Content Menu

● Understanding Your Production Needs

● Key Factors to Consider When Choosing a Manufacturer

● Evaluating Manufacturer Profiles

● Comparing Costs

● Visiting Manufacturing Facilities

● Conclusion

● FAQ

>> 1. What are the key components of a PVC pipe extrusion line?

>> 2. How do I determine the right size of PVC pipes for my production line?

>> 3. What certifications should I look for in a PVC pipe extrusion line?

>> 4. How important is after-sales support when choosing a manufacturer?

>> 5. Can I customize my PVC pipe extrusion line?

● Citations:

Choosing the right manufacturer for a PVC pipe extrusion line is crucial for ensuring the quality and efficiency of your production process. With numerous manufacturers in China, it can be overwhelming to select a reliable one. This guide will help you navigate through the essential factors to consider when choosing a PVC pipe extrusion line manufacturer in China.

Understanding Your Production Needs

Before you start looking for manufacturers, it's vital to assess your specific production requirements:

Production Capacity

- Determine the output capacity you need based on your market demand.

- Consider the size and type of PVC pipes you intend to produce.

Pipe Specifications

- Identify the diameter, wall thickness, and length of pipes you need.

- Different applications may require different specifications.

Key Factors to Consider When Choosing a Manufacturer

When evaluating potential manufacturers, consider the following critical factors:

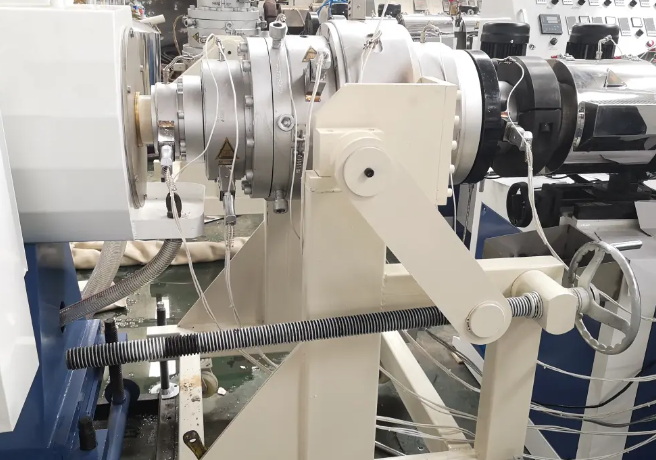

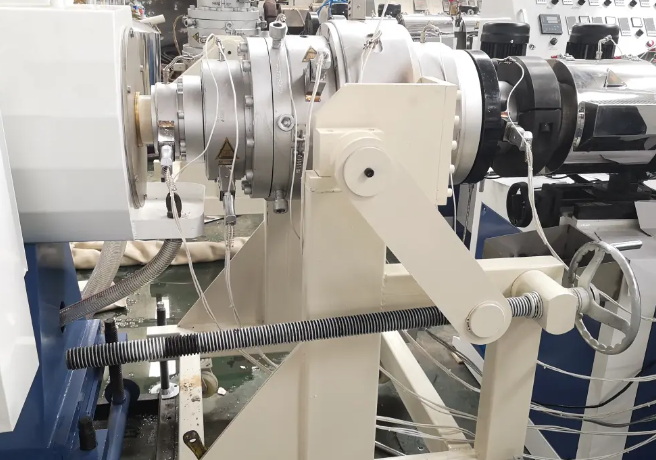

1. Quality of Equipment

- Look for manufacturers that use high-quality materials in their extrusion lines.

- Ensure that the machines comply with international standards such as CE and ISO certifications.

2. Technology and Automation

- Modern extrusion lines are equipped with advanced control systems and automation features.

- PLC controls and user-friendly interfaces can enhance precision and reduce human error.

3. Customization Options

- Choose a manufacturer that offers customization options to meet your specific production needs.

- The ability to adjust parameters like pipe dimensions and material compatibility is crucial.

4. After-Sales Support

- Reliable after-sales support is essential for maintaining production efficiency.

- Check if the manufacturer offers training programs, technical support, and easy access to spare parts.

5. Reputation and Experience

- Research the manufacturer's reputation in the industry.

- Look for customer reviews and testimonials to gauge reliability and quality.

Evaluating Manufacturer Profiles

Once you have identified potential manufacturers, evaluate their profiles:

1. Company History

- Investigate how long the manufacturer has been in business.

- A company with extensive experience is likely to have better expertise in producing reliable equipment.

2. Product Range

- Assess the variety of PVC pipe extrusion lines they offer.

- A diverse product range indicates a manufacturer's capability to cater to different needs.

Comparing Costs

While cost should not be the only deciding factor, it's essential to consider:

1. Initial Investment

- Evaluate the upfront costs of purchasing an extrusion line.

- Higher initial investments may lead to better long-term returns through reduced downtime and maintenance costs.

2. Operational Efficiency

- Consider energy consumption and operational costs associated with running the equipment.

- Efficient machines can significantly lower your overall production costs.

Visiting Manufacturing Facilities

If possible, visiting manufacturing facilities can provide valuable insights:

- Observe the production process and quality control measures in place.

- Engaging directly with staff can help assess their expertise and willingness to support your needs.

Conclusion

Choosing a reliable PVC pipe extrusion line manufacturer in China requires careful consideration of various factors including production needs, equipment quality, technology, after-sales support, reputation, and cost. By thoroughly evaluating potential manufacturers based on these criteria, you can make an informed decision that aligns with your production goals.

FAQ

1. What are the key components of a PVC pipe extrusion line?

The key components include a twin-screw extruder, molds, vacuum calibration tanks, haul-off units, cutting machines, and stackers.

2. How do I determine the right size of PVC pipes for my production line?

Assess your market demand and application requirements to determine the appropriate diameter and wall thickness for your pipes.

3. What certifications should I look for in a PVC pipe extrusion line?

Look for CE and ISO certifications which indicate compliance with international safety and quality standards.

4. How important is after-sales support when choosing a manufacturer?

After-sales support is crucial as it ensures that any issues are promptly addressed, minimizing downtime in your production process.

5. Can I customize my PVC pipe extrusion line?

Yes, many manufacturers offer customization options to cater to specific production requirements such as pipe dimensions and material types.

Citations:

[1] https://www.twinscrew.net/en/article/How-to-Choose-the-Best-PVC-Pipe-Extrusion-Line.html

[2] https://trustymachine.en.made-in-china.com/product-group/selJPCyrHpUt/PVC-Pipe-Extrusion-line-1.html

[3] https://www.faygo.cn/Pipe-Extrusion-System/286.html

[4] https://www.youtube.com/watch?v=G2CKNMGFI3Q

[5] https://www.twinscrew.net/en/article/PVC-Pelletizing-Extrusion-Line-Guide.html

[6] https://qsplasticmachine.en.made-in-china.com/product-group/toqGMvebfgUd/Plastic-Pipe-Extrusion-Line-catalog-1.html

[7] https://www.linkedin.com/pulse/10-frq-pipe-extruder-line-megan-jwell-jwell-machinery-

[8] https://www.jwellextrusions.com/selecting-the-right-pipe-extruder.html

[9] https://www.blesson.cn/faqs/