Content Menu

● Introduction

● Understanding Aluminum Channels

>> Characteristics of Aluminum Channels

● Benefits of Using Aluminum U Channels

>> Lightweight and Durable

>> Corrosion Resistance

>> Versatility in Applications

● Choosing the Right Aluminum Channel

>> Size and Dimensions

>> Alloy Type

>> Finish

>> Consulting with Suppliers

● Common Applications of Aluminum U Channels

>> Structural Support in Buildings

>> Frameworks for Windows and Doors

>> Applications in Signage and Display Systems

● Conclusion

● Frequently Asked Questions

>> 1. What are the main advantages of using aluminum channels over other materials?

>> 2. How do I determine the right size of aluminum channel for my project?

>> 3. Can aluminum channels be customized for specific projects?

>> 4. What is the difference between 6061 and 6063 aluminum alloys?

>> 5. How can I ensure the longevity of aluminum channels in outdoor applications?

Introduction

When embarking on a construction or manufacturing project, selecting the right materials is crucial for ensuring structural integrity and functionality. Among the various materials available, aluminum has gained popularity due to its lightweight, durability, and versatility. One of the most commonly used forms of aluminum in construction is the aluminum channel, particularly the channel aluminum extrusion. This article will guide you through the process of choosing the right aluminum channel for your project, exploring the benefits, applications, and key considerations to keep in mind.

Understanding Aluminum Channels

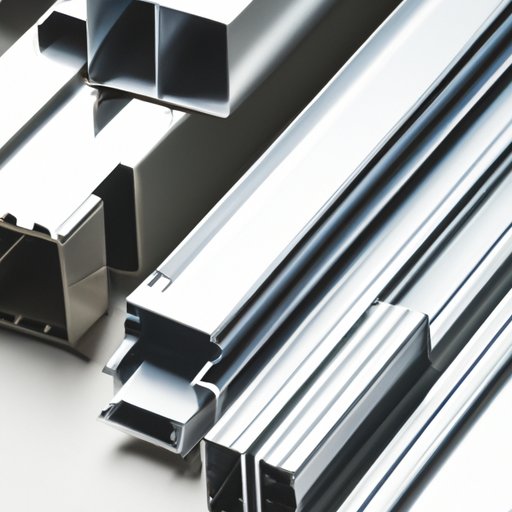

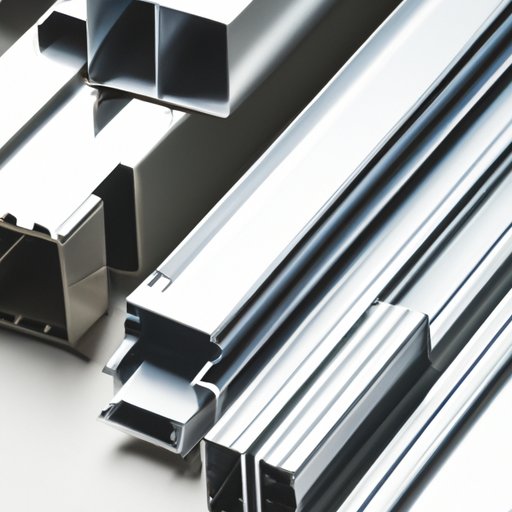

Aluminum channels are extruded profiles that come in various shapes, including U, C, and J channels. The most common type is the U channel, which features a "U" shape that provides excellent structural support. These channels are manufactured through a process called extrusion, where aluminum is forced through a die to create the desired shape. This method allows for precise dimensions and a smooth finish, making aluminum channels ideal for a wide range of applications.

Characteristics of Aluminum Channels

Aluminum channels possess several key characteristics that make them suitable for various projects:

- Lightweight: Aluminum is significantly lighter than steel, making it easier to handle and install.

- Corrosion Resistance: Aluminum naturally forms a protective oxide layer, preventing rust and degradation, which is particularly beneficial in outdoor or humid environments.

- Versatility: Aluminum channels can be used in numerous applications, from structural support to decorative elements.

Benefits of Using Aluminum U Channels

Lightweight and Durable

One of the primary advantages of using aluminum U channels is their lightweight nature. This characteristic not only simplifies transportation and installation but also reduces the overall weight of the structure, which can be crucial in projects where weight is a concern. Despite their lightness, aluminum channels are incredibly strong and can support significant loads, making them an excellent choice for structural applications.

Corrosion Resistance

Aluminum's inherent corrosion resistance is another significant benefit. Unlike steel, which can rust when exposed to moisture, aluminum channels maintain their integrity over time. This property is particularly important for projects that will be exposed to the elements, such as outdoor structures, marine applications, or environments with high humidity. By choosing aluminum channels, you can ensure that your project will withstand the test of time without the need for frequent maintenance or replacement.

Versatility in Applications

Aluminum U channels are incredibly versatile and can be used in a wide range of applications. Some common uses include:

- Structural Support: Aluminum channels are often used as beams or supports in construction projects, providing stability and strength to structures.

- Frameworks for Windows and Doors: The lightweight nature of aluminum makes it an ideal choice for window and door frames, allowing for easy installation and a sleek appearance.

- Signage and Display Systems: Aluminum channels can be used to create attractive and durable signage, as well as display systems for retail environments.

Choosing the Right Aluminum Channel

When selecting the right aluminum channel for your project, several factors should be considered to ensure you make the best choice.

Size and Dimensions

The first step in choosing an aluminum channel is determining the appropriate size and dimensions for your project. Consider the following:

- Width and Height: The width and height of the channel will affect its load-bearing capacity. Larger channels can support more weight, but they may also be heavier and more challenging to install.

- Thickness: The thickness of the channel walls will also impact its strength. Thicker walls provide greater durability but may add weight.

Alloy Type

Aluminum channels are available in various alloy types, each with its unique properties. Common alloys include:

- 6061: Known for its excellent mechanical properties and corrosion resistance, making it suitable for structural applications.

- 6063: Often used for architectural applications due to its smooth finish and ease of fabrication.

Choosing the right alloy will depend on the specific requirements of your project, including strength, corrosion resistance, and aesthetic considerations.

Finish

The finish of the aluminum channel can also play a significant role in its performance and appearance. Common finishes include:

- Mill Finish: The natural finish of aluminum after extrusion, which provides a raw, industrial look.

- Anodized Finish: A protective coating that enhances corrosion resistance and can be dyed for aesthetic purposes.

- Powder Coated Finish: A durable, colored finish that provides additional protection against the elements.

Consulting with Suppliers

When in doubt, consulting with aluminum channel suppliers can provide valuable insights. They can help you determine the best channel for your specific needs, taking into account factors such as load requirements, environmental conditions, and design preferences.

Common Applications of Aluminum U Channels

Aluminum U channels are used in a variety of applications across different industries. Here are some common uses:

Structural Support in Buildings

Aluminum channels are often used as structural supports in buildings, providing stability and strength to frameworks. Their lightweight nature allows for easier handling and installation, making them a popular choice among contractors.

Frameworks for Windows and Doors

In the construction of windows and doors, aluminum channels are frequently used to create frameworks. Their corrosion resistance ensures that these structures remain durable and functional over time, even in harsh weather conditions.

Applications in Signage and Display Systems

Aluminum channels are also widely used in signage and display systems. Their sleek appearance and ability to be easily customized make them ideal for creating attractive and functional displays in retail environments.

Conclusion

Choosing the right aluminum channel for your project is essential for ensuring structural integrity and functionality. By understanding the characteristics of aluminum channels, the benefits of using aluminum U channels, and the key factors to consider when selecting a channel, you can make an informed decision that meets your project's needs. Whether you are working on a construction project, creating a display system, or designing a framework for windows and doors, aluminum channels offer a versatile and durable solution.

Frequently Asked Questions

1. What are the main advantages of using aluminum channels over other materials?

Aluminum channels are lightweight, corrosion-resistant, and versatile, making them an excellent choice for various applications compared to heavier materials like steel.

2. How do I determine the right size of aluminum channel for my project?

Consider the load requirements, the dimensions of the structure, and the specific application to determine the appropriate size and thickness of the aluminum channel.

3. Can aluminum channels be customized for specific projects?

Yes, aluminum channels can be customized in terms of size, shape, and finish to meet the specific needs of your project.

4. What is the difference between 6061 and 6063 aluminum alloys?

6061 is known for its strength and versatility, making it suitable for structural applications, while 6063 is often used for architectural applications due to its smooth finish and ease of fabrication.

5. How can I ensure the longevity of aluminum channels in outdoor applications?

Choosing aluminum channels with a protective finish, such as anodized or powder-coated, can enhance their durability and resistance to the elements, ensuring they last longer in outdoor environments.