Content Menu

● Introduction

● Understanding 2080 Aluminum Extrusion

>> Key Features of 2080 Aluminum Extrusion

● Key Benefits of 2080 Aluminum Extrusion

>> Lightweight and Strong

>> Versatility in Applications

>> Ease of Assembly

>> Cost-Effectiveness

● Common Applications of 2080 Aluminum Extrusion

● Best Practices for Working with 2080 Aluminum Extrusion

>> Measuring and Cutting

>> Assembly Techniques

>> Finishing Touches

>> Regular Maintenance

● Conclusion

● Related Questions

>> 1. What are the advantages of using 2080 aluminum extrusion over other materials?

>> 2. Can I use 2080 aluminum extrusion for outdoor applications?

>> 3. How do I cut 2080 aluminum extrusion accurately?

>> 4. What tools do I need to assemble structures with 2080 aluminum extrusion?

>> 5. Is it possible to customize the length of 2080 aluminum extrusion?

Introduction

In the world of manufacturing and engineering, the choice of materials can significantly impact the efficiency, durability, and overall success of a project. Among the various materials available, aluminum extrusion stands out due to its lightweight, strength, and versatility. Specifically, the 2080 aluminum extrusion profile has gained popularity in CNC applications for its unique properties and adaptability. This article will explore how to choose the right 2080 aluminum profile for your CNC applications, highlighting its benefits, applications, and best practices for use.

Understanding 2080 Aluminum Extrusion

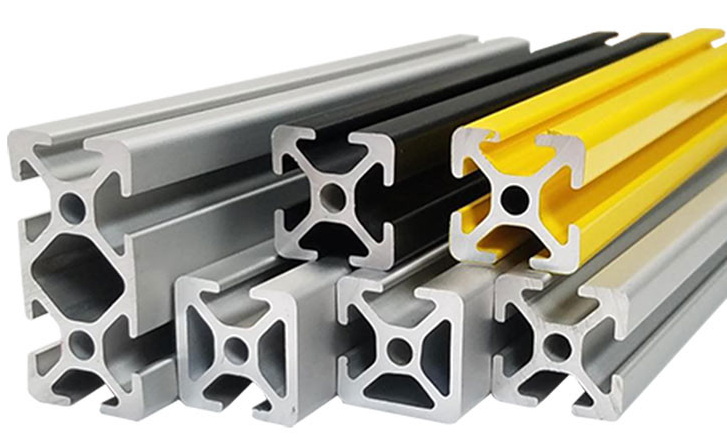

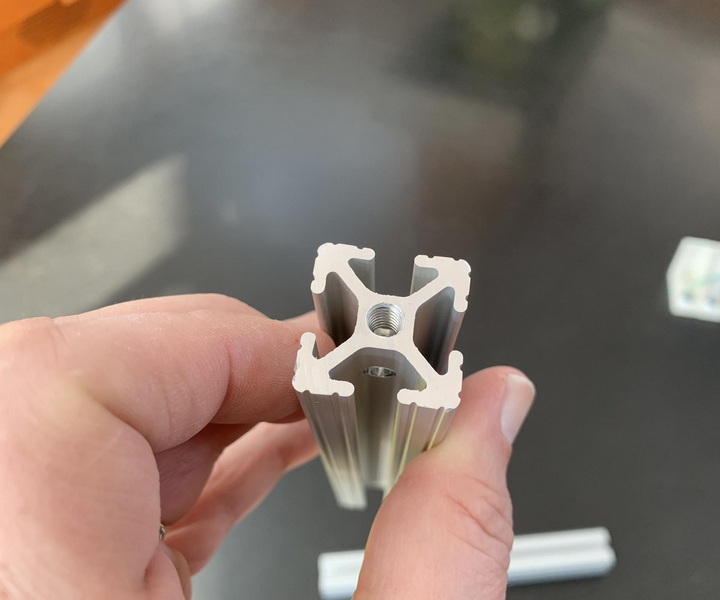

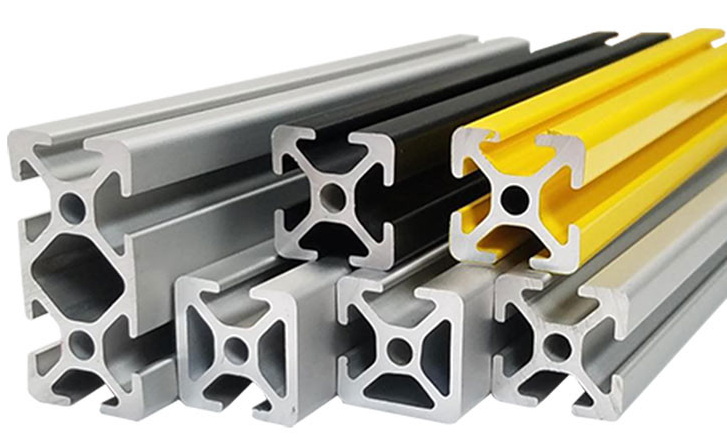

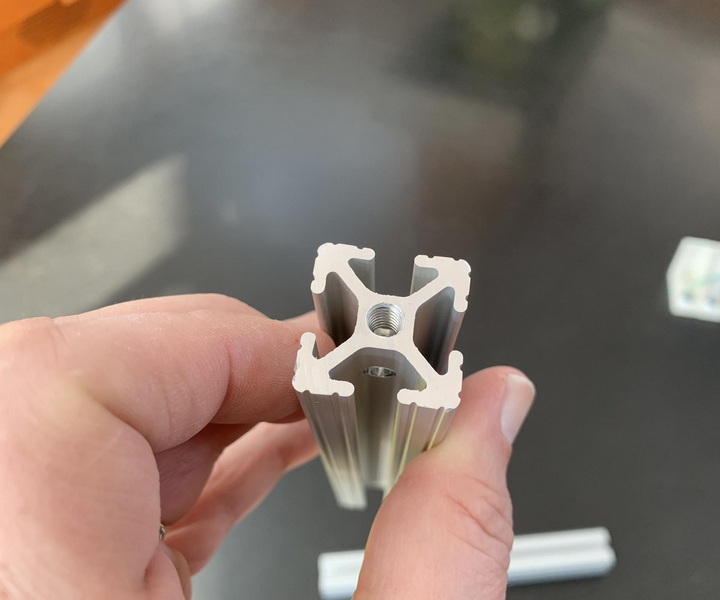

The 2080 aluminum extrusion is a specific type of aluminum profile characterized by its dimensions, which measure 20mm by 80mm. This profile is part of the T-slot aluminum extrusion family, which features a slot along the length of the profile, allowing for easy assembly and modification. The 2080 aluminum extrusion is made from high-quality aluminum alloy, providing excellent strength-to-weight ratios, making it ideal for various applications, including CNC machinery, robotics, and structural frameworks.

Key Features of 2080 Aluminum Extrusion

- Lightweight and Strong: One of the most significant advantages of 2080 aluminum extrusion is its lightweight nature combined with high strength. This makes it an excellent choice for applications where weight is a concern, such as in CNC machines that require precision and stability without adding unnecessary bulk.

- Versatility in Applications: The 2080 aluminum profile is incredibly versatile, making it suitable for a wide range of applications. From building frames for CNC machines to creating custom enclosures and workstations, the possibilities are endless.

- Ease of Assembly: The T-slot design of the 2080 aluminum extrusion allows for quick and easy assembly. Users can connect multiple profiles using standard fasteners, making it simple to create complex structures without the need for specialized tools.

- Cost-Effectiveness: Compared to other materials, aluminum extrusion offers a cost-effective solution for many projects. The ability to create custom lengths and shapes reduces waste and lowers overall material costs.

Key Benefits of 2080 Aluminum Extrusion

Lightweight and Strong

The strength-to-weight ratio of 2080 aluminum extrusion is one of its most appealing features. This profile can support significant loads while remaining lightweight, which is crucial in CNC applications where precision and stability are paramount. The reduced weight also contributes to lower energy consumption in machinery, enhancing overall efficiency.

Versatility in Applications

The versatility of the 2080 aluminum profile makes it a favorite among engineers and designers. It can be used in various applications, including:

- CNC Machinery: The 2080 aluminum extrusion is commonly used to construct frames and supports for CNC machines. Its strength and rigidity ensure that the machine operates smoothly and accurately.

- Robotics: In robotics, the 2080 profile is used to create lightweight yet sturdy frames for robotic arms and other components, allowing for precise movements and operations.

- Custom Projects: DIY enthusiasts and professionals alike appreciate the adaptability of the 2080 aluminum extrusion for custom projects, from furniture to display stands.

Ease of Assembly

One of the standout features of the 2080 aluminum extrusion is its ease of assembly. The T-slot design allows users to connect profiles at various angles, creating complex structures without the need for welding or specialized tools. This flexibility is particularly beneficial in CNC applications, where adjustments and modifications may be necessary.

Cost-Effectiveness

When considering materials for CNC applications, cost is always a factor. The 2080 aluminum extrusion offers a cost-effective solution due to its durability and longevity. Additionally, the ability to create custom lengths and shapes minimizes waste, further reducing costs.

Common Applications of 2080 Aluminum Extrusion

The 2080 aluminum extrusion is used in a variety of applications, showcasing its versatility and effectiveness. Some common uses include:

- CNC Machine Frames: The 2080 profile is ideal for constructing the frames of CNC machines, providing the necessary support and stability for precise operations.

- Workstations: Many manufacturers use 2080 aluminum extrusion to create ergonomic workstations that can be easily adjusted and customized to fit specific needs.

- Enclosures: The profile is often used to build enclosures for electronic components, protecting them from dust and damage while allowing for easy access.

- Automation Systems: In automation, the 2080 aluminum extrusion is used to create frameworks for conveyor systems and robotic arms, ensuring smooth operation and reliability.

Best Practices for Working with 2080 Aluminum Extrusion

To maximize the benefits of 2080 aluminum extrusion in your CNC applications, consider the following best practices:

Measuring and Cutting

Accurate measurements are crucial when working with 2080 aluminum extrusion. Use a reliable measuring tool to ensure precision, and when cutting the profiles, employ a high-quality saw designed for aluminum to achieve clean edges.

Assembly Techniques

When assembling structures with 2080 aluminum extrusion, use T-slot nuts and bolts to secure connections. This method allows for easy adjustments and modifications, making it simple to reconfigure your design as needed.

Finishing Touches

Consider anodizing or powder coating your 2080 aluminum profiles to enhance their appearance and protect against corrosion. These finishes can also improve the durability of the profiles, extending their lifespan in demanding environments.

Regular Maintenance

While aluminum extrusion is generally low-maintenance, regular inspections can help identify any wear or damage. Keeping the profiles clean and free from debris will ensure optimal performance in your CNC applications.

Conclusion

Choosing the right 2080 aluminum profile for your CNC applications can significantly impact the success of your projects. With its lightweight yet strong construction, versatility, ease of assembly, and cost-effectiveness, the 2080 aluminum extrusion is an excellent choice for a wide range of applications. By understanding its features and following best practices for use, you can maximize the benefits of this material in your CNC endeavors.

Related Questions

1. What are the advantages of using 2080 aluminum extrusion over other materials?

The advantages of using 2080 aluminum extrusion include its lightweight nature, high strength-to-weight ratio, versatility in applications, ease of assembly, and cost-effectiveness compared to other materials.

2. Can I use 2080 aluminum extrusion for outdoor applications?

Yes, 2080 aluminum extrusion can be used for outdoor applications, especially if it is anodized or powder-coated to protect against corrosion and environmental factors.

3. How do I cut 2080 aluminum extrusion accurately?

To cut 2080 aluminum extrusion accurately, use a high-quality saw designed for aluminum, and ensure you measure carefully before cutting to achieve clean edges.

4. What tools do I need to assemble structures with 2080 aluminum extrusion?

To assemble structures with 2080 aluminum extrusion, you will need T-slot nuts, bolts, a wrench or screwdriver, and a measuring tool for accurate assembly.

5. Is it possible to customize the length of 2080 aluminum extrusion?

Yes, 2080 aluminum extrusion can be customized to various lengths, allowing you to create the exact dimensions needed for your specific project.