Content Menu

● Introduction

● Understanding 3060 Aluminum Extrusions

● Benefits of Using 3060 Aluminum Extrusions

>> Lightweight and Strong

>> Versatility in Applications

>> Ease of Assembly

>> Durability and Maintenance

>> Cost-Effectiveness

● How to Choose the Right 3060 Aluminum Profile for Your DIY CNC Applications

>> Determine Your Project Requirements

>> Consider the Type of CNC Machine

>> Evaluate Additional Features

>> Think About Future Modifications

● Conclusion

● Related Questions

>> 1. What are the advantages of using aluminum extrusions in CNC applications?

>> 2. How do I determine the load capacity of a 3060 aluminum profile?

>> 3. Can I use 3060 aluminum extrusions for outdoor applications?

>> 4. What tools do I need to assemble 3060 aluminum profiles?

>> 5. Are there any specific maintenance tips for aluminum extrusions?

Introduction

In the world of DIY projects, especially in the realm of CNC (Computer Numerical Control) machining, the choice of materials can significantly impact the quality and efficiency of your work. One of the most popular materials used in CNC applications is aluminum, particularly the 3060 aluminum extrusion. This article will explore the benefits of using 3060 aluminum profiles, how to select the right one for your projects, and the various applications where these profiles excel.

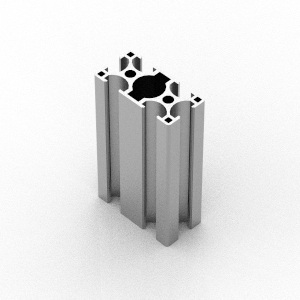

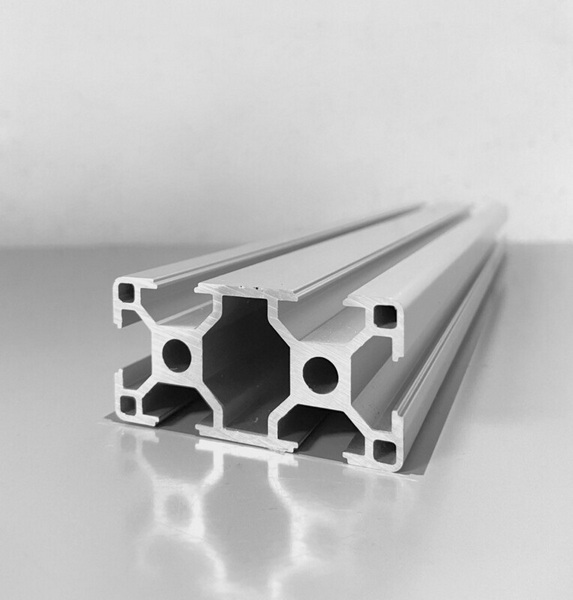

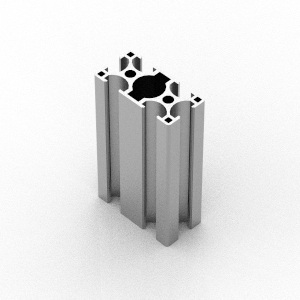

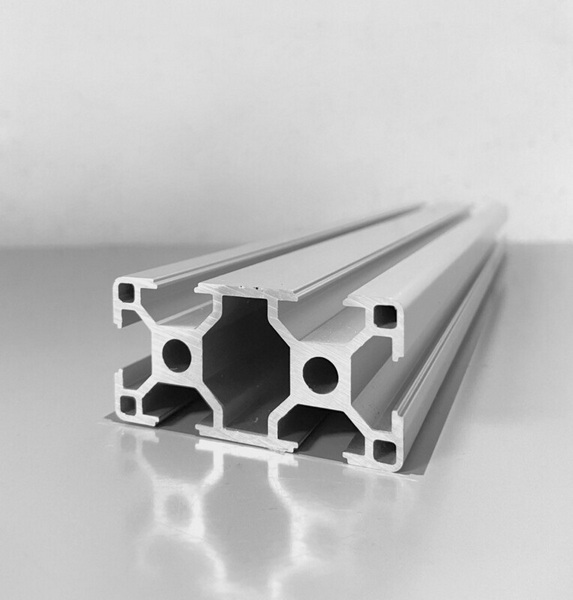

Understanding 3060 Aluminum Extrusions

3060 aluminum extrusions are characterized by their dimensions of 30mm by 60mm, making them a versatile choice for a wide range of applications. The T-slot design allows for easy assembly and customization, which is particularly beneficial for DIY enthusiasts and professionals alike. The aluminum used in these extrusions is lightweight yet strong, providing an excellent strength-to-weight ratio that is essential for CNC applications.

Benefits of Using 3060 Aluminum Extrusions

Lightweight and Strong

One of the primary advantages of 3060 aluminum extrusions is their lightweight nature. Aluminum is known for being significantly lighter than steel, which makes it easier to handle and transport. Despite its lightness, aluminum maintains a high level of strength, making it suitable for structural applications. This combination of lightweight and strength is particularly important in CNC applications, where precision and stability are crucial.

Versatility in Applications

The versatility of 3060 aluminum profiles is another reason they are favored in DIY CNC projects. These profiles can be used in various applications, including:

- CNC Machine Frames: The rigidity and strength of 3060 aluminum extrusions make them ideal for constructing the frames of CNC machines. A sturdy frame ensures that the machine operates smoothly and accurately.

- Workstations: Many DIY enthusiasts use 3060 aluminum profiles to build custom workstations. The modular nature of these extrusions allows for easy adjustments and expansions as your projects grow.

- Enclosures: If you need to create an enclosure for your CNC machine or other equipment, 3060 aluminum extrusions can provide a robust and aesthetically pleasing solution.

Ease of Assembly

The T-slot design of 3060 aluminum extrusions simplifies the assembly process. This feature allows users to connect multiple profiles without the need for complex tools or fasteners. You can easily slide in brackets, connectors, and other components, making it straightforward to create custom structures. This ease of assembly is particularly beneficial for those who may not have extensive experience in construction or machining.

Durability and Maintenance

Aluminum is naturally resistant to corrosion, but many 3060 aluminum extrusions come with an anodized finish that enhances this property. Anodizing not only protects the aluminum from environmental factors but also provides a sleek, professional appearance. Maintenance is minimal, as regular cleaning with mild soap and water is usually sufficient to keep the profiles looking new.

Cost-Effectiveness

When considering materials for your DIY CNC projects, cost is always a factor. 3060 aluminum extrusions offer a cost-effective solution due to their durability and low maintenance requirements. While the initial investment may be higher than some other materials, the long-term savings from reduced maintenance and replacement costs make aluminum a wise choice.

How to Choose the Right 3060 Aluminum Profile for Your DIY CNC Applications

Choosing the right 3060 aluminum profile for your CNC applications involves several considerations. Here are some key factors to keep in mind:

Determine Your Project Requirements

Before selecting a 3060 aluminum profile, it's essential to understand the specific requirements of your project. Consider the following:

- Load Capacity: Assess the weight and load that the profile will need to support. This will help you determine the thickness and type of aluminum extrusion required.

- Dimensions: Ensure that the dimensions of the 3060 profile fit your design specifications. The 30mm x 60mm size is versatile, but you may need to consider length and additional features based on your project.

Consider the Type of CNC Machine

Different CNC machines have varying requirements. For instance, a CNC router may require a different setup compared to a CNC mill. Understanding the specific needs of your machine will guide you in selecting the appropriate aluminum profile.

Evaluate Additional Features

Some 3060 aluminum extrusions come with additional features, such as pre-drilled holes or integrated mounting points. These features can save time during assembly and enhance the overall functionality of your project. Evaluate whether these features align with your project goals.

Think About Future Modifications

If you anticipate making modifications or expansions to your project in the future, consider choosing profiles that allow for easy adjustments. The modular nature of 3060 aluminum extrusions makes them ideal for projects that may evolve over time.

Conclusion

In conclusion, 3060 aluminum extrusions are an excellent choice for DIY CNC applications due to their lightweight, strength, versatility, and ease of assembly. By understanding the benefits and carefully considering your project requirements, you can select the right aluminum profile to enhance your CNC projects. Whether you are building a machine frame, workstation, or enclosure, 3060 aluminum profiles provide a reliable and cost-effective solution.

Related Questions

1. What are the advantages of using aluminum extrusions in CNC applications?

Aluminum extrusions offer a lightweight yet strong material, ease of assembly, and resistance to corrosion, making them ideal for CNC applications.

2. How do I determine the load capacity of a 3060 aluminum profile?

To determine the load capacity, consider the thickness of the profile, the type of aluminum used, and the specific design of your project.

3. Can I use 3060 aluminum extrusions for outdoor applications?

Yes, anodized aluminum extrusions are suitable for outdoor use due to their corrosion resistance, but ensure they are protected from extreme weather conditions.

4. What tools do I need to assemble 3060 aluminum profiles?

Typically, you will need basic hand tools such as an Allen wrench, a saw for cutting to length, and possibly a drill for additional mounting points.

5. Are there any specific maintenance tips for aluminum extrusions?

Regular cleaning with mild soap and water is usually sufficient. Avoid abrasive cleaners that could scratch the anodized surface.