Content Menu

● Understanding the Aluminum Extrusion Process

● Tools and Equipment Needed

● Step-by-Step Guide to Changing a Die

>> Step 1: Preparation

>> Step 2: Remove Existing Die

>> Step 3: Install New Die

>> Step 4: Testing

● Best Practices for Die Changes

● The Role of Extrusion Dies and Tooling

>> Types of Extrusion Dies

● Design Considerations for Extrusion Dies

● Maintenance of Aluminum Extrusion Dies

● Conclusion

● FAQ

>> 1. What types of dies are used in aluminum extrusion?

>> 2. How often should dies be changed?

>> 3. What safety precautions should be taken during a die change?

>> 4. Can I change a die alone?

>> 5. What should I do if I encounter issues during installation?

● Citations:

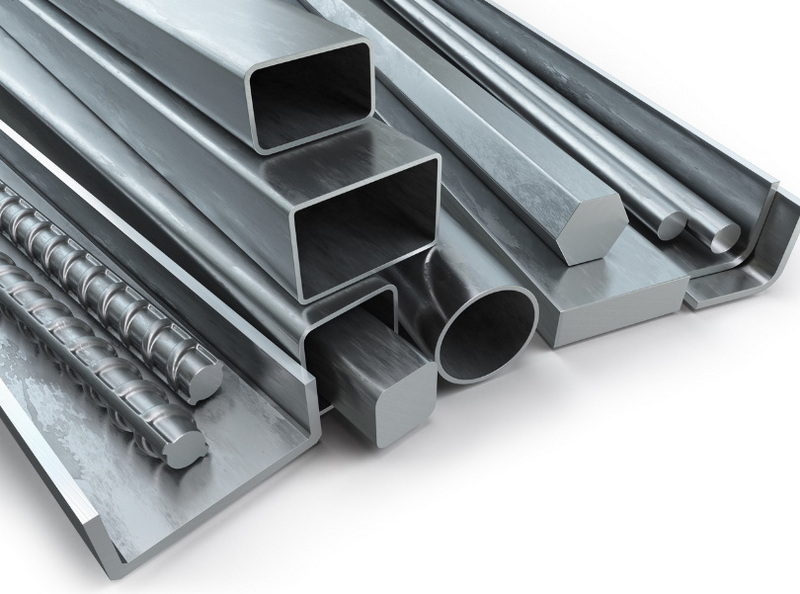

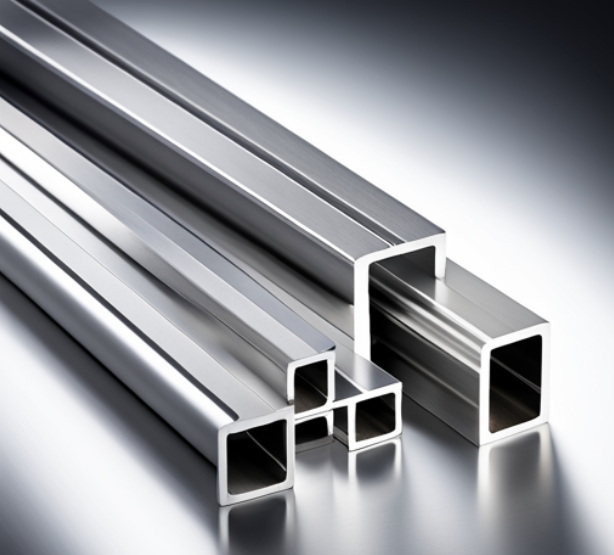

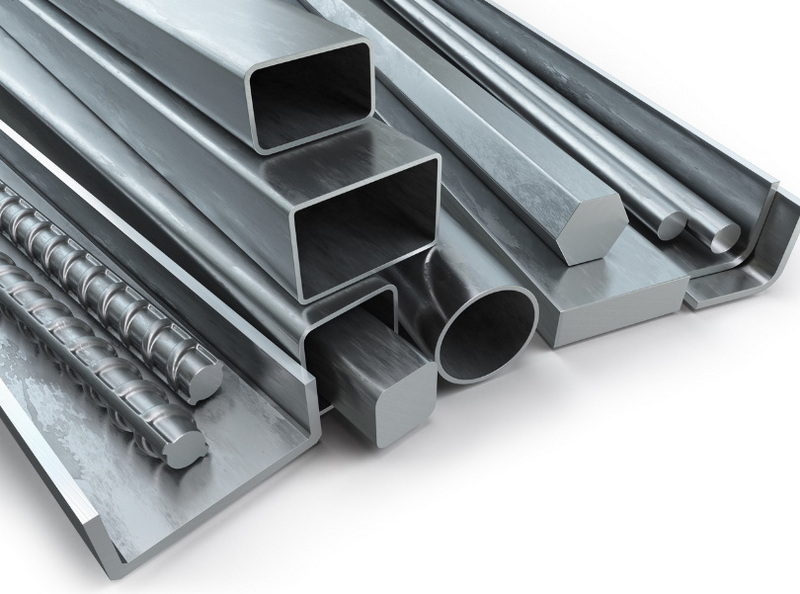

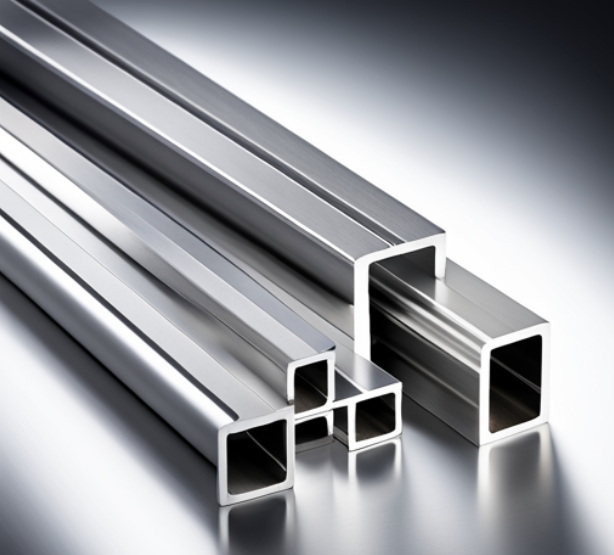

Aluminum extrusion is a vital manufacturing process that shapes aluminum into desired profiles by forcing it through a die. Changing the die on an aluminum extrusion press is a critical operation that requires precision and careful handling to ensure efficiency and product quality. This article provides a comprehensive guide on how to change a die on an aluminum extrusion press, detailing the necessary steps, tools, and considerations involved in the process.

Understanding the Aluminum Extrusion Process

Before delving into the die-changing procedure, it is essential to understand the aluminum extrusion process itself. The basic steps include:

- Die Preparation: The die must be designed and machined to create the desired cross-sectional shape of the aluminum profile.

- Billet Preheating: The aluminum billet is preheated to enhance its malleability.

- Extrusion: The heated billet is forced through the die under high pressure, resulting in the formation of the desired profile.

- Post-Extrusion Handling: After exiting the die, the extruded material undergoes cooling, stretching, cutting, and inspection.

Tools and Equipment Needed

Changing a die on an aluminum extrusion press requires specific tools and equipment:

- Wrenches and Socket Sets: For loosening and tightening bolts.

- Hoist or Crane: To lift heavy dies safely.

- Die Cart: For transporting dies to and from the press.

- Lubricants: To facilitate easy removal and installation of dies.

- Safety Gear: Including gloves, goggles, and steel-toed boots for protection.

Step-by-Step Guide to Changing a Die

Step 1: Preparation

Before beginning the die change, ensure that you have all necessary tools and safety equipment ready.

1. Shut Down the Press: Follow proper shutdown procedures to ensure that the machine is not operational during the die change.

2. Cool Down: Allow the press to cool down if it has been in operation to avoid burns or injuries.

3. Clean Work Area: Clear any debris or materials from around the press to create a safe working environment.

Step 2: Remove Existing Die

1. Loosen Bolts: Use wrenches or socket sets to loosen all bolts securing the existing die in place.

2. Lift Die Out: With assistance from a hoist or crane, carefully lift the old die out of the press. Ensure that all personnel are clear of the lifting path.

3. Inspect Die: Check for wear or damage on the removed die before storing it properly for future use.

Step 3: Install New Die

1. Prepare New Die: Inspect the new die for any defects or damage before installation. Clean it thoroughly if necessary.

2. Position Die in Press: Using a hoist or crane, carefully position the new die into place within the extrusion press.

3. Secure Die: Tighten all bolts securely using wrenches or socket sets. Ensure that the die is aligned correctly according to manufacturer specifications.

4. Apply Lubricant: Apply lubricant to any moving parts associated with the die to facilitate smooth operation.

Step 4: Testing

1. Power Up Press: Turn on the extrusion press following proper startup procedures.

2. Run Test Extrusion: Conduct a test run with scrap material to ensure that everything is functioning correctly and that there are no leaks or misalignments.

3. Inspect Output: Examine the extruded profile for quality and consistency. Make adjustments as necessary based on test results.

Best Practices for Die Changes

- Always follow manufacturer guidelines for both equipment operation and die maintenance.

- Regularly inspect dies for wear and tear to prevent unexpected failures during production.

- Maintain proper alignment during installation to ensure consistent product quality.

- Keep detailed records of die usage and maintenance schedules for optimal performance tracking.

The Role of Extrusion Dies and Tooling

The aluminum extrusion process relies heavily on precision-engineered dies that shape aluminum into specific profiles. These dies are critical components that directly influence product quality and manufacturing efficiency.

Types of Extrusion Dies

- Solid Dies: Used for creating solid profiles without voids.

- Hollow Dies: Designed for profiles with one or more voids, such as bridge or spider shapes.

- Semi-Hollow Dies: For profiles with partially enclosed voids, allowing for complex shapes.

Design Considerations for Extrusion Dies

When designing dies, several factors must be considered:

- Effective Bearing Length: This governs metal flow through the die, ensuring uniform exit speeds across different profile sections.

- Thermal Management: Proper cooling systems must be integrated into dies to prevent overheating and ensure consistent material flow.

- Finite Element Analysis (FEA): Utilizing FEA simulations helps predict potential issues related to material flow and structural integrity before manufacturing dies.

Maintenance of Aluminum Extrusion Dies

Proper maintenance of extrusion dies is essential for maximizing their lifespan and ensuring consistent production quality:

1. Regular Inspections: Inspect dies after each production run for signs of wear or damage.

2. Cleaning Protocols: Thoroughly clean dies to remove any buildup that could affect performance.

3. Lubrication Techniques: Use appropriate lubricants in high-stress areas to minimize friction and heat buildup.

4. Temperature Monitoring: Keep track of temperature variations during production as excessive heat can lead to premature wear.

5. Alignment Checks: Regularly verify that dies are correctly aligned within presses to avoid dimensional inaccuracies in extrusions.

Conclusion

Changing a die on an aluminum extrusion press is a crucial task that requires attention to detail, safety precautions, and adherence to best practices. By following this comprehensive guide, operators can ensure efficient operations while maintaining high-quality standards in their extruded products. Proper maintenance of both dies and presses will further enhance productivity and reduce downtime in manufacturing processes.

FAQ

1. What types of dies are used in aluminum extrusion?

Aluminum extrusion uses various types of dies, including solid dies for simple profiles and complex dies with mandrels for hollow shapes.

2. How often should dies be changed?

The frequency of changing dies depends on production volume and wear; typically, they should be inspected after every production run for signs of wear.

3. What safety precautions should be taken during a die change?

Operators should wear appropriate safety gear, ensure proper machine shutdown procedures are followed, and keep work areas clear of hazards.

4. Can I change a die alone?

While it may be possible for small dies, it is recommended to have assistance when changing larger dies due to their weight and size.

5. What should I do if I encounter issues during installation?

If issues arise during installation, consult equipment manuals or contact technical support for guidance before proceeding further.

Citations:

[1] https://americandouglasmetals.com/2024/05/19/understanding-the-aluminum-extrusion-process/

[2] https://geminigroup.net/understanding-aluminum-extrusion-dies/

[3] https://aec.org/extrusion-die-process-application

[4] https://bonnellaluminum.com/tech-info-resources/aluminum-extrusion-process/

[5] https://www.linkedin.com/pulse/ten-tips-improve-aluminum-extrusion-die-working-efficiency-abel-tsao

[6] https://www.yjing-extrusion.com/what-are-the-best-practices-for-aluminum-extrusion-design.html

[7] https://www.linkedin.com/pulse/die-correction-notes-aluminum-extrusion-abel-tsao

[8] https://www.eps-aluminum.com/Maintaining-Aluminum-Extrusion-Dies-A-Guide-for-Successful-Operations-id67287697.html

[9] https://www.outashi.com/blog/the-best-design-practices-for-aluminum-extrusions-id38.html

[10] https://satimaco.wixsite.com/satimaco/post/aluminum-extrusion-machine-maintenance-tips-for-peak-performance