Content Menu

● Introduction to 2020 Aluminum Extrusion

● Manufacturing Process and Technical Specifications

● Applications and Industry Usage

● Benefits and Advantages

● Installation and Assembly Guidelines

● Maintenance and Care

● Conclusion

● Frequently Asked Questions

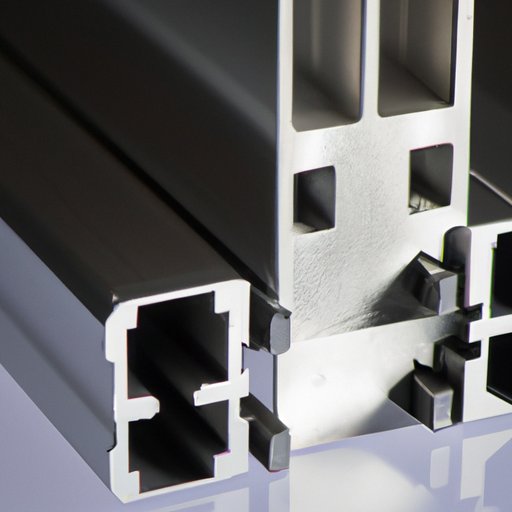

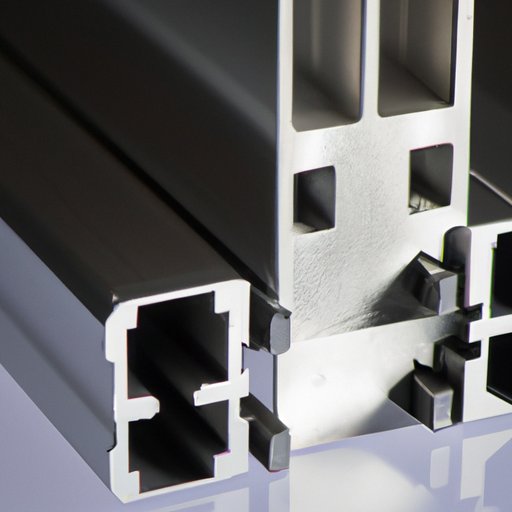

Introduction to 2020 Aluminum Extrusion

The 2020 aluminum extrusion profile represents a cornerstone in modern industrial applications, characterized by its versatile 20mm x 20mm cross-section and exceptional versatility. This standardized profile has become increasingly vital in various industries, from manufacturing automation to architectural applications. The profile's name "2020" refers to its dimensional specifications, with both width and height measuring 20 millimeters, making it an ideal choice for lightweight yet sturdy construction projects. The aluminum extrusion industry has witnessed significant growth, with the global market value reaching $77.8 billion in 2019 and projecting continued expansion through the coming years.

Manufacturing Process and Technical Specifications

The manufacturing process of 2020 aluminum extrusion involves sophisticated techniques that ensure precise dimensional accuracy and structural integrity. The process begins with heating high-quality aluminum billets to approximately 500°C, followed by forcing the heated material through a die that creates the distinctive 2020 profile. The extrusion process incorporates several key features:

- Precise temperature control systems

- Advanced die design technology

- Automated cooling processes

- Quality control measurements

- Surface treatment options

Applications and Industry Usage

The 2020 aluminum extrusion profile finds extensive applications across multiple industries, demonstrating its remarkable versatility and reliability. Key application areas include:

1. Industrial Automation

- Conveyor systems

- Machine guards

- Assembly line frameworks

- Robotic cell enclosures

2. Construction and Architecture

- Display systems

- Partition walls

- Exhibition stands

- Light structural frameworks

3. Furniture and Interior Design

- Modular furniture

- Display cases

- Retail fixtures

- Office partitions

Benefits and Advantages

The 2020 aluminum extrusion profile offers numerous advantages that make it a preferred choice in various applications:

1. Structural Benefits

- Excellent strength-to-weight ratio

- Corrosion resistance

- Thermal conductivity

- Electrical conductivity

2. Design Flexibility

- Easy modification capabilities

- Multiple mounting options

- Compatible with standard accessories

- Modular design possibilities

3. Economic Advantages

- Cost-effective production

- Minimal maintenance requirements

- Long service life

- Recyclability

Installation and Assembly Guidelines

Proper installation and assembly of 2020 aluminum extrusion profiles require attention to detail and adherence to best practices:

1. Pre-Installation Preparation

- Surface cleaning

- Tool preparation

- Component verification

- Layout planning

2. Assembly Techniques

- Proper alignment procedures

- Fastener selection

- Torque specifications

- Connection methods

3. Quality Control Measures

- Dimensional verification

- Structural integrity checks

- Surface finish inspection

- Functionality testing

Maintenance and Care

To ensure optimal performance and longevity of 2020 aluminum extrusion installations, proper maintenance is essential:

1. Regular Inspection

- Visual examination

- Connection verification

- Alignment checks

- Surface condition assessment

2. Cleaning Procedures

- Appropriate cleaning agents

- Cleaning frequency

- Protection methods

- Surface treatment maintenance

3. Preventive Maintenance

- Lubrication requirements

- Component replacement

- Structural reinforcement

- Performance optimization

Conclusion

The 2020 aluminum extrusion profile continues to be a fundamental component in modern industrial and architectural applications. Its versatility, reliability, and cost-effectiveness make it an excellent choice for various projects requiring structural integrity and design flexibility. As the industry continues to evolve, the importance of 2020 aluminum extrusion in manufacturing and construction sectors is expected to grow further.

Frequently Asked Questions

Q1: What are the standard dimensions of 2020 aluminum extrusion?

A: The 2020 aluminum extrusion profile measures 20mm x 20mm in cross-section, making it ideal for lightweight yet sturdy applications.

Q2: What is the weight capacity of 2020 aluminum extrusion?

A: The weight capacity varies depending on the application and span length but typically ranges from 100-150 kg for standard applications when properly supported.

Q3: Can 2020 aluminum extrusion be used outdoors?

A: Yes, with proper surface treatment and protective coating, 2020 aluminum extrusion is suitable for outdoor applications due to its inherent corrosion resistance.

Q4: What are the common connection methods for 2020 profiles?

A: Common connection methods include T-slot nuts, corner brackets, angle brackets, and various specialized connectors designed specifically for 2020 profiles.

Q5: Is 2020 aluminum extrusion recyclable?

A: Yes, aluminum extrusion profiles are 100% recyclable, making them an environmentally friendly choice for construction and manufacturing applications.