Content Menu

● Understanding Aluminum Extrusions

>> Types of Aluminum Extrusions

>> Applications of 20 x 20 Aluminum Extrusion

● Factors to Consider When Choosing 20 x 20 Aluminum Extrusion

>> 1. Material Grade

>> 2. Finish

>> 3. Length and Quantity

>> 4. Assembly Method

>> 5. Budget

● Assembly Techniques for 20 x 20 Aluminum Extrusion

>> 1. Use the Right Tools

>> 2. Plan Your Design

>> 3. Pre-Drill Holes

>> 4. Use Connectors

>> 5. Check for Squareness

● Maintenance of Aluminum Extrusions

● Conclusion

● Frequently Asked Questions

>> 1. What are the typical costs associated with 20 x 20 aluminum extrusion?

>> 2. How do different finishes affect the longevity of 20 x 20 aluminum extrusion?

>> 3. What are some common design considerations for projects using 20 x 20 aluminum extrusion?

>> 4. Can I cut 20 x 20 aluminum extrusion at home?

>> 5. Are there any specific tools required for assembling 20 x 20 aluminum extrusion?

When embarking on a DIY project, selecting the right materials is crucial to ensure both functionality and aesthetics. One popular choice among DIY enthusiasts is the 20 x 20 aluminum extrusion. This versatile material is used in various applications, from building frames to creating custom furniture. In this article, we will explore how to choose the right 20 x 20 aluminum extrusion for your needs, covering aspects such as types, applications, assembly techniques, and more.

Understanding Aluminum Extrusions

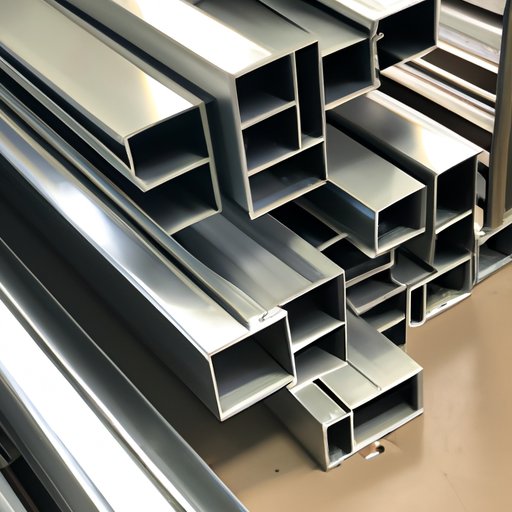

Aluminum extrusion is a process that shapes aluminum alloy into a desired cross-sectional profile. The 20 x 20 aluminum extrusion refers to a specific size, with each side measuring 20 millimeters. This size is particularly popular due to its balance of strength and weight, making it suitable for a wide range of applications.

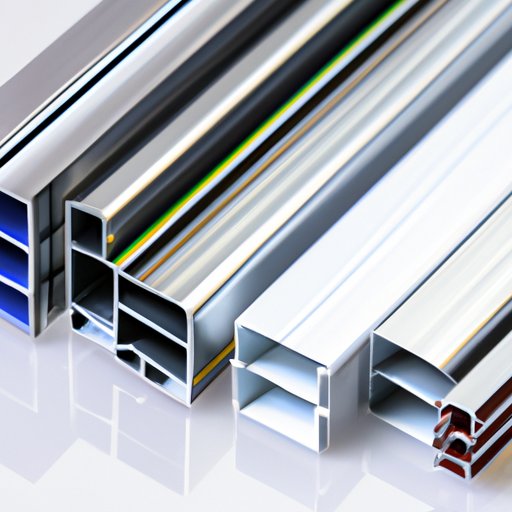

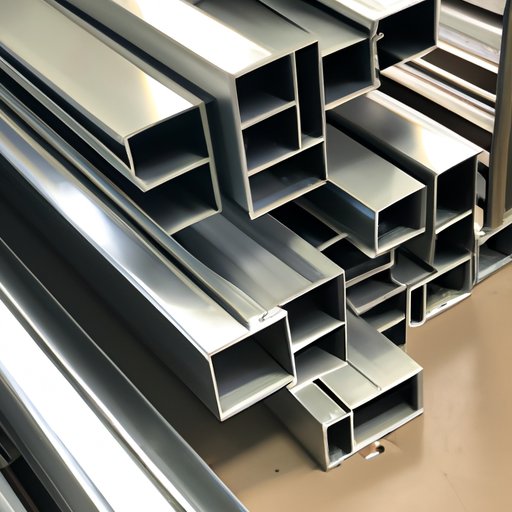

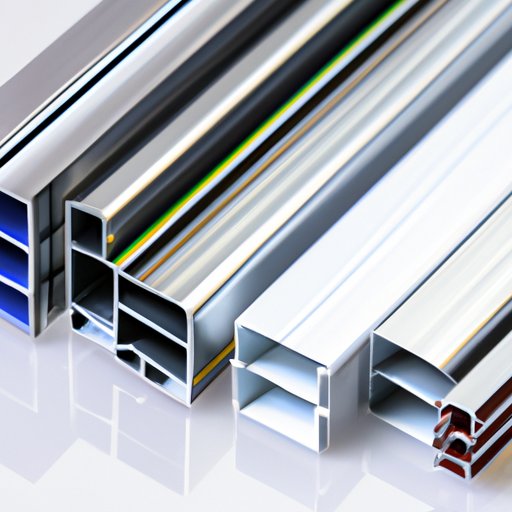

Types of Aluminum Extrusions

There are several types of aluminum extrusions available, each with unique properties and uses:

1. Standard Extrusions: These are the most common types, available in various shapes and sizes. They are typically used for structural applications.

2. Custom Extrusions: If your project requires a specific shape or size that is not available in standard options, custom extrusions can be manufactured to meet your specifications.

3. T-Slot Extrusions: These extrusions feature a T-shaped slot along the length, allowing for easy assembly and connection with other components. T-slot extrusions are particularly popular in modular construction and automation systems.

4. Hollow Extrusions: These are lightweight and provide good structural integrity, making them ideal for applications where weight is a concern.

Applications of 20 x 20 Aluminum Extrusion

The versatility of 20 x 20 aluminum extrusion makes it suitable for various applications, including:

- Frame Construction: Ideal for building frames for machines, furniture, and displays.

- Automated Systems: Commonly used in robotics and automation due to its lightweight and strong properties.

- DIY Projects: Perfect for hobbyists looking to create custom projects, such as shelving units or workstations.

- Architectural Applications: Used in modern architecture for its aesthetic appeal and durability.

Factors to Consider When Choosing 20 x 20 Aluminum Extrusion

When selecting the right 20 x 20 aluminum extrusion for your project, consider the following factors:

1. Material Grade

Aluminum extrusions come in various grades, each offering different properties. Common grades include 6061 and 6063. The 6061 grade is known for its strength and is often used in structural applications, while 6063 is more malleable and is typically used for architectural applications.

2. Finish

The finish of the aluminum extrusion can significantly impact its appearance and durability. Common finishes include:

- Mill Finish: The natural finish of aluminum, which is often used for industrial applications.

- Anodized Finish: A protective layer is added to enhance corrosion resistance and improve aesthetics.

- Powder Coated Finish: A colored finish that provides excellent durability and resistance to scratches and fading.

3. Length and Quantity

Determine the length of the extrusions you need based on your project requirements. Aluminum extrusions are typically sold in standard lengths, but they can also be cut to size. Consider purchasing extra material to account for mistakes or adjustments during assembly.

4. Assembly Method

Consider how you plan to assemble your project. If you are using T-slot extrusions, you will need compatible connectors and fasteners. For standard extrusions, you may require additional brackets or welding for assembly.

5. Budget

Finally, consider your budget. Aluminum extrusions can vary in price based on the grade, finish, and supplier. It's essential to balance quality and cost to ensure you get the best value for your project.

Assembly Techniques for 20 x 20 Aluminum Extrusion

Assembling projects with 20 x 20 aluminum extrusion can be straightforward if you follow the right techniques. Here are some tips to help you get started:

1. Use the Right Tools

Having the right tools is essential for a successful assembly. Common tools include:

- Miter Saw: For cutting extrusions to the desired length.

- Drill: For creating holes for fasteners.

- Wrenches: For tightening bolts and connectors.

2. Plan Your Design

Before starting assembly, create a detailed plan of your project. This should include measurements, a list of materials, and a step-by-step assembly guide. Planning helps prevent mistakes and ensures a smoother assembly process.

3. Pre-Drill Holes

If you are using screws or bolts to connect pieces, pre-drilling holes can make assembly easier and more precise. This step also helps prevent the aluminum from cracking or splitting.

4. Use Connectors

For T-slot extrusions, use appropriate connectors to join pieces together. These connectors are designed to fit snugly into the slots, providing a secure connection without the need for welding.

5. Check for Squareness

As you assemble your project, regularly check for squareness to ensure that everything is aligned correctly. This step is crucial for structural integrity and overall appearance.

Maintenance of Aluminum Extrusions

To ensure the longevity of your aluminum extrusion projects, regular maintenance is essential. Here are some tips:

- Clean Regularly: Use a mild detergent and water to clean the surface of the aluminum. Avoid harsh chemicals that can damage the finish.

- Inspect for Damage: Regularly check for signs of wear or damage, especially in high-stress areas.

- Reapply Finish: If your aluminum extrusion has a protective finish, consider reapplying it as needed to maintain its appearance and durability.

Conclusion

Choosing the right 20 x 20 aluminum extrusion for your DIY project involves understanding the types available, considering your specific needs, and planning your assembly carefully. By taking the time to select the appropriate materials and techniques, you can create a project that is not only functional but also visually appealing.

Frequently Asked Questions

1. What are the typical costs associated with 20 x 20 aluminum extrusion?

The cost of 20 x 20 aluminum extrusion can vary based on the material grade, finish, and supplier. On average, prices range from $5 to $15 per linear foot.

2. How do different finishes affect the longevity of 20 x 20 aluminum extrusion?

Anodized and powder-coated finishes provide enhanced protection against corrosion and wear, significantly extending the lifespan of aluminum extrusions compared to mill finishes.

3. What are some common design considerations for projects using 20 x 20 aluminum extrusion?

When designing with 20 x 20 aluminum extrusion, consider load-bearing requirements, aesthetic preferences, and the intended use of the final product to ensure it meets your needs.

4. Can I cut 20 x 20 aluminum extrusion at home?

Yes, you can cut aluminum extrusion at home using a miter saw or a hacksaw. Ensure you use the appropriate blade designed for cutting metal.

5. Are there any specific tools required for assembling 20 x 20 aluminum extrusion?

Basic tools such as a miter saw, drill, and wrenches are typically sufficient for assembling projects with 20 x 20 aluminum extrusion. Additionally, T-slot connectors may be needed for T-slot extrusions.