. A reliable manufacturer should have well-equipped facilities with modern machinery and technology[1]. The quality and precision of extruded profiles largely depend on the equipment used.

Inquire about the range of products the manufacturer can produce. Depending on your project requirements, you may need specific profile configurations. Ensure that the manufacturer can meet your design specifications[1].

3. Quality Control Measures

Quality control is critical in aluminum extrusion. Ask about the manufacturer's quality control procedures and certifications. A reputable manufacturer should perform quality checks at various stages of the extrusion process to ensure that the final products meet industry standards and your specifications[1].

Look for manufacturers who are ISO certified or have other relevant industry certifications. These certifications indicate that the company follows best practices and is committed to maintaining consistent product quality[1].

4. Material Selection and Alloy Expertise

When researching aluminum extrusion profile manufacturers, it's crucial to understand the importance of aluminum alloy selection and its compatibility with your project requirements. They should have access to a variety of alloys and be able to source materials from reputable suppliers[1].

5. Production Capacity and Lead Times

Consider the manufacturer's production capacity and typical lead times. This is particularly important if you have large volume requirements or tight project deadlines. A manufacturer with ample capacity can ensure timely delivery of your orders[2].

6. Custom Extrusion Capabilities

If your project requires custom extrusion profiles, ensure that the manufacturer has the capability to design and produce custom dies. Ask about their design process, die-making capabilities, and experience with custom extrusions[2].

7. Value-Added Services

Many aluminum extrusion profile manufacturers offer additional services that can add value to your project. These may include:

- Fabrication and machining

- Surface finishing (anodizing, powder coating, etc.)

- Assembly services

- Design assistance and engineering support

Consider which value-added services might benefit your project and look for manufacturers that offer them[4].

8. Technology and Innovation

The aluminum extrusion industry is constantly evolving with new technologies and processes. Choose a manufacturer that invests in the latest technology and demonstrates a commitment to innovation. This can lead to improved product quality, efficiency, and potentially cost savings for your project[5].

9. Sustainability Practices

With increasing focus on environmental responsibility, consider the sustainability practices of potential aluminum extrusion profile manufacturers. Look for companies that use recycled aluminum, implement energy-efficient processes, and have environmental certifications[5].

10. Customer Service and Support

Excellent customer service and technical support are crucial when working with aluminum extrusion profile manufacturers. Look for a company that is responsive to inquiries, provides clear communication, and offers technical assistance throughout your project[6].

The Selection Process

Now that we've covered the key factors to consider, let's outline a step-by-step process for selecting the right aluminum extrusion profile manufacturer:

1. Define Your Requirements: Clearly outline your project needs, including profile specifications, volume requirements, and any special considerations.

2. Research Potential Manufacturers: Use online resources, industry directories, and recommendations to create a list of potential aluminum extrusion profile manufacturers.

3. Initial Screening: Review the websites and capabilities of each manufacturer on your list. Eliminate those that don't meet your basic requirements.

4. Request Quotes and Information: Contact the remaining manufacturers to request quotes and detailed information about their capabilities, processes, and services.

5. Evaluate Responses: Compare the responses from different manufacturers, considering factors such as pricing, lead times, quality assurance, and value-added services.

6. Check References: Ask for and contact references from each manufacturer to get insights into their performance and reliability.

7. Site Visits: If possible, arrange site visits to the top contenders' facilities to see their operations firsthand.

8. Final Selection: Based on all the information gathered, select the aluminum extrusion profile manufacturer that best meets your needs and aligns with your project goals.

Case Study: Successful Manufacturer Selection

To illustrate the importance of careful manufacturer selection, let's look at a brief case study:

A leading automotive parts supplier needed a new aluminum extrusion profile manufacturer for a critical component in their latest electric vehicle design. They followed the selection process outlined above and ultimately chose a manufacturer that offered:

- Extensive experience in automotive extrusions

- Advanced quality control systems

- Custom die design capabilities

- Value-added services including precision machining and assembly

- A strong commitment to sustainability

As a result of this careful selection, the supplier was able to:

- Reduce lead times by 20%

- Improve part quality and consistency

- Decrease overall costs through efficient design and production

- Meet stringent environmental standards required by their automotive clients

This case demonstrates how choosing the right aluminum extrusion profile manufacturer can have a significant positive impact on a project's success.

Conclusion

Choosing the right aluminum extrusion profile manufacturer is a critical decision that can significantly impact the success of your project. By considering factors such as experience, manufacturing capabilities, quality control measures, and value-added services, you can select a partner that will meet your needs and contribute to your project's success.

Remember that the best manufacturer for your project may not necessarily be the largest or the cheapest. Instead, focus on finding a partner that offers the right combination of expertise, quality, service, and value for your specific requirements.

As you embark on your search for the ideal aluminum extrusion profile manufacturer, keep these key points in mind:

- Prioritize experience and industry-specific expertise

- Evaluate manufacturing capabilities and quality control measures

- Consider value-added services that can benefit your project

- Look for manufacturers committed to innovation and sustainability

- Don't underestimate the importance of good customer service and support

By following the guidelines outlined in this article and conducting thorough research, you'll be well-equipped to choose an aluminum extrusion profile manufacturer that can help bring your project to successful fruition.

Frequently Asked Questions

1. What are the main advantages of using aluminum extrusion profiles?

Aluminum extrusion profiles offer several advantages, including:

- Lightweight yet strong construction

- Corrosion resistance

- Versatility in design and application

- Cost-effectiveness for complex shapes

- Excellent thermal and electrical conductivity

- Recyclability and sustainability

2. How long does the aluminum extrusion process typically take?

The aluminum extrusion process itself is relatively quick, often taking only a few minutes for the actual extrusion. However, the total production time can vary depending on factors such as:

- Profile complexity

- Order volume

- Additional processing requirements (e.g., heat treatment, surface finishing)

- Die preparation (for custom profiles)

On average, lead times for standard profiles can range from a few days to a couple of weeks, while custom profiles may take several weeks to produce.

3. What are the most common aluminum alloys used in extrusion profiles?

The most commonly used aluminum alloys for extrusion profiles include:

- 6061: Known for its strength and corrosion resistance

- 6063: Offers good extrudability and surface finish

- 6005A: Provides excellent strength and weldability

- 7075: High-strength alloy often used in aerospace applications

- 5052: Known for its good formability and corrosion resistance

The choice of alloy depends on the specific requirements of your application, such as strength, weight, corrosion resistance, and formability.

4. How can I ensure the quality of aluminum extrusion profiles from a manufacturer?

To ensure the quality of aluminum extrusion profiles, consider the following steps:

- Request material certifications and test reports

- Ask about the manufacturer's quality control processes and certifications (e.g., ISO 9001)

- Inquire about in-process inspections and final quality checks

- Request samples for testing and evaluation

- Consider third-party inspections for large or critical orders

- Review the manufacturer's track record and customer references

5. What are the environmental considerations when choosing an aluminum extrusion profile manufacturer?

When considering the environmental impact of aluminum extrusion profile manufacturers, look for:

- Use of recycled aluminum in production

- Energy-efficient manufacturing processes

- Waste reduction and recycling programs

- Environmental certifications (e.g., ISO 14001)

- Sustainable packaging and shipping practices

- Commitment to reducing carbon footprint

Choosing a manufacturer with strong environmental practices can help reduce the overall environmental impact of your project and align with sustainability goals.

Citations:

[1] https://www.jh-aluminium.com/blog/Tips_on_Choosing_the_Right_Aluminum_Extrusion_Manufacturer_id09.html

[2] https://profileprecisionextrusions.com/choosing-an-aluminum-extrusion-manufacturer-partner/

[3] https://www.youtube.com/watch?v=Bc7o_sEdX8U

[4] https://www.freepik.com/free-photos-vectors/aluminum-extrusion

[5] https://dajcor.com/learning-centre/faq

[6] https://starext.com/news/aluminum-extrusion-finishing-fabrication-frequently-asked-questions-faq

[7] https://jmaluminium.com/choosing-an-aluminum-extrusion-manufacturer-what-to-consider-when-researching-a-partner/

[8] https://www.yjing-extrusion.com/how-to-choose-the-right-aluminum-extrusion-model-for-your-needs.html

[9] https://haluminium.com/hoonly-aluminium-extrusion-profile-faq/

[10] https://www.industrialprofile.com/aluminum-extrusion-profile-manufacturers-5-factors-to-consider/