Content Menu

● Understanding Aluminum Extrusion

● Key Considerations When Choosing an Aluminum Extrusion Manufacturer

>> 1. Experience and Expertise

>> 2. Manufacturing Capabilities

>> 3. Quality Control Measures

>> 4. Material Selection

>> 5. Customization and Design Support

>> 6. Cost Transparency

>> 7. Customer Service and Support

● How to Find Aluminum Extrusion Manufacturers Near You

● The Importance of Researching Potential Manufacturers

>> 1. Read Reviews and Testimonials

>> 2. Request Samples

>> 3. Visit Their Facility

● Visualizing the Aluminum Extrusion Process

● Additional Services Offered by Manufacturers

● Conclusion

● FAQ

>> 1. What should I look for in an aluminum extrusion manufacturer?

>> 2. How do I ensure quality in aluminum extrusions?

>> 3. Can I get custom shapes from an aluminum extrusion manufacturer?

>> 4. What are common applications for aluminum extrusions?

>> 5. How long does it take to receive my order after placing it?

● Citations:

When embarking on a project that requires aluminum extrusions, selecting the right manufacturer is crucial. The quality of the extrusions can significantly impact the success of your project, whether it's for construction, automotive, or any other industry. This guide will help you navigate the process of choosing the right aluminum extrusion manufacturer near you, ensuring that you find a partner who meets your specific needs.

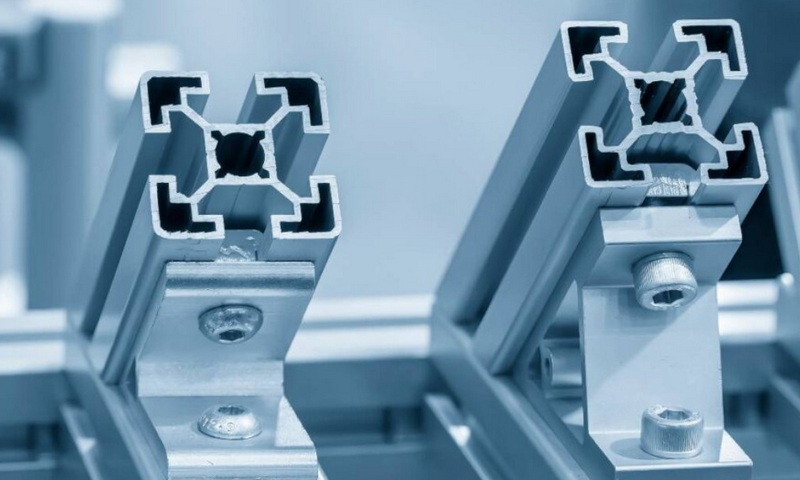

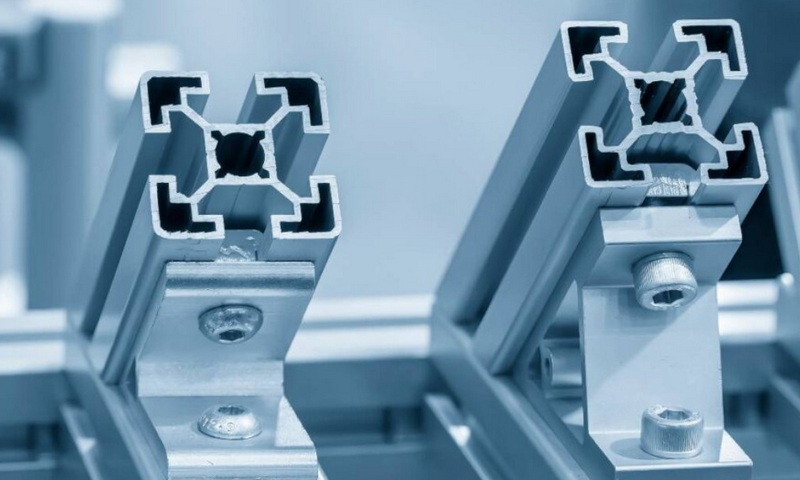

Understanding Aluminum Extrusion

Aluminum extrusion is a process where aluminum is forced through a die to create specific shapes and profiles. This method allows for the production of complex shapes that are lightweight yet strong. The versatility of aluminum makes it an ideal material for various applications, including:

- Construction: Windows, doors, and structural components.

- Automotive: Lightweight frames and components.

- Consumer Products: Electronics housing and furniture.

The benefits of aluminum extrusion include:

- High strength-to-weight ratio

- Corrosion resistance

- Design flexibility

- Cost-effectiveness in large-scale production

Key Considerations When Choosing an Aluminum Extrusion Manufacturer

To ensure you select the right aluminum extrusion manufacturer near you, consider the following factors:

1. Experience and Expertise

Look for manufacturers with a proven track record in aluminum extrusion. Companies that have been in the industry for several years will likely have refined their processes and can handle challenges effectively.

- Industry Experience: Check if they have experience in your specific industry or application. Specialized knowledge can lead to better product outcomes.

- Technical Knowledge: A knowledgeable team can provide valuable insights into design optimization and material selection.

2. Manufacturing Capabilities

Assess the manufacturer's production capabilities to ensure they can meet your project requirements.

- Equipment Quality: Modern machinery is essential for producing high-quality extrusions. Ensure they have state-of-the-art equipment capable of handling your specifications.

- Production Volume: Confirm that they can handle your required volume, whether it's a small batch or mass production. Some manufacturers may specialize in either small runs or large-scale production.

3. Quality Control Measures

Quality control is critical in aluminum extrusion manufacturing. Inquire about their quality assurance processes:

- Certifications: Look for ISO certifications or other relevant industry standards that demonstrate their commitment to quality.

- Inspection Procedures: Understand how they monitor quality throughout the production process. Regular inspections and testing can prevent defects.

4. Material Selection

The type of aluminum alloy used can affect the performance of your extrusions. Discuss with potential manufacturers about their material options:

- Alloy Variety: Ensure they offer a range of alloys suitable for your application (e.g., 6061, 6063). Different alloys have different properties that may be more suitable for specific applications.

- Sustainability Practices: Consider manufacturers who prioritize sustainable sourcing and recycling of materials. Environmentally-friendly practices are increasingly important in today's market.

5. Customization and Design Support

If your project requires custom designs, ensure the manufacturer can accommodate this need.

- Design Assistance: Some manufacturers offer engineering support to help refine your designs, which can save time and reduce costs.

- Prototyping Services: Check if they can produce prototypes before full-scale production. Prototyping allows you to test designs and make necessary adjustments without committing to large orders.

6. Cost Transparency

Understanding pricing structures is essential to avoid unexpected costs later on.

- Quotes and Estimates: Request detailed quotes that outline all costs involved, including tooling fees, material costs, and shipping charges.

- Minimum Order Quantities: Be aware of any minimum order requirements that could impact your budget. Some manufacturers may require larger orders to justify setup costs.

7. Customer Service and Support

A responsive customer service team can make a significant difference in your experience with a manufacturer.

- Communication: Ensure they are easy to contact and willing to answer questions promptly. Good communication is key during both the design phase and production.

- After-Sales Support: Consider what support they offer after delivery, such as handling defects or issues with orders. A manufacturer committed to customer satisfaction will be more likely to assist you after the sale.

How to Find Aluminum Extrusion Manufacturers Near You

Finding local manufacturers can simplify logistics and communication. Here are some strategies to locate aluminum extrusion manufacturers near you:

- Online Searches: Use search engines with keywords like "aluminum extrusion manufacturers near me" to find local options. This method often yields quick results.

- Industry Directories: Explore directories that list manufacturers by region or specialty. Websites like ThomasNet or industry-specific directories can be very helpful.

- Trade Shows and Expos: Attend industry events to meet potential suppliers face-to-face and see their products firsthand. Networking at these events can lead to valuable connections.

The Importance of Researching Potential Manufacturers

Before making a final decision, conducting thorough research on potential manufacturers is essential. Here are some steps you should take:

1. Read Reviews and Testimonials

Look for reviews from previous customers about their experiences with the manufacturer. Websites like Google Reviews, Yelp, or industry-specific forums can provide insights into customer satisfaction levels.

2. Request Samples

If possible, request samples of their previous work or prototypes relevant to your project needs. This will allow you to assess their quality firsthand before committing.

3. Visit Their Facility

If feasible, visiting the manufacturer's facility can provide valuable insight into their operations, equipment, and overall professionalism.

Visualizing the Aluminum Extrusion Process

Understanding the extrusion process can help you appreciate what goes into producing high-quality products. Below is a simplified overview of the aluminum extrusion process:

1. Billet Heating: The aluminum billet is heated to around 900°F (482°C) to make it malleable.

2. Extrusion Pressing: The heated billet is placed in an extrusion press where it is forced through a die.

3. Cooling: The extruded profile is cooled using air or water sprays.

4. Cutting and Finishing: Once cooled, it is cut to length and may undergo additional finishing processes like anodizing or painting.

For more detailed visuals, consider watching videos on platforms like YouTube that illustrate the aluminum extrusion process in action.

Additional Services Offered by Manufacturers

Many aluminum extrusion manufacturers offer additional services that could benefit your project:

- Secondary Operations: These may include machining, drilling, punching holes, or adding features post-extrusion.

- Finishing Options: Anodizing, powder coating, or painting can enhance aesthetics and corrosion resistance.

- Logistics Support: Some manufacturers provide shipping services or inventory management solutions which can streamline your supply chain.

Conclusion

Choosing the right aluminum extrusion manufacturer near you involves careful consideration of various factors including experience, capabilities, quality control measures, material selection, customization options, cost transparency, and customer support. By following this guide and asking the right questions, you can find a reliable partner who will contribute positively to your project's success.

FAQ

1. What should I look for in an aluminum extrusion manufacturer?

Look for experience in your industry, modern manufacturing capabilities, strict quality control measures, and good customer support.

2. How do I ensure quality in aluminum extrusions?

Inquire about certifications (like ISO), ask about their quality control processes, and request samples if possible.

3. Can I get custom shapes from an aluminum extrusion manufacturer?

Yes, many manufacturers offer customization services; just ensure they have design support available.

4. What are common applications for aluminum extrusions?

Aluminum extrusions are commonly used in construction (windows/doors), automotive parts, consumer electronics housings, and furniture components.

5. How long does it take to receive my order after placing it?

Lead times vary by manufacturer but typically range from a few weeks to several months depending on complexity and volume.

Citations:

[1] https://jmaluminium.com/choosing-an-aluminum-extrusion-manufacturer-what-to-consider-when-researching-a-partner/

[2] https://profileprecisionextrusions.com/choosing-an-aluminum-extrusion-manufacturer-partner/

[3] https://www.dreamstime.com/photos-images/aluminum-extrusion.html

[4] https://www.youtube.com/watch?v=iiGlq7408ME

[5] https://starext.com/news/aluminum-extrusion-finishing-fabrication-frequently-asked-questions-faq

[6] https://starext.com/frequently-asked-questions-about-aluminum-extrusions

[7] https://rpmindinc.com/follow-the-checklist-before-choosing-aluminum-extrusion-suppliers/

[8] https://www.alcirclebiz.com/blogs/finding-the-best-aluminium-extrusion-supplier-7-key-factors

[9] https://www.youtube.com/watch?v=vHkwq_2yY9E

[10] https://dajcor.com/learning-centre/faq

[11] https://americandouglasmetals.com/2023/10/03/key-considerations-in-selecting-an-aluminum-extrusions-profiles-provider/