Content Menu

● Understanding Aluminum Extrusions

● Benefits of Using 30x30 Aluminum Extrusions

● Key Considerations When Choosing 30x30 Aluminum Extrusions

>> Load Requirements

>> Environmental Conditions

>> Length and Size

>> Surface Finish

>> Assembly Method

● Practical Tips for Selecting 30x30 Aluminum Extrusions

>> Consult with Suppliers

>> Prototype Your Design

>> Consider Modular Designs

>> Utilize CAD Software

>> Evaluate Cost vs. Performance

● Applications of 30x30 Aluminum Extrusions

>> Industrial Automation

>> Furniture Design

>> Robotics

>> Display and Exhibition Stands

>> DIY Projects

● Conclusion

● Frequently Asked Questions

>> 1. What is the maximum load capacity of a 30x30 aluminum extrusion?

>> 2. Can I cut 30x30 aluminum extrusions to size?

>> 3. What is the difference between anodized and painted aluminum extrusions?

>> 4. Are 30x30 aluminum extrusions suitable for outdoor use?

>> 5. How do I assemble structures using 30x30 aluminum extrusions?

Choosing the right aluminum extrusion for your project can significantly impact the performance, durability, and aesthetics of your final product. Among the various sizes and profiles available, the 30x30 aluminum extrusion is a popular choice due to its versatility and strength. This article will guide you through the process of selecting the right 30x30 aluminum extrusion for your specific application, covering key considerations, benefits, and practical tips.

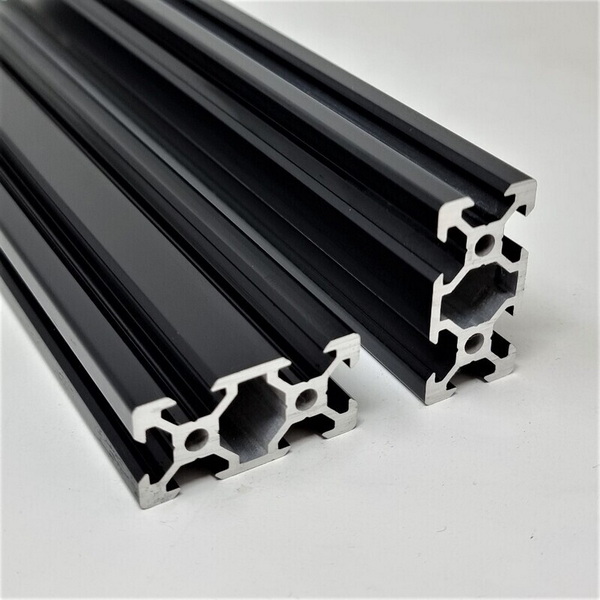

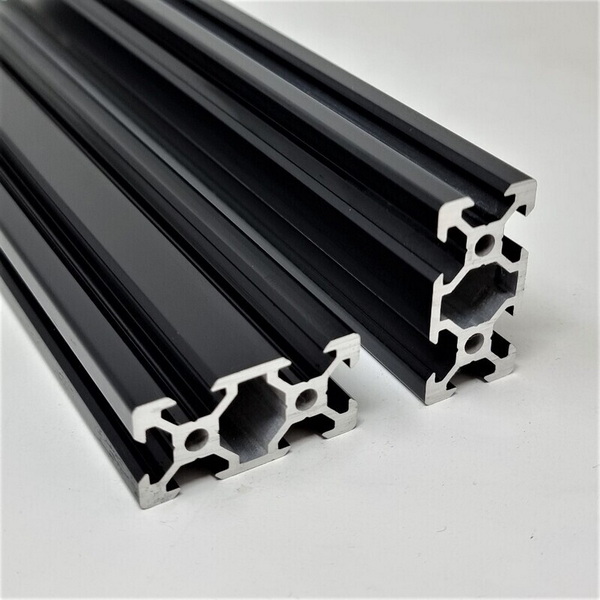

Understanding Aluminum Extrusions

Aluminum extrusions are created by forcing aluminum alloy through a die to create a specific cross-sectional shape. This process allows for the production of complex shapes that are lightweight yet strong, making aluminum extrusions ideal for a wide range of applications, from structural frameworks to decorative elements.

Benefits of Using 30x30 Aluminum Extrusions

1. Strength and Durability: The 30x30 profile provides excellent structural integrity, making it suitable for load-bearing applications. Aluminum is also resistant to corrosion, ensuring longevity in various environments.

2. Versatility: The 30x30 extrusion can be used in numerous applications, including machinery frames, workstations, and display stands. Its square shape allows for easy assembly and integration with other components.

3. Lightweight: Compared to steel and other materials, aluminum is significantly lighter, which can reduce shipping costs and make handling easier during assembly.

4. Aesthetic Appeal: Aluminum extrusions can be anodized or painted, allowing for customization in appearance. This is particularly beneficial for consumer-facing products where aesthetics matter.

5. Ease of Assembly: The T-slot design of many aluminum extrusions, including the 30x30 profile, allows for quick and easy assembly using standard fasteners. This can save time and labor costs during construction.

Key Considerations When Choosing 30x30 Aluminum Extrusions

When selecting the right 30x30 aluminum extrusion for your application, consider the following factors:

Load Requirements

Determine the load that the extrusion will need to support. This includes both static loads (weight of the structure itself) and dynamic loads (forces applied during operation). The 30x30 profile is robust, but understanding the specific load requirements will help you choose the right thickness and alloy.

Environmental Conditions

Consider the environment in which the extrusion will be used. Will it be exposed to moisture, chemicals, or extreme temperatures? Aluminum is generally resistant to corrosion, but certain alloys perform better in specific environments. For example, 6061 aluminum is often used for outdoor applications due to its excellent corrosion resistance.

Length and Size

While the 30x30 profile is standardized, you may need to cut the extrusions to specific lengths for your project. Ensure that you have the necessary tools for cutting and that you account for any waste material during the cutting process.

Surface Finish

The surface finish of the aluminum extrusion can affect both its appearance and performance. Anodizing provides a protective layer that enhances corrosion resistance and can be colored for aesthetic purposes. Consider whether a specific finish is required for your application.

Assembly Method

Think about how the extrusions will be assembled. Will you be using standard fasteners, or do you need specialized connectors? The T-slot design of the 30x30 aluminum extrusion allows for various assembly methods, making it adaptable to different construction techniques.

Practical Tips for Selecting 30x30 Aluminum Extrusions

Consult with Suppliers

Engage with suppliers who specialize in aluminum extrusions. They can provide valuable insights into the best alloys and profiles for your specific needs. Many suppliers also offer design assistance and can help you optimize your extrusion choices.

Prototype Your Design

Before committing to a large order, consider creating a prototype using the 30x30 aluminum extrusion. This allows you to test the design, assess load-bearing capabilities, and make any necessary adjustments before full-scale production.

Consider Modular Designs

If your application allows, consider using modular designs that can be easily reconfigured. The 30x30 aluminum extrusion is ideal for modular systems, enabling you to adapt your design as needs change.

Utilize CAD Software

Using computer-aided design (CAD) software can help you visualize your project and ensure that the dimensions and specifications of the 30x30 aluminum extrusion fit your design requirements. Many CAD programs have libraries of standard profiles, including aluminum extrusions.

Evaluate Cost vs. Performance

While it may be tempting to choose the least expensive option, consider the long-term performance and durability of the extrusion. Investing in high-quality aluminum extrusions can save you money in maintenance and replacement costs over time.

Applications of 30x30 Aluminum Extrusions

The 30x30 aluminum extrusion is used in a variety of applications across different industries. Here are some common uses:

Industrial Automation

In industrial settings, 30x30 aluminum extrusions are often used to create frames for machinery, conveyor systems, and workstations. Their strength and modularity make them ideal for building custom solutions that can be easily modified as production needs change.

Furniture Design

The aesthetic appeal of aluminum extrusions makes them a popular choice in furniture design. Designers use 30x30 profiles to create modern, sleek furniture pieces that are both functional and visually appealing. The ability to anodize or paint the extrusions allows for a wide range of design options.

Robotics

In robotics, 30x30 aluminum extrusions are frequently used to construct the frames and supports for robotic arms and other automated systems. Their lightweight nature helps improve the efficiency of robotic movements while maintaining structural integrity.

Display and Exhibition Stands

Exhibition stands and display units often utilize 30x30 aluminum extrusions due to their versatility and ease of assembly. These extrusions can be quickly assembled and disassembled, making them ideal for trade shows and exhibitions where portability is essential.

DIY Projects

For hobbyists and DIY enthusiasts, 30x30 aluminum extrusions provide a robust framework for various projects, from custom shelving units to home automation systems. The ease of assembly and availability of accessories make it a favorite among makers.

Conclusion

Choosing the right 30x30 aluminum extrusion for your application involves careful consideration of various factors, including load requirements, environmental conditions, and assembly methods. By understanding the benefits and practical applications of aluminum extrusions, you can make informed decisions that enhance the performance and aesthetics of your projects.

Frequently Asked Questions

1. What is the maximum load capacity of a 30x30 aluminum extrusion?

The load capacity depends on the specific alloy, wall thickness, and length of the extrusion. It is essential to consult load charts provided by manufacturers for accurate specifications.

2. Can I cut 30x30 aluminum extrusions to size?

Yes, 30x30 aluminum extrusions can be cut to the desired length using standard cutting tools. Ensure you have the right equipment and safety measures in place.

3. What is the difference between anodized and painted aluminum extrusions?

Anodizing creates a protective oxide layer that enhances corrosion resistance and can be colored, while painting applies a layer of paint that may not provide the same level of protection.

4. Are 30x30 aluminum extrusions suitable for outdoor use?

Yes, 30x30 aluminum extrusions are suitable for outdoor use, especially when made from corrosion-resistant alloys like 6061.

5. How do I assemble structures using 30x30 aluminum extrusions?

Structures can be assembled using T-slot fasteners, brackets, and connectors designed for aluminum extrusions. The T-slot design allows for flexible and easy assembly.