Content Menu

● Understanding Aluminum Extrusions

>> Benefits of Aluminum Extrusions

● Key Considerations When Choosing Aluminum Extrusion Profiles

>> 1. Application Requirements

>> 2. Profile Shape and Design

>> 3. Material Specifications

>> 4. Finish Options

>> 5. Cost Considerations

>> 6. Supplier Capabilities

● Practical Tips for Selecting Aluminum Extrusion Profiles

● Conclusion

● Frequently Asked Questions

>> 1. What is the most common aluminum extrusion profile?

>> 2. Can aluminum extrusions be customized?

>> 3. What are the advantages of anodized aluminum?

>> 4. How do I determine the right alloy for my project?

>> 5. Are aluminum extrusions environmentally friendly?

Choosing the right aluminum extrusion profile is crucial for the success of your project, whether you are designing a new product, constructing a framework, or creating custom components. Aluminum extrusions are versatile, lightweight, and strong, making them an ideal choice for various applications. This article will guide you through the process of selecting the right aluminum extrusion profile for your needs, covering key considerations, types of profiles, and practical tips.

Understanding Aluminum Extrusions

Aluminum extrusion is a manufacturing process that involves shaping aluminum alloy by forcing it through a die. This process allows for the creation of complex shapes and profiles that can be used in a wide range of applications, from construction to automotive and aerospace industries. The resulting profiles can be customized in terms of size, shape, and finish, making them highly adaptable.

Benefits of Aluminum Extrusions

1. Lightweight: Aluminum is significantly lighter than steel, making it easier to handle and transport.

2. Corrosion Resistance: Aluminum naturally forms a protective oxide layer, which helps prevent corrosion.

3. Strength: Despite its lightweight nature, aluminum is strong and can withstand significant loads.

4. Versatility: Aluminum extrusions can be used in various applications, from structural components to decorative elements.

5. Recyclability: Aluminum is 100% recyclable, making it an environmentally friendly choice.

Key Considerations When Choosing Aluminum Extrusion Profiles

When selecting the right aluminum extrusion profile, consider the following factors:

1. Application Requirements

Identify the specific requirements of your project. Consider the following questions:

- What is the intended use of the extrusion?

- Will it be subjected to heavy loads or stress?

- Does it need to be lightweight or have a specific aesthetic?

Understanding the application will help you narrow down your options and select a profile that meets your needs.

2. Profile Shape and Design

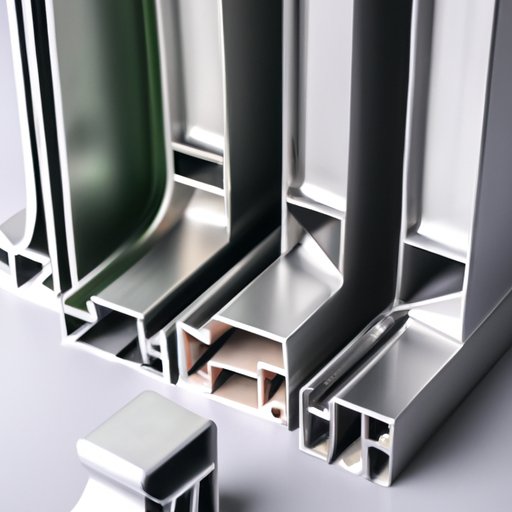

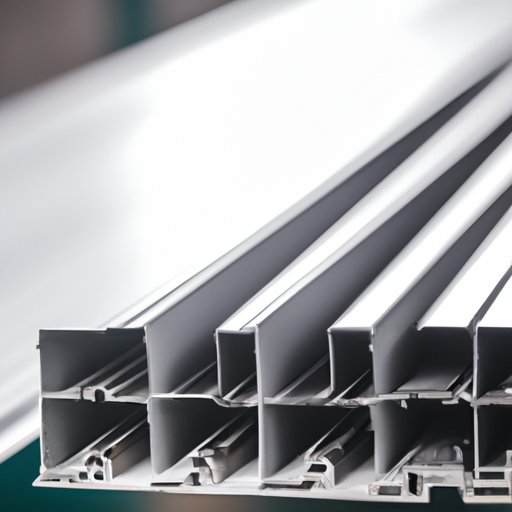

Aluminum extrusions come in various shapes, including:

- T-Slot Profiles: Ideal for modular construction and easy assembly.

- Hollow Tubes: Suitable for structural applications.

- Angles and Channels: Commonly used for framing and support.

Choose a profile shape that best fits your application needs. For instance, T-slot profiles are excellent for building frames and structures that require flexibility and reconfiguration, while hollow tubes provide strength and stability for load-bearing applications.

3. Material Specifications

Different aluminum alloys have varying properties. Common alloys used in extrusions include:

- 6061: Known for its good mechanical properties and weldability, making it suitable for structural applications.

- 6063: Often used for architectural applications due to its excellent finish and extrudability.

- 7075: A high-strength alloy suitable for aerospace applications, where weight and strength are critical.

Select an alloy that meets the strength, corrosion resistance, and weight requirements of your project. Understanding the properties of each alloy will help you make an informed decision.

4. Finish Options

Aluminum extrusions can be finished in several ways, including:

- Anodizing: Enhances corrosion resistance and allows for color options, making it ideal for architectural applications.

- Powder Coating: Provides a durable, colorful finish that can withstand harsh environments.

- Mill Finish: The natural finish of the extrusion, which can be polished or brushed for aesthetic purposes.

Consider the aesthetic and functional requirements of your project when choosing a finish. For example, if your project is exposed to the elements, a powder-coated finish may provide the durability you need.

5. Cost Considerations

Budget is always a factor in any project. While aluminum extrusions can be more expensive than other materials, their durability and low maintenance costs can make them a cost-effective choice in the long run. Get quotes from multiple suppliers to find the best price for your specific needs. Additionally, consider the total cost of ownership, which includes installation, maintenance, and potential replacement costs.

6. Supplier Capabilities

Choose a reputable supplier who can provide high-quality extrusions and has the capability to meet your specific requirements. Look for suppliers who offer customization options, quick turnaround times, and excellent customer service. A good supplier will also provide technical support and guidance throughout the selection process.

Practical Tips for Selecting Aluminum Extrusion Profiles

1. Prototype First: If possible, create a prototype of your design using the selected extrusion profile. This will help you identify any potential issues before full-scale production. Prototyping can save time and money by allowing you to test the design in real-world conditions.

2. Consult with Experts: Don't hesitate to reach out to engineers or designers who specialize in aluminum extrusions. Their expertise can provide valuable insights and help you make informed decisions. Collaborating with professionals can also lead to innovative solutions that you may not have considered.

3. Consider Assembly Methods: Think about how the extrusions will be assembled. Will you be using fasteners, welding, or other methods? Ensure that the profile you choose is compatible with your assembly method. For example, T-slot profiles are designed for easy assembly with standard fasteners, while some profiles may require specialized joining techniques.

4. Test for Strength: If your application requires high strength, consider conducting tests to ensure the selected profile can handle the expected loads. Load testing can help you verify that the extrusion will perform as needed in its intended application.

5. Stay Informed on Industry Trends: Keep up with the latest trends in aluminum extrusion technology and design. This knowledge can help you make better choices and stay competitive in your field. Attend industry conferences, read trade publications, and participate in online forums to stay updated.

Conclusion

Choosing the right aluminum extrusion profile for your needs involves careful consideration of various factors, including application requirements, profile shape, material specifications, finish options, cost, and supplier capabilities. By following the guidelines outlined in this article, you can make informed decisions that will lead to successful project outcomes.

Frequently Asked Questions

1. What is the most common aluminum extrusion profile?

The most common profiles are T-slot and rectangular tubes, as they offer versatility for various applications. T-slot profiles are particularly popular in modular construction and automation systems.

2. Can aluminum extrusions be customized?

Yes, aluminum extrusions can be customized in terms of shape, size, and finish to meet specific project requirements. Many suppliers offer custom extrusion services to create unique profiles tailored to your needs.

3. What are the advantages of anodized aluminum?

Anodized aluminum has enhanced corrosion resistance, improved surface hardness, and can be colored for aesthetic purposes. This makes it an excellent choice for outdoor applications and architectural elements.

4. How do I determine the right alloy for my project?

Consider the mechanical properties, corrosion resistance, and weight requirements of your application when selecting an alloy. Consulting with a materials engineer can also provide valuable insights into the best alloy for your specific needs.

5. Are aluminum extrusions environmentally friendly?

Yes, aluminum is 100% recyclable, making it an environmentally friendly choice for construction and manufacturing. Using recycled aluminum in extrusions also reduces energy consumption and greenhouse gas emissions compared to producing new aluminum.