Content Menu

● Introduction to Medical Tube Extrusion

● Key Factors in Choosing Medical Tube Plastic Extrusion Machinery Suppliers

● Leading Medical Tube Plastic Extrusion Machinery Suppliers

● Advanced Technology in Medical Tube Extrusion

● Cost Considerations

● Industry Trends and Future Outlook

>> Key Trends:

● Market Analysis

● Conclusion

● Frequently Asked Questions

>> 1. What are the key materials used in medical tube extrusion?

>> 2. What are the regulatory standards for medical tubing extrusion?

>> 3. How does quality control impact medical tubing production?

>> 4. What role does advanced technology play in medical tube extrusion?

>> 5. What factors should be considered when selecting a medical tube extrusion machinery supplier?

Choosing the right medical tube plastic extrusion machinery suppliers is crucial for ensuring the quality, safety, and efficiency of medical tubing production. Medical tubing is used in a variety of applications, including IV lines, catheters, and respiratory tubes, and must meet stringent regulatory standards to ensure biocompatibility and performance. In this article, we will explore the key factors to consider when selecting a supplier and highlight some of the leading manufacturers in the industry.

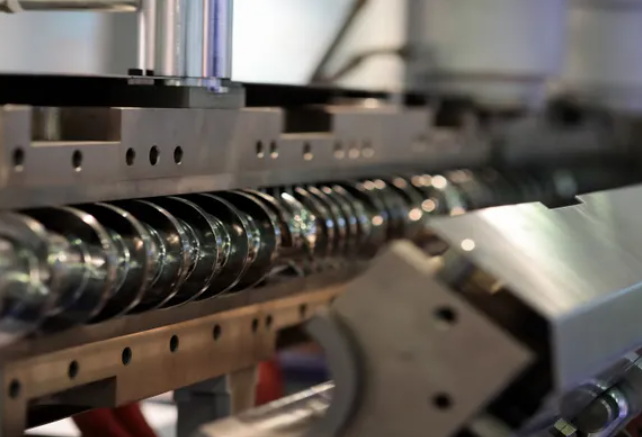

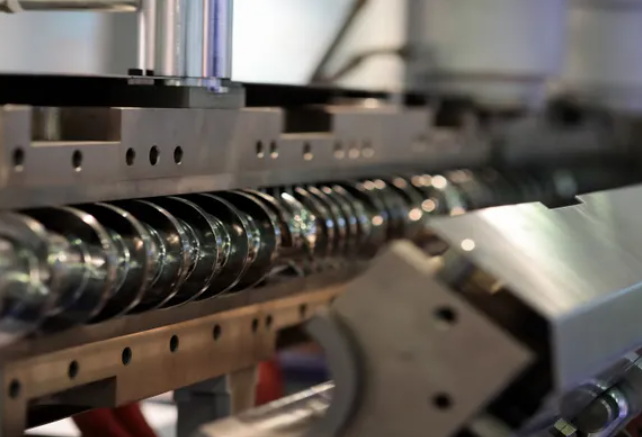

Introduction to Medical Tube Extrusion

Medical tube extrusion involves the process of melting raw materials and shaping them into precise tubes. These tubes must adhere to strict medical standards to ensure durability, flexibility, and compliance with regulatory requirements. The process involves feeding raw materials into an extruder, heating them, and pushing them through a die to achieve the desired shape. The resulting tubes are then cooled and cut to the required lengths.

Key Factors in Choosing Medical Tube Plastic Extrusion Machinery Suppliers

When selecting medical tube plastic extrusion machinery suppliers, several factors should be considered:

1. Experience and Expertise: Look for manufacturers with extensive experience in producing medical-grade tubing. Their expertise ensures that products meet stringent quality standards.

2. Quality Control Measures: Ensure the manufacturer has robust quality control processes in place to monitor and maintain product quality throughout production. This includes raw material inspection, in-process monitoring, dimensional measurement, visual inspection, and functional testing.

3. Material Selection: The manufacturer should offer a range of biocompatible materials suitable for different medical applications, such as PVC, silicone, or polyurethane.

4. Customization Capabilities: The ability to customize tubing to specific requirements is crucial for meeting unique application needs.

5. Regulatory Compliance: Ensure the manufacturer complies with relevant regulations and standards, such as ISO 10993, USP Class VI, FDA 21 CFR Part 820, and EU MDR.

6. Innovation and Technology: Manufacturers that invest in advanced technology and innovation can offer more precise and efficient production processes.

Leading Medical Tube Plastic Extrusion Machinery Suppliers

Several companies are prominent in the medical tube plastic extrusion machinery suppliers industry:

- Compagnie de Saint-Gobain S.A.: Known for its diverse materials and solutions.

- Teleflex Incorporated: Specializes in single-use medical devices.

- Optinova Holding AB: A leading extrusion partner for advanced medical tubing.

- Zeus Industrial Products, Inc.: Offers advanced polymer solutions.

- Duke Extrusion: Provides custom medical tubing solutions with a focus on innovation and quality.

Advanced Technology in Medical Tube Extrusion

Advanced technology plays a significant role in enhancing the quality and efficiency of medical tubing extrusion. Features such as real-time monitoring systems, precision dies, and automated calibration ensure consistent product quality and reduce production variability.

Cost Considerations

Apart from the initial capital outlay, other expenses such as energy usage charges, maintenance fees, and operational overheads over the lifetime of the machinery should also be factored into the overall cost-benefit analysis. Additionally, the cost of raw materials and labor can fluctuate based on market conditions, affecting the overall profitability of the operation.

Industry Trends and Future Outlook

The medical tube plastic extrusion machinery suppliers industry is expected to grow significantly by 2025, driven by increasing demand for medical devices and advancements in technology. Trends include the adoption of sustainable materials, increased use of automation, and a focus on customization to meet specific medical needs.

Key Trends:

- Sustainability: There is a growing emphasis on using environmentally friendly materials and reducing waste in the production process.

- Automation: The integration of AI and robotics is improving efficiency and reducing human error.

- Customization: Manufacturers are focusing on developing tubing solutions tailored to specific medical applications.

Market Analysis

Market analysis indicates that the Asia-Pacific region is expected to be a significant growth area due to its large population and increasing healthcare needs. Additionally, advancements in medical technology and the rise of personalized medicine are driving demand for specialized tubing solutions.

Conclusion

Choosing the best medical tube plastic extrusion machinery suppliers requires careful consideration of several key factors, including experience, quality control, material selection, customization capabilities, regulatory compliance, and innovation. By selecting a reputable supplier, manufacturers can ensure the production of high-quality medical tubing that meets stringent regulatory standards and provides reliable performance in critical medical applications.

Frequently Asked Questions

1. What are the key materials used in medical tube extrusion?

The key materials used in medical tube extrusion include PVC, silicone, polyurethane, and thermoplastic elastomers. These materials are chosen for their biocompatibility, durability, and flexibility.

2. What are the regulatory standards for medical tubing extrusion?

Medical tubing extrusion is subject to various national and international standards, including ISO 10993, USP Class VI, FDA 21 CFR Part 820, and EU MDR. These standards ensure biological safety, material compatibility, and performance under different conditions.

3. How does quality control impact medical tubing production?

Quality control is paramount in medical tubing production. It involves several stages, including raw material inspection, in-process monitoring, dimensional measurement, visual inspection, and functional testing. Each stage ensures that the tubing meets the required specifications and standards.

4. What role does advanced technology play in medical tube extrusion?

Advanced technology enhances the quality and efficiency of medical tubing extrusion by providing features such as real-time monitoring systems, precision dies, and automated calibration. These technologies ensure consistent product quality and reduce production variability.

5. What factors should be considered when selecting a medical tube extrusion machinery supplier?

When selecting a supplier, factors such as experience, quality control measures, material selection, customization capabilities, regulatory compliance, and innovation should be considered. These factors ensure that the supplier can meet the stringent requirements of medical tubing production.