Content Menu

● Introduction to Plastic Sheet Extrusion

>> Applications of Plastic Sheet Extrusion

● Key Considerations for Choosing a Machine

>> 1. Machine Specifications

>> 2. Technology and Features

>> 3. Cost and Return on Investment

● Types of Plastic Extruder Machines

● Factors Affecting the Price of Automatic Plastic Sheet Extrusion Machines

● Cheap Automatic Plastic Sheet Extrusion Machine Price

>> Price Ranges for Different Models

● Conclusion

● Frequently Asked Questions

>> 1. What are the key factors to consider when choosing a plastic sheet extrusion machine?

>> 2. How does the type of plastic material affect the choice of extrusion machine?

>> 3. What are the benefits of using an automatic plastic sheet extrusion machine?

>> 4. How does the production capacity of the machine impact its price?

>> 5. What maintenance tasks are essential for extending the lifespan of a plastic sheet extrusion machine?

● Citations:

Choosing a reliable yet affordable automatic plastic sheet extrusion machine is crucial for businesses looking to optimize their production processes while managing costs effectively. This comprehensive guide will walk you through the key considerations, technical specifications, and cost factors to help you make an informed decision.

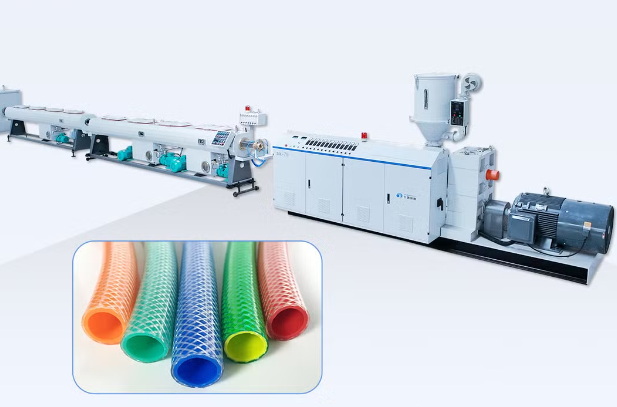

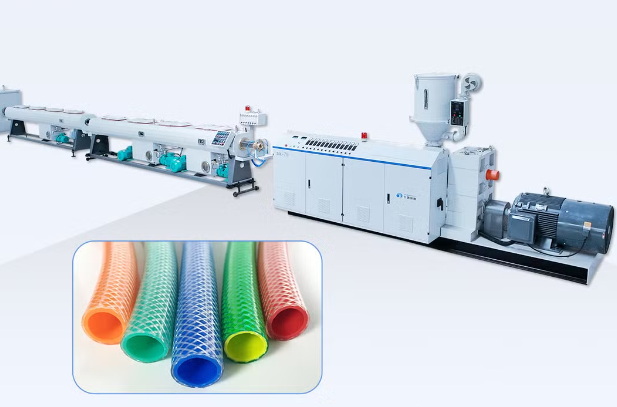

Introduction to Plastic Sheet Extrusion

Plastic sheet extrusion is a process where plastic pellets are melted and formed into continuous sheets. These sheets are widely used in packaging, construction, and automotive industries due to their versatility and durability. The process involves feeding plastic resin into an extruder, where it is melted and mixed by a screw, then passed through a flat die to shape it into a sheet. The sheet is cooled and rolled using chill rolls to achieve the desired thickness and texture[5].

Applications of Plastic Sheet Extrusion

- Packaging: Used for food, pharmaceuticals, and electronics packaging.

- Construction: Panels and insulation materials.

- Automotive: Trim parts and interior components[5].

Key Considerations for Choosing a Machine

1. Machine Specifications

When selecting a cheap automatic plastic sheet extrusion machine, consider the following specifications:

- Extruder Screw Design: A well-designed screw ensures consistent melt and high-quality output. It should be suitable for the type of plastic you plan to process[1].

- Barrel Length and Diameter: Ensure these dimensions match your production needs, affecting output capacity and processing efficiency[1].

- Temperature Control: Precise temperature control systems are crucial for maintaining optimal processing conditions[1].

- Production Capacity: Choose a machine with the appropriate capacity for your production volume, measured in kilograms per hour[1].

- Sheet Thickness Range: Ensure the machine can produce sheets within the desired thickness range for your applications[1].

2. Technology and Features

- Automation: Advanced automation features improve precision and reduce manual intervention. Look for machines with automatic sheet thickness control[1].

- Control System: Opt for user-friendly control panels or touchscreen interfaces for ease of operation and programmable settings[1].

- Energy Efficiency: Consider machines with energy-efficient designs to reduce operational costs and environmental impact[1].

- Cooling System: Ensure the machine has an efficient cooling system to quickly and evenly cool the plastic sheets during production[1].

- Safety Features: Verify that the machine is equipped with necessary safety features, such as emergency stop buttons and safety guards[1].

3. Cost and Return on Investment

- Initial Cost: Compare the initial cost of the machine with your budget, considering long-term benefits and performance[1].

- Operational Costs: Assess the machine's energy consumption, maintenance needs, and potential downtime costs to evaluate its overall cost-effectiveness[1].

- Return on Investment (ROI): Calculate the expected ROI based on production efficiency, quality of output, and cost savings over time[1].

- Supplier Reputation: Choose a machine from a supplier with a good reputation for customer service and support to ensure a smooth purchasing experience[1].

- Financing Options: Explore financing or leasing options if the upfront cost is a concern, making the investment more manageable[1].

Types of Plastic Extruder Machines

Understanding the different types of plastic extruder machines can help you choose the right one for your needs:

- Single-Screw Extruders: The most widely used, known for simplicity and cost-effectiveness. Ideal for producing sheets, films, and pipes[2].

- Twin-Screw Extruders: Feature two intermeshing screws, suitable for complex formulations and uniformity in material processing[2].

- Ram Extruders: Less common, used for specific applications requiring high pressure[2].

Factors Affecting the Price of Automatic Plastic Sheet Extrusion Machines

The price of these machines varies based on several factors:

- Machine Type: Different machines are designed for specific applications, impacting their price[7].

- Production Capacity: Higher capacity machines are generally more expensive[7].

- Components and Technology: Advanced features like automation and energy-efficient motors increase the cost[7].

- Material Handling: Machines capable of handling diverse materials are typically more expensive[12].

Cheap Automatic Plastic Sheet Extrusion Machine Price

Prices for basic models can start from approximately $8,000 to $11,000 USD, while advanced models range from $30,000 to $120,000 USD or more, depending on features and capacity[5][7].

Price Ranges for Different Models

- Basic Models: ₹ 6,80,000 to ₹ 9,50,000 (approximately $8,000 to $11,000 USD)[5].

- Advanced Models: ₹ 25,00,000 to ₹ 98,50,000 (approximately $30,000 to $120,000 USD)[5].

- High-End Models: Up to $200,000 or more for complex configurations[5].

Conclusion

Choosing a reliable yet cheap automatic plastic sheet extrusion machine involves careful consideration of machine specifications, technology, cost, and supplier reputation. By focusing on these factors, businesses can select a machine that meets their production requirements while providing long-term value.

Frequently Asked Questions

1. What are the key factors to consider when choosing a plastic sheet extrusion machine?

When selecting a plastic sheet extrusion machine, consider machine specifications (screw design, barrel dimensions, temperature control), production capacity, automation features, energy efficiency, and cost factors (initial cost, operational costs, ROI)[1].

2. How does the type of plastic material affect the choice of extrusion machine?

Different machines are designed to handle specific types of plastics. The material's thermal stability, viscosity, and filler content influence the choice of machine to ensure optimal performance and product quality[2].

3. What are the benefits of using an automatic plastic sheet extrusion machine?

Automatic machines offer high-speed production, consistent quality, reduced labor costs, energy efficiency, and the ability to handle a variety of materials. They also minimize waste and support sustainable manufacturing practices[9].

4. How does the production capacity of the machine impact its price?

Higher production capacity machines are generally more expensive due to their larger size and more complex design, which can handle higher volumes of plastic material[7].

5. What maintenance tasks are essential for extending the lifespan of a plastic sheet extrusion machine?

Regular maintenance includes inspecting drive components, checking hydraulic and electrical systems, cleaning equipment, inspecting molds, lubricating components, and ensuring proper control system functionality[11].

Citations:

[1] https://www.cnchaoxu.com/news-center/how-to-choose-a-good-plastic-sheet-extruder-machine

[2] https://abhiplastics.com/the-ultimate-guide-to-choosing-the-right-plastic-extruder-machine-for-your-industrial-needs/

[3] https://www.alamy.com/stock-photo/extrusion-machine.html

[4] https://www.youtube.com/watch?v=lh4edjYWzqg

[5] https://www.yjing-extrusion.com/where-to-find-the-best-deals-on-automatic-plastic-sheet-extrusion-machines.html

[6] https://www.yeshaengineering.com/sheet-extrusion-line.html

[7] https://deltaplastik.com/blog/plastic-extrusion-machine-prices-2024-choosing-the-right-machine-for-your-needs

[8] https://www.made-in-china.com/products-search/hot-china-products/Plastic_Sheet_Extrusion_Machine.html

[9] https://www.yjing-extrusion.com/what-are-the-benefits-of-using-an-automatic-plastic-sheet-extrusion-machine.html

[10] https://jieyatwinscrew.com/blog/everything-you-need-to-know-about-plastic-sheet-extrusion/

[11] https://tz-machinery.com/sheet-extruder-applications-and-maintenance-guide/

[12] https://www.yjing-extrusion.com/what-factors-affect-the-price-of-an-automatic-plastic-extrusion-machine.html

[13] https://www.tradeindia.com/manufacturers/plastic-sheet-extrusion-machine.html

[14] https://www.stlongsheng.com/News_dt/1867816880525758464.html

[15] https://www.tgtextrusion.com/news/a-buyers-guide-to-selecting-the-best-plastic-strap-machine/

[16] https://www.cowinextrusion.com/key-points-to-pay-attention-to-when-selecting-plastic-extruder/

[17] https://www.stlongsheng.com/News_dt/85.html

[18] https://www.cowinextrusion.com/all-about-plastic-extrusion-and-helpful-tips-for-buying-extruder-machinery/

[19] https://paulmurphyplastics.com/industry-news-blog/3-tips-you-should-consider-when-choosing-a-plastic-extrusion-machine/

[20] https://www.alibaba.com/showroom/plastic-sheet-extrusion-machine.html

[21] https://www.plasticstoday.com/extrusion-pipe-profile/tips-for-buying-a-new-or-not-so-new-extrusion-line

[22] https://www.cowellextrusion.com/everything-you-need-to-know-about-sheet-extrusion-a-comprehensive-guide/

[23] https://stdcdesigner.en.made-in-china.com/product/gEvUuWcSHLYB/China-Fully-Automatic-Plastic-Sheet-Extrusion-Machine-for-PP-PS-PE.html

[24] https://www.chyiyang.com/guide-to-blown-film-extrusion-machines

[25] https://stock.adobe.com/search?k=plastic+extrusion+machine

[26] https://www.shutterstock.com/search/plastic-extrusion-machine

[27] https://www.shutterstock.com/search/extrusion-machine-plastic

[28] https://www.istockphoto.com/photos/extruder-machine

[29] https://www.youtube.com/playlist?list=PL8B1r8zT-52EYf149q_TDvFNg0-lzLsYA