Content Menu

● Understanding 4080 Aluminum Extrusion

>> Key Features of 4080 Aluminum Extrusion

● Applications of 4080 Aluminum Extrusion

● Factors to Consider When Choosing 4080 Aluminum Extrusion

>> 1. Load Requirements

>> 2. Length and Size

>> 3. Finish Options

>> 4. Compatibility with Accessories

>> 5. Budget Constraints

● Tips for Using 4080 Aluminum Extrusion

>> 1. Plan Your Design

>> 2. Use the Right Tools

>> 3. Consider Joining Methods

>> 4. Test Stability

>> 5. Maintain Your Structure

● Additional Considerations for 4080 Aluminum Extrusion

>> Environmental Impact

>> Customization Options

>> Learning Resources

● Conclusion

● Frequently Asked Questions

>> 1. What is the weight capacity of 4080 aluminum extrusion?

>> 2. Can I cut 4080 aluminum extrusion at home?

>> 3. Is anodized aluminum extrusion better than raw aluminum?

>> 4. What tools do I need to assemble 4080 aluminum extrusion?

>> 5. Can I use 4080 aluminum extrusion for outdoor projects?

Choosing the right aluminum extrusion can significantly impact the success of your project, whether you're building a custom frame, a machine, or a prototype. Among the various profiles available, the 4080 aluminum extrusion stands out due to its versatility and strength. In this article, we will explore the key factors to consider when selecting the right 4080 aluminum extrusion for your needs, including its specifications, applications, and tips for effective use.

Understanding 4080 Aluminum Extrusion

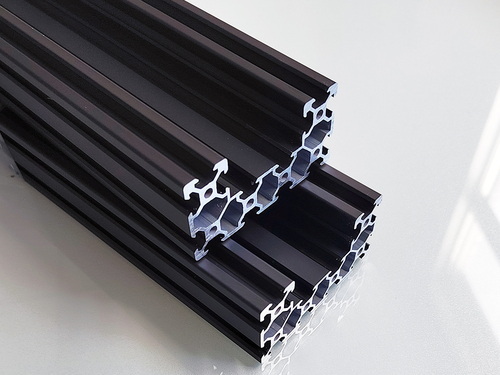

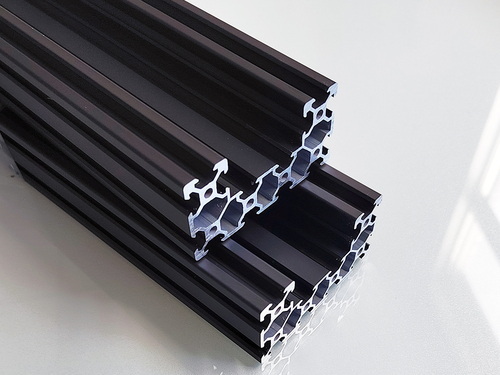

The term "4080" refers to the dimensions of the aluminum extrusion profile, specifically 40mm x 80mm. This T-slot profile is commonly used in various applications due to its robust design and ease of assembly. The T-slot design allows for the easy attachment of components, making it ideal for building frames, enclosures, and other structures.

Key Features of 4080 Aluminum Extrusion

1. Material Composition: Typically made from 6063 aluminum alloy, the 4080 extrusion offers excellent corrosion resistance and good mechanical properties. This makes it suitable for both indoor and outdoor applications.

2. Anodized Finish: Many 4080 extrusions come with an anodized finish, which enhances their durability and aesthetic appeal. Anodizing also provides additional protection against wear and tear.

3. Versatility: The 4080 profile can be used in a wide range of applications, from industrial machinery to DIY projects. Its compatibility with various accessories and connectors makes it a popular choice among engineers and hobbyists alike.

4. Ease of Assembly: The T-slot design allows for quick and easy assembly without the need for specialized tools. This feature is particularly beneficial for those who may not have extensive experience with construction or engineering.

Applications of 4080 Aluminum Extrusion

The 4080 aluminum extrusion is used in a variety of applications, including:

- Machine Frames: Its strength and rigidity make it an excellent choice for building machine frames that require stability and support.

- Workstations: Many manufacturers use 4080 extrusions to create ergonomic workstations that can be easily customized to fit specific needs.

- Enclosures: The profile is often used to build protective enclosures for sensitive equipment, providing both structural integrity and aesthetic appeal.

- Robotics: In the robotics field, 4080 aluminum extrusions are commonly used to construct robot frames and supports due to their lightweight yet sturdy nature.

- DIY Projects: Hobbyists and makers frequently use 4080 extrusions in various DIY projects, from furniture to custom tools.

Factors to Consider When Choosing 4080 Aluminum Extrusion

When selecting the right 4080 aluminum extrusion for your project, consider the following factors:

1. Load Requirements

Determine the load that the extrusion will need to support. The 4080 profile is strong, but understanding the weight and stress it will endure is crucial for ensuring safety and functionality. For instance, if you are building a frame for a heavy machine, you may need to reinforce the structure with additional supports or choose a thicker profile.

2. Length and Size

4080 extrusions come in various lengths. Choose a length that fits your project requirements while minimizing waste. If you need a specific size, many suppliers offer custom cutting services. It's also important to consider how the length will affect the overall stability of your structure.

3. Finish Options

Consider whether you need a specific finish for aesthetic or functional reasons. Anodized finishes provide additional protection and can enhance the appearance of your project. If your project will be exposed to harsh environments, a more robust finish may be necessary to prevent corrosion.

4. Compatibility with Accessories

Ensure that the 4080 extrusion is compatible with the accessories you plan to use, such as brackets, connectors, and fasteners. This compatibility will simplify the assembly process. Many manufacturers provide a range of compatible accessories designed specifically for their extrusions, which can save time and effort during assembly.

5. Budget Constraints

Evaluate your budget when selecting aluminum extrusions. While 4080 profiles are generally affordable, prices can vary based on material quality, finish, and supplier. It's wise to compare prices from different suppliers and consider bulk purchasing if you have multiple projects in mind.

Tips for Using 4080 Aluminum Extrusion

1. Plan Your Design

Before purchasing, create a detailed design of your project. This plan should include dimensions, load requirements, and a list of necessary components. A well-thought-out design will help you avoid costly mistakes. Consider using CAD software to visualize your design and make adjustments as needed.

2. Use the Right Tools

While assembly is straightforward, using the right tools can make the process smoother. A miter saw, drill, and T-slot nuts are essential for cutting and connecting the extrusions effectively. Additionally, having a level and measuring tape on hand will ensure that your assembly is precise.

3. Consider Joining Methods

There are various methods for joining aluminum extrusions, including using T-slot nuts, brackets, and welding. Choose the method that best suits your project's needs and your skill level. For example, T-slot nuts are ideal for quick assembly, while welding may provide a more permanent solution for high-stress applications.

4. Test Stability

Once assembled, test the stability of your structure before putting it to use. This step is crucial for ensuring safety, especially in applications involving heavy loads. You can perform a simple shake test to check for any wobbling or instability.

5. Maintain Your Structure

Regular maintenance can prolong the life of your aluminum extrusion projects. Check for signs of wear, especially in high-stress areas, and address any issues promptly. Cleaning the extrusions periodically will also help maintain their appearance and functionality.

Additional Considerations for 4080 Aluminum Extrusion

Environmental Impact

When choosing materials for your project, consider the environmental impact of aluminum production. Aluminum is highly recyclable, which can reduce its overall environmental footprint. If sustainability is a priority for your project, look for suppliers that offer recycled aluminum extrusions.

Customization Options

Many manufacturers offer customization options for aluminum extrusions, including custom lengths, finishes, and even unique profiles. If your project requires specific dimensions or features, don't hesitate to reach out to suppliers to discuss your needs. Custom solutions can often be more cost-effective than trying to adapt standard profiles.

Learning Resources

If you are new to working with aluminum extrusions, consider seeking out additional resources to enhance your knowledge. Online forums, instructional videos, and workshops can provide valuable insights and tips from experienced users. Engaging with a community of makers can also inspire new project ideas and solutions.

Conclusion

Choosing the right 4080 aluminum extrusion involves understanding your project requirements, evaluating the available options, and planning your design carefully. With its versatility and strength, the 4080 profile can be an excellent choice for a wide range of applications. By considering factors such as load requirements, finish options, and compatibility with accessories, you can ensure that your project is both functional and aesthetically pleasing.

Frequently Asked Questions

1. What is the weight capacity of 4080 aluminum extrusion?

The weight capacity depends on the specific application and design, but 4080 extrusions are generally strong enough to support significant loads when properly assembled.

2. Can I cut 4080 aluminum extrusion at home?

Yes, you can cut 4080 aluminum extrusion at home using a miter saw or a band saw. Ensure you use the appropriate blade for aluminum to achieve a clean cut.

3. Is anodized aluminum extrusion better than raw aluminum?

Anodized aluminum offers better corrosion resistance and a more attractive finish compared to raw aluminum, making it a preferred choice for many applications.

4. What tools do I need to assemble 4080 aluminum extrusion?

Basic tools include a miter saw, drill, T-slot nuts, and a wrench. Depending on your design, you may also need additional fasteners and brackets.

5. Can I use 4080 aluminum extrusion for outdoor projects?

Yes, 4080 aluminum extrusion is suitable for outdoor projects, especially if it has an anodized finish that provides additional protection against the elements.