Content Menu

● Introduction

● Understanding 4020 Aluminum Extrusions

>> Key Features of 4020 Aluminum Extrusions

● Key Benefits of 4020 Aluminum Extrusions

>> Lightweight and Strong

>> Versatility in Applications

>> Ease of Fabrication

>> Cost-Effectiveness

● Common Applications of 4020 Aluminum Extrusions

>> Structural Frameworks

>> Machinery and Equipment

>> Custom Projects

● Customization Options for 4020 Aluminum Extrusions

>> Available Finishes and Treatments

>> Custom Lengths and Shapes

● Conclusion

● Frequently Asked Questions

>> 1. What are the main advantages of using 4020 aluminum extrusions?

>> 2. In what industries are 4020 aluminum extrusions commonly used?

>> 3. Can 4020 aluminum extrusions be customized?

>> 4. How do I determine the right length of 4020 aluminum extrusion for my project?

>> 5. Are there any maintenance requirements for structures made with 4020 aluminum extrusions?

Introduction

Aluminum extrusions have become a staple in various industries due to their lightweight, strength, and versatility. Among the many profiles available, the 4020 aluminum extrusion stands out for its unique dimensions and applications. This article will guide you through the process of selecting the right 4020 aluminum profile for your specific needs, exploring its features, benefits, and common applications.

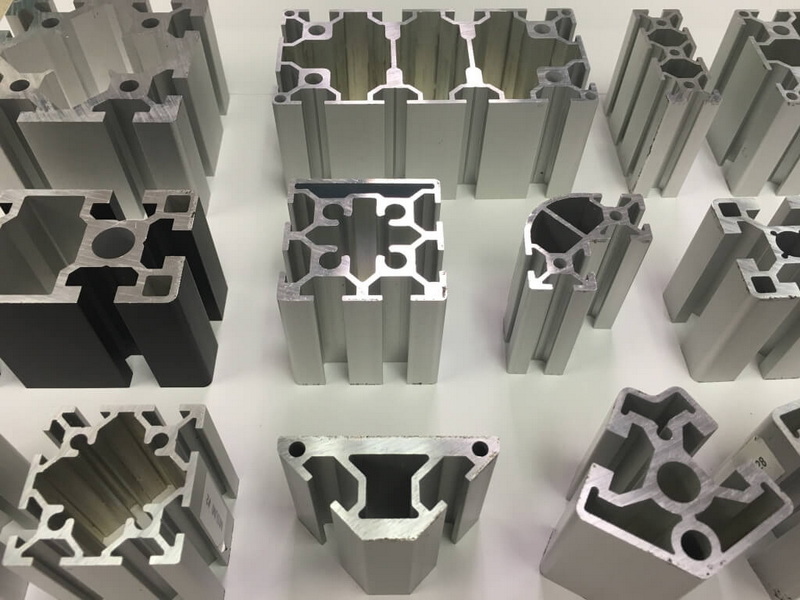

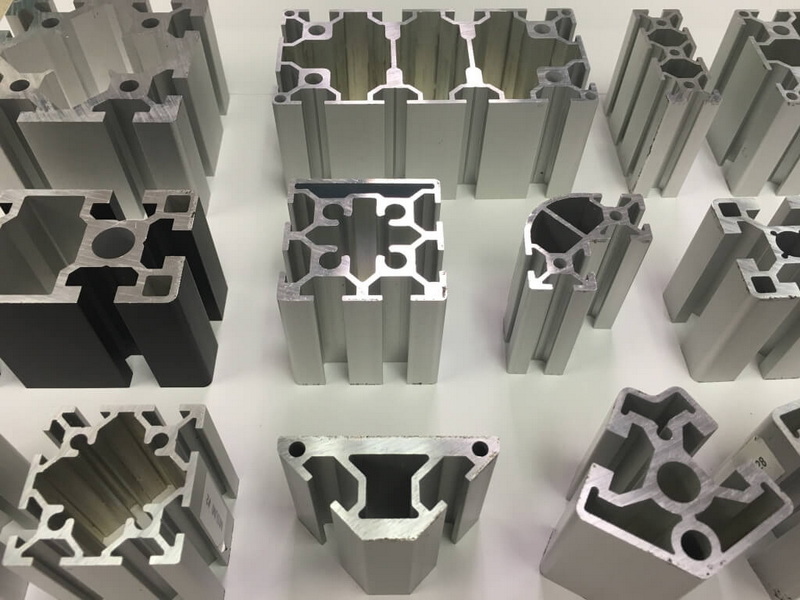

Understanding 4020 Aluminum Extrusions

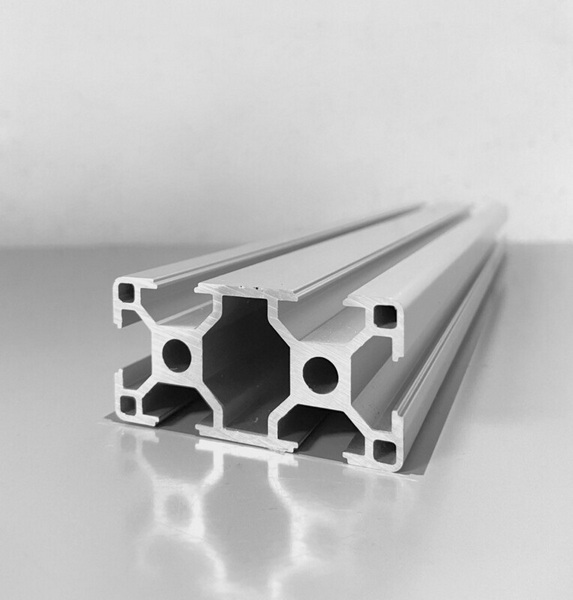

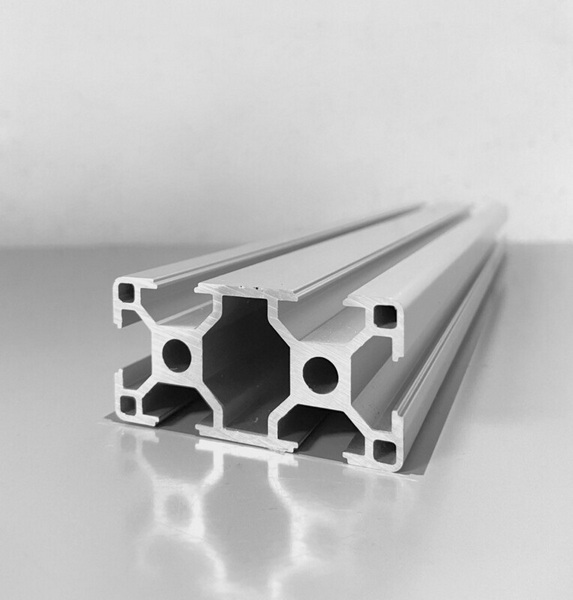

The 4020 aluminum extrusion is characterized by its dimensions, measuring 40mm by 20mm. This profile is part of the T-slot aluminum extrusion family, which features grooves along its length, allowing for easy assembly and integration with other components. The 4020 profile is often used in constructing frames, supports, and various structures due to its robust design and adaptability.

Key Features of 4020 Aluminum Extrusions

- Lightweight and Strong: Aluminum is known for its excellent strength-to-weight ratio, making the 4020 profile ideal for applications where weight savings are crucial without compromising structural integrity.

- Versatile Design: The T-slot design allows for easy customization and modification, enabling users to create complex structures with minimal effort.

- Corrosion Resistance: Aluminum naturally resists corrosion, making the 4020 profile suitable for both indoor and outdoor applications.

Key Benefits of 4020 Aluminum Extrusions

Lightweight and Strong

One of the most significant advantages of using 4020 aluminum extrusions is their lightweight nature. This characteristic is particularly beneficial in industries such as aerospace and automotive, where reducing weight can lead to improved fuel efficiency and performance. Despite being lightweight, the 4020 profile maintains a high level of strength, making it suitable for structural applications.

Versatility in Applications

The versatility of the 4020 aluminum extrusion allows it to be used in a wide range of applications. From industrial machinery to custom furniture, the possibilities are nearly endless. The profile can be easily cut, drilled, and assembled, making it a favorite among engineers and designers.

Ease of Fabrication

The fabrication process for 4020 aluminum extrusions is straightforward. The profile can be easily machined, allowing for precise cuts and modifications. This ease of fabrication means that projects can be completed more quickly, saving both time and money.

Cost-Effectiveness

When considering the overall cost of a project, the use of 4020 aluminum extrusions can lead to significant savings. The lightweight nature of aluminum reduces shipping costs, while the ease of assembly minimizes labor expenses. Additionally, the durability of aluminum means that structures built with 4020 profiles require less maintenance over time.

Common Applications of 4020 Aluminum Extrusions

Structural Frameworks

One of the most common uses for 4020 aluminum extrusions is in the construction of structural frameworks. These frameworks can be found in various settings, including manufacturing facilities, warehouses, and even residential buildings. The strength and stability of the 4020 profile make it an excellent choice for supporting heavy loads.

Machinery and Equipment

In industrial settings, 4020 aluminum extrusions are often used to create frames for machinery and equipment. The ability to customize the profile allows for the design of equipment that meets specific operational requirements. Additionally, the lightweight nature of aluminum makes it easier to move and install machinery.

Custom Projects

The flexibility of the 4020 aluminum extrusion makes it ideal for custom projects. Whether you are designing a unique display stand or a specialized workstation, the T-slot design allows for easy adjustments and modifications. This adaptability is a significant advantage for designers and engineers looking to create tailored solutions.

Customization Options for 4020 Aluminum Extrusions

Available Finishes and Treatments

The 4020 aluminum extrusion can be finished in various ways to enhance its appearance and performance. Common finishes include anodizing, powder coating, and painting. Anodizing provides a durable, corrosion-resistant surface, while powder coating offers a wide range of color options. These finishes not only improve aesthetics but also increase the longevity of the profile.

Custom Lengths and Shapes

One of the significant advantages of aluminum extrusions is the ability to order custom lengths and shapes. This customization ensures that the 4020 profile fits perfectly into your design, reducing waste and improving efficiency. Many suppliers offer cutting services, allowing you to receive the exact dimensions needed for your project.

Conclusion

Choosing the right 4020 aluminum profile for your application involves understanding its features, benefits, and potential uses. The lightweight, strong, and versatile nature of the 4020 aluminum extrusion makes it an excellent choice for a wide range of projects, from structural frameworks to custom machinery. By considering the customization options available, you can ensure that your design meets your specific needs while maximizing efficiency and cost-effectiveness.

Frequently Asked Questions

1. What are the main advantages of using 4020 aluminum extrusions?

The main advantages include their lightweight nature, high strength, versatility in applications, ease of fabrication, and cost-effectiveness.

2. In what industries are 4020 aluminum extrusions commonly used?

4020 aluminum extrusions are commonly used in industries such as aerospace, automotive, manufacturing, and construction.

3. Can 4020 aluminum extrusions be customized?

Yes, 4020 aluminum extrusions can be customized in terms of length, shape, and finish to meet specific project requirements.

4. How do I determine the right length of 4020 aluminum extrusion for my project?

To determine the right length, consider the dimensions of your design and any specific requirements for assembly. It's often beneficial to consult with a supplier for guidance.

5. Are there any maintenance requirements for structures made with 4020 aluminum extrusions?

Structures made with 4020 aluminum extrusions require minimal maintenance due to aluminum's corrosion resistance. Regular cleaning and inspection are recommended to ensure longevity.