Content Menu

● Understanding Aluminum Extrusion

● Key Factors to Consider When Choosing an Aluminum Extrusion Company

>> Experience and Expertise

>> Customization Capabilities

>> Material Selection

>> Manufacturing Facilities

>> Quality Assurance Standards

>> Customer Support and Communication

● Steps to Evaluate Potential Suppliers

● Industry Trends Affecting Aluminum Extrusion

● Conclusion

● FAQ

>> 1. What should I look for in an aluminum extrusion company?

>> 2. How important is experience in selecting an aluminum extruder?

>> 3. Can I get custom designs from any aluminum extrusion company?

>> 4. What types of industries do aluminum extrusion companies serve?

>> 5. How do I ensure quality in my aluminum extrusions?

Selecting the right aluminum extrusion company in California is crucial for ensuring the success of your project. With a plethora of options available, understanding the key factors that influence your decision can help you make an informed choice. This guide will cover essential considerations, tips for evaluating potential suppliers, and frequently asked questions to assist you in your selection process.

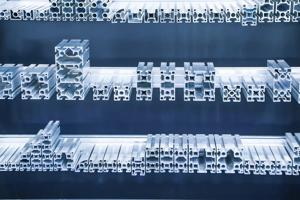

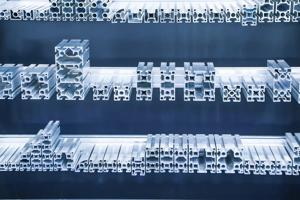

Understanding Aluminum Extrusion

Aluminum extrusion is a manufacturing process that involves shaping aluminum alloy into desired profiles by forcing it through a die. This versatile process allows for the creation of complex shapes with excellent strength-to-weight ratios, making it ideal for various applications across industries such as automotive, aerospace, construction, and consumer products.

The aluminum extrusion process begins with heating aluminum billets until they reach a malleable state. The heated aluminum is then pushed through a die using a hydraulic press. As the aluminum emerges from the die, it takes on the shape of the opening, allowing for various profiles to be created. After extrusion, the profiles can undergo additional processes such as cutting, machining, and finishing to meet specific customer requirements.

Key Factors to Consider When Choosing an Aluminum Extrusion Company

Experience and Expertise

One of the most critical factors to consider is the experience and expertise of the aluminum extrusion company. A provider with a solid track record and industry knowledge will likely deliver higher quality products. Look for companies that have been in business for several years and have successfully completed projects similar to yours.

Experienced companies often have established relationships with suppliers and can source high-quality materials at competitive prices. They are also more likely to have encountered and solved various challenges during the extrusion process, which can be invaluable when navigating complex projects.

Customization Capabilities

Every project has unique requirements, so it's essential to choose a company that offers customization options. A reliable aluminum extrusion provider should be able to accommodate complex designs, tight tolerances, and various finishing options. This flexibility can significantly impact the quality and functionality of your final product.

Customization may include:

- Profile Design: Tailoring the shape and dimensions of extrusions to fit specific applications.

- Surface Finishing: Options such as anodizing, painting, or powder coating to enhance appearance and corrosion resistance.

- Machining Services: Additional processes like drilling or milling to prepare extrusions for assembly.

Material Selection

Different aluminum alloys possess distinct properties that can affect the performance of your extruded products. Ensure that the company you choose has access to a wide range of aluminum alloys and understands their specific characteristics. This knowledge will help you select the best material for your project needs.

Common aluminum alloys used in extrusion include:

- 6061: Known for its good mechanical properties and weldability; suitable for structural applications.

- 6063: Often used for architectural applications due to its excellent finish and corrosion resistance.

- 7075: A high-strength alloy typically used in aerospace applications.

Manufacturing Facilities

Evaluate the manufacturing capabilities and facilities of potential suppliers. The company should have modern equipment and technology to handle your project's size and complexity. Adequate resources are crucial for meeting production timelines and maintaining consistent quality.

Advanced manufacturing technologies such as CNC machining centers, automated cutting machines, and robotic handling systems can enhance efficiency and precision in production. Companies that invest in state-of-the-art facilities are more likely to deliver high-quality products on time.

Quality Assurance Standards

The quality of the products should be paramount when selecting an aluminum extrusion company. Look for providers that adhere to strict quality control standards and hold relevant certifications (e.g., ISO 9001). This ensures that the extrusions you receive are of high quality and have passed rigorous testing procedures.

Quality assurance processes may include:

- Incoming Material Inspection: Ensuring raw materials meet specified standards before production begins.

- In-Process Quality Checks: Monitoring production processes to identify issues early on.

- Final Product Testing: Conducting tests on finished products to verify compliance with specifications.

Customer Support and Communication

Effective communication is vital for a successful partnership. Assess the company's customer support by evaluating their responsiveness, willingness to address concerns, and ability to provide timely updates on project progress. A dedicated point of contact can facilitate smoother collaboration.

A strong customer support team should be able to assist you throughout every stage of your project—from initial design discussions through production and delivery—ensuring all your needs are met promptly.

Steps to Evaluate Potential Suppliers

1. Research Companies: Start by researching aluminum extrusion companies in California. Look for those with positive reviews, testimonials, and case studies showcasing their work.

2. Request Quotes: Contact multiple suppliers to request quotes based on your project specifications. This will help you compare pricing structures and services offered.

3. Ask Questions: Prepare a list of questions to ask potential suppliers about their experience, capabilities, lead times, and post-extrusion services. This will give you insight into their operations and how well they align with your needs.

4. Visit Facilities: If possible, visit the manufacturing facilities of shortlisted companies. This allows you to assess their equipment, processes, and overall working environment firsthand.

5. Review Samples: Request samples of previous work or prototypes to evaluate the quality of their extrusions. This step can provide valuable insight into their craftsmanship.

6. Check References: Ask potential suppliers for references from previous clients who had similar projects completed. Speaking directly with past customers can provide insight into their experiences regarding product quality, delivery times, and customer service.

7. Evaluate Lead Times: Consider how quickly each supplier can deliver your products without compromising quality. Timely delivery is crucial in maintaining project schedules.

8. Assess Post-Extrusion Services: Determine if the company offers additional services such as assembly or logistics support after production is complete.

Industry Trends Affecting Aluminum Extrusion

Understanding current trends in the aluminum extrusion industry can also inform your decision-making process when selecting a supplier:

- Sustainability Practices: Many companies are adopting eco-friendly practices by utilizing recycled aluminum materials or implementing energy-efficient manufacturing processes.

- Technological Advancements: Innovations such as 3D printing are beginning to influence traditional extrusion methods by allowing for more complex designs at reduced costs.

- Market Demand Fluctuations: Staying informed about market demands can help you choose a supplier who is adaptable to changing conditions while still meeting your needs effectively.

Conclusion

Choosing the right aluminum extrusion company in California is vital for ensuring high-quality products that meet your project requirements. By considering factors such as experience, customization capabilities, material selection, manufacturing facilities, quality assurance standards, customer support, industry trends, and conducting thorough evaluations of potential suppliers, you can make an informed decision that sets your project up for success.

FAQ

1. What should I look for in an aluminum extrusion company?

When choosing an aluminum extrusion company, consider their experience, customization capabilities, material selection options, manufacturing facilities, quality assurance standards, and customer support.

2. How important is experience in selecting an aluminum extruder?

Experience is crucial as it often correlates with expertise in handling various projects effectively, understanding industry standards, and delivering high-quality products consistently.

3. Can I get custom designs from any aluminum extrusion company?

Not all companies offer custom designs; therefore, it's essential to verify that the provider has experience with complex shapes and can accommodate your specific requirements.

4. What types of industries do aluminum extrusion companies serve?

Aluminum extrusion companies serve various industries including automotive, aerospace, construction, electronics, consumer goods, military applications, and more.

5. How do I ensure quality in my aluminum extrusions?

To ensure quality in your aluminum extrusions, choose a supplier with strict quality control measures in place and relevant certifications such as ISO 9001.