Content Menu

● Introduction to Extrusion Blow Molding

>> Extrusion Blow Molding Process Overview

● Key Factors to Consider

>> Machine Type and Technology

>> Production Capacity and Output

>> Machine Size and Footprint

>> Cost and Budget

>> Advanced Features and Automation

● Choosing a Reliable Manufacturer

>> Examples of Reliable Manufacturers

● Features of a Cheap 30L Automatic Extrusion Blow Molding Machine

>> Example Specifications

● Troubleshooting Common Issues

● Conclusion

● FAQ

>> 1. What are the main types of blow molding machines?

>> 2. How do I choose the right blow molding machine?

>> 3. What materials can be used in blow molding?

>> 4. What are the benefits of a fully automatic extrusion blow molding machine?

>> 5. How can I troubleshoot common issues in extrusion blow molding?

● Citations:

Choosing a reliable yet affordable 30L automatic extrusion blow molding machine involves several key considerations. This article will guide you through the process, highlighting important factors such as machine type, production capacity, cost, and technology.

Introduction to Extrusion Blow Molding

Extrusion blow molding is a widely used process for producing hollow plastic products like bottles, containers, and drums. It is particularly suitable for large-scale production due to its efficiency and cost-effectiveness. The process involves extruding a parison (a tube-like piece of plastic) into a mold, where it is then inflated with air to take the shape of the mold cavity.

Extrusion Blow Molding Process Overview

1. Extrusion: The plastic material is melted and formed into a parison.

2. Molding: The parison is placed into a mold and inflated with air.

3. Cooling: The plastic cools and solidifies, taking the shape of the mold.

4. Ejection: The mold opens, and the finished product is removed.

Key Factors to Consider

When selecting a cheap 30L automatic extrusion blow molding machine, consider the following factors:

Machine Type and Technology

- Extrusion Blow Molding Machines: Ideal for medium to large containers.

- Injection Blow Molding Machines: Suitable for small, precise products.

- Stretch Blow Molding Machines: Commonly used for PET bottles.

Production Capacity and Output

- Cycle Time: How quickly the machine can produce one unit.

- Mold Size: Determines the size of the product.

- Machine Speed: Affects overall production volume.

Machine Size and Footprint

Ensure the machine fits your production space and layout.

Cost and Budget

- Initial Investment: Purchase price of the machine.

- Operating Expenses: Energy consumption, maintenance costs.

- Maintenance Costs: Regular upkeep and repair expenses.

Advanced Features and Automation

- Energy Efficiency: Saves on operational costs.

- User-Friendly Controls: Enhances productivity and reduces downtime.

Choosing a Reliable Manufacturer

A reliable manufacturer should offer:

- Competitive Pricing: Offers a cheap 30L automatic extrusion blow molding machine without compromising quality.

- Professional After-Sales Service: Ensures support and maintenance are readily available.

- Advanced Technology: Incorporates features like automation and energy efficiency.

Examples of Reliable Manufacturers

- MEPER: Known for competitive pricing and high-quality machines.

- Tongda Machinery: Offers fully automatic machines with advanced features.

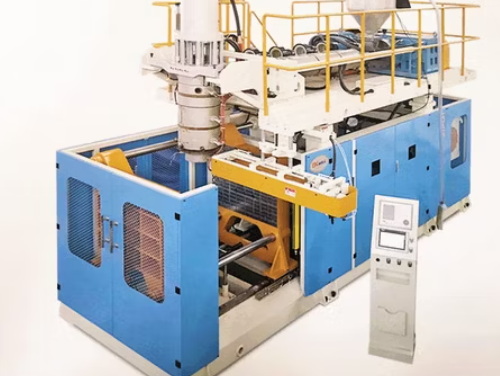

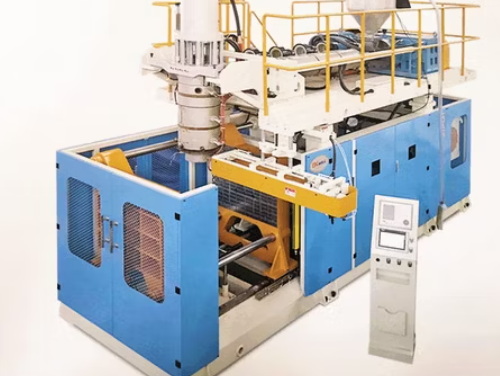

Features of a Cheap 30L Automatic Extrusion Blow Molding Machine

A cheap 30L automatic extrusion blow molding machine should include:

- PLC Control System: For easy operation and automation.

- Automatic Malfunction Alarm: Self-diagnosis for efficient troubleshooting.

- Imported Hydraulic Components: Enhances durability and performance.

- Deflashing Function: Reduces post-processing time.

Example Specifications

| Feature | Description |

| Material | PE, PP |

| Max Container Capacity | 30L |

| Output (Dry Cycle) | 400 pcs/hr |

| Machine Dimensions | 4.52.53.0 M |

| Power Consumption | 42 KW |

Troubleshooting Common Issues

Common issues in extrusion blow molding include:

- Melt Temperature Too High: Adjust temperature settings.

- Blowing Gas Shortage: Check air supply lines and mold vents.

- Product Burst: Increase clamping force or use stronger resin.

Conclusion

Choosing a reliable yet cheap 30L automatic extrusion blow molding machine requires careful consideration of machine type, production capacity, cost, and technology. By focusing on these factors and selecting a reputable manufacturer, you can ensure efficient and cost-effective production of high-quality plastic products.

FAQ

1. What are the main types of blow molding machines?

- Extrusion Blow Molding (EBM): Ideal for medium to large containers.

- Injection Blow Molding (IBM): Used for small, precise products.

- Stretch Blow Molding (SBM): Commonly used for PET bottles.

2. How do I choose the right blow molding machine?

- Consider factors like machine type, production capacity, size, cost, and technology.

- Ensure compatibility with your plastic material and product design.

3. What materials can be used in blow molding?

- Common materials include PE, PP, PVC, and PET.

- Some machines can handle co-extrusion with barrier resins like EVOH.

4. What are the benefits of a fully automatic extrusion blow molding machine?

- Offers high automation, reducing labor costs and increasing efficiency.

- Features like PLC control and automatic malfunction alarms enhance productivity.

5. How can I troubleshoot common issues in extrusion blow molding?

- Check melt temperature, air supply, and mold vents for common issues.

- Refer to a comprehensive troubleshooting guide for detailed solutions.

Citations:

[1] https://www.meper-blowmolding.com/extrusion-blow-molding-machine/

[2] https://www.sunray-machine.com/product/1030l-plastic-jerry-can-extrusion-blow-molding-machine.html

[3] https://www.moldingmachinetepai.com/news/how-to-select-a-blow-molding-machine.html

[4] https://www.ostarmachine.com/product-38.html

[5] https://www.tongdamachine.net/video/

[6] https://www.china-leshan.com/m/index.php?m=content&c=index&a=show&catid=184&id=401

[7] https://www.chinaplastictech.com/extrusion-blow-molding-failures-and-remedies.html/

[8] https://www.youlizn.com/news/blow-molding-machine-frequently-asked-questions.html

[9] https://www.meper-blowmolding.com/best-blow-molding-machine-in-the-uk/

[10] https://cntongdajx.en.made-in-china.com/product/DMkEljgrgpIh/China-Tongda-Htll-30L-Fully-Automatic-Plastic-Extrusion-Blow-Molding-Machine-High-Quality-Cheap-Price.html

[11] https://www.tongdamachine.net/choose-right-extrusion-blow-molding-machine/

[12] https://dawson-plastic.en.made-in-china.com/product/qyGQoNPCnIkf/China-30L-HDPE-Jerry-Cans-Automatic-Extrusion-Blow-Molding-Machine-Toggle-Type-Blow-Machine.html

[13] https://www.qenos.com/internet/home.nsf/web/RHAT-96ETFY

[14] https://www.wangbrand.com/en/faq_10.htm

[15] https://www.tech-long.com/a-how-to-choose-blow-molding-machine.html

[16] https://news.technepackaging.com/en/blow-molding-key-aspects

[17] https://www.meper-blowmolding.com/blow-molding-machine-price/

[18] https://www.linkedin.com/pulse/path-perfection-unveiling-secrets-selecting-ideal-blow-jaiswal

[19] https://www.bottleblowmolding.com/How-to-choose-extrusion-blow-molding-machine-for-20L-30L-HDPE-drum-production-id41666737.html

[20] https://www.alibaba.com/product-detail/30L-Factory-Price-Automatic-Extrusion-blow_1600700720190.html

[21] https://www.linkedin.com/pulse/7-important-factors-consider-when-choosing-b9klc

[22] https://www.alibaba.com/product-detail/Automatic-High-Speed-Small-Plastic-1_60790423749.html

[23] https://gsblowing.com/blow-molding-machine-buying-guide/

[24] https://cmppin.com/blog/how-to-select-a-blow-moulding-machine/

[25] https://maiqiang-machine.en.made-in-china.com/product/kXomBKtykZph/China-Fully-Automatic-Stretch-Blow-Molding-Machine-with-Cheapest-Price.html