Content Menu

● Introduction

● Understanding 80/20 Aluminum Extrusion

● Benefits of Using 80/20 Aluminum Extrusion for Van Slides

● Planning Your Van Slide Project

● Step-by-Step Guide to Building a Van Slide with 80/20 Aluminum Extrusion

>> Step 1: Gather Materials and Tools

>> Step 2: Cut the 80/20 Profiles

>> Step 3: Assemble the Frame

>> Step 4: Install Drawer Slides

>> Step 5: Create the Slide Top

>> Step 6: Attach the Slide Top

>> Step 7: Install the Slide in Your Van

>> Step 8: Test and Adjust

● Tips for a Successful 80/20 Van Slide Build

● Customizing Your Van Slide

● Maintenance and Care

● Conclusion

● Video Tutorial

● Frequently Asked Questions

>> Q1: How much weight can an 80/20 aluminum extrusion van slide support?

>> Q2: Can I use 80/20 aluminum extrusion for my entire van build, not just slides?

>> Q3: How does the cost of building with 80/20 compare to traditional wood construction?

>> Q4: Do I need special tools to work with 80/20 aluminum extrusion?

>> Q5: Is it possible to combine 80/20 aluminum extrusion with other materials in my van build?

Introduction

Van life has become increasingly popular in recent years, with more people embracing the freedom and flexibility of life on the road. One of the key aspects of creating a comfortable and functional living space in a van is efficient use of space. This is where the concept of van slides comes into play, and 80/20 aluminum extrusion has emerged as a game-changing material for van builders. In this comprehensive guide, we'll explore how to build a van slide using 80/20 aluminum extrusion, the benefits of this approach, and some tips and tricks to make your van build a success.

Understanding 80/20 Aluminum Extrusion

80/20 aluminum extrusion is a versatile building material that has gained popularity in various industries, including van conversions. It consists of modular aluminum profiles with T-slots that allow for easy assembly and customization. The name "80/20" comes from the Pareto principle, which suggests that 80% of effects come from 20% of causes. In the context of building materials, 80/20 aluminum extrusion aims to provide a solution that meets 80% of construction needs with 20% of the effort.

Benefits of Using 80/20 Aluminum Extrusion for Van Slides

There are several advantages to using 80/20 aluminum extrusion for building van slides:

1. Lightweight: Aluminum is significantly lighter than wood or steel, which is crucial for maintaining your van's fuel efficiency and staying within weight limits.

2. Strength: Despite its light weight, 80/20 aluminum extrusion is incredibly strong and can support heavy loads.

3. Modularity: The T-slot design allows for easy assembly, disassembly, and reconfiguration, making it perfect for evolving van builds.

4. Durability: Aluminum is resistant to rust and corrosion, ensuring longevity in various climates and conditions.

5. Precision: The extrusion process results in highly accurate and consistent profiles, allowing for precise fitment and smooth operation of sliding components.

6. Versatility: 80/20 can be used for various van build elements, including bed frames, cabinets, and kitchen units.

Planning Your Van Slide Project

Before diving into the construction process, it's essential to plan your van slide project carefully. Consider the following steps:

1. Measure your van's interior dimensions accurately.

2. Decide on the purpose and location of your slide (e.g., kitchen, storage, bed).

3. Sketch out your design, including dimensions and weight considerations.

4. Create a list of required 80/20 profiles, connectors, and accessories.

5. Plan for any additional components like drawer slides, hinges, or locking mechanisms.

Step-by-Step Guide to Building a Van Slide with 80/20 Aluminum Extrusion

Step 1: Gather Materials and Tools

To build your van slide, you'll need:

- 80/20 aluminum extrusion profiles (various sizes as per your design)

- Corner brackets and joining plates

- T-nuts and bolts

- Heavy-duty drawer slides

- Plywood or other surface material for the slide top

- Power drill

- Saw for cutting aluminum (preferably a miter saw with an aluminum cutting blade)

- Measuring tape

- Level

- Allen wrenches

- Safety equipment (goggles, gloves)

Step 2: Cut the 80/20 Profiles

Using your design measurements, cut the 80/20 profiles to the required lengths. Remember to account for the thickness of corner brackets and any other connecting hardware. Always wear safety goggles and gloves when cutting aluminum.

Step 3: Assemble the Frame

Begin by assembling the main frame of your slide. Use corner brackets to join the profiles at right angles. Ensure that everything is square and level as you go.

Step 4: Install Drawer Slides

Attach heavy-duty drawer slides to the sides of your frame. Make sure they are parallel and level to ensure smooth operation of your slide.

Step 5: Create the Slide Top

Cut a piece of plywood or another suitable material to fit the top of your slide frame. You may want to add a lip around the edges to prevent items from falling off when the slide is in use.

Step 6: Attach the Slide Top

Secure the slide top to the 80/20 frame using T-nuts and bolts. Make sure it's firmly attached and can support the intended weight.

Step 7: Install the Slide in Your Van

With the help of a friend, carefully install the completed slide in your van. Attach the fixed part of the drawer slides to sturdy points in your van's structure, ensuring everything is level and secure.

Step 8: Test and Adjust

Test your newly installed slide by gently pulling it out and pushing it back in. Make any necessary adjustments to ensure smooth operation and proper alignment.

Tips for a Successful 80/20 Van Slide Build

1. Use 3D design software to plan your build and visualize the end result.

2. Invest in quality drawer slides rated for the weight you plan to put on your slide.

3. Consider adding a locking mechanism to keep the slide secure while driving.

4. Use end caps on exposed 80/20 profile ends for a finished look and safety.

5. Incorporate cable management solutions if you plan to run electrical wires through your slide system.

Customizing Your Van Slide

One of the great advantages of using 80/20 aluminum extrusion is the ability to customize and adapt your design. Here are some ideas to enhance your van slide:

1. Add modular storage containers that fit perfectly within the 80/20 frame.

2. Incorporate LED lighting strips for better visibility.

3. Create a fold-out table or workstation that extends from the slide.

4. Install a slide-out cooktop or sink for a compact kitchen solution.

Maintenance and Care

To keep your 80/20 van slide functioning smoothly:

1. Periodically check and tighten all bolts and connections.

2. Clean the drawer slides and lubricate them as needed.

3. Inspect the slide for any signs of wear or damage, especially after rough road trips.

4. Keep the T-slots clean and free of debris to maintain the system's modularity.

Conclusion

Building a van slide with 80/20 aluminum extrusion offers a versatile, durable, and customizable solution for maximizing space in your van conversion. By following this guide and leveraging the unique properties of 80/20 profiles, you can create a functional and efficient sliding system that enhances your van life experience. Remember to prioritize safety, plan carefully, and don't be afraid to get creative with your design. Happy building!

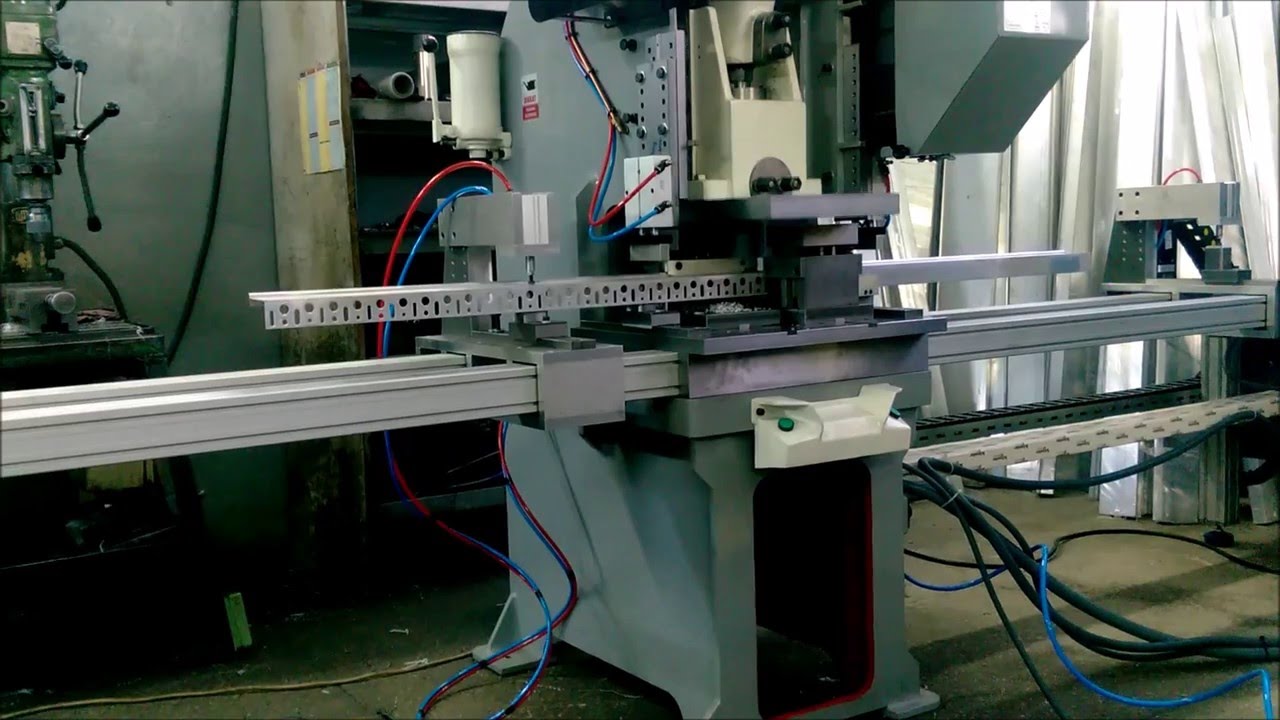

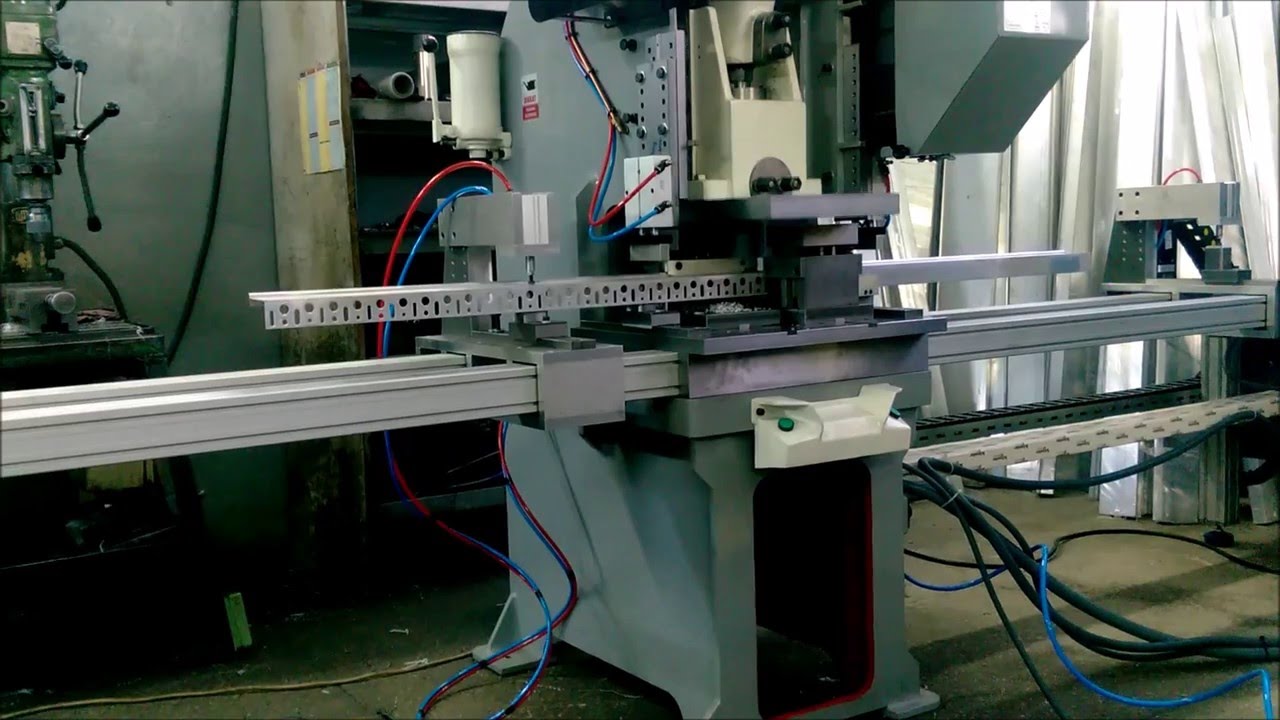

Video Tutorial

For a visual guide on building with 80/20 aluminum extrusion, check out this helpful video:

Frequently Asked Questions

Q1: How much weight can an 80/20 aluminum extrusion van slide support?

A1: The weight capacity of an 80/20 aluminum extrusion van slide depends on various factors, including the size and number of profiles used, the type of drawer slides, and the overall design. Generally, a well-constructed slide can support between 100 to 300 pounds. However, it's crucial to calculate the specific load requirements for your project and choose components rated for that weight.

Q2: Can I use 80/20 aluminum extrusion for my entire van build, not just slides?

A2: Absolutely! Many van builders use 80/20 aluminum extrusion for various aspects of their conversion, including bed frames, cabinet structures, roof racks, and even wall paneling support. Its versatility and strength make it an excellent choice for creating a fully customizable and modular van interior.

Q3: How does the cost of building with 80/20 compare to traditional wood construction?

A3: Initially, 80/20 aluminum extrusion can be more expensive than wood. However, when considering the long-term benefits such as durability, weight savings, and the ability to easily modify your build, many find it to be a worthwhile investment. Additionally, the time saved in construction and the potential for reusing materials in future builds can offset the higher upfront cost.

Q4: Do I need special tools to work with 80/20 aluminum extrusion?

A4: While specialized tools can make working with 80/20 easier, they're not absolutely necessary for most van build projects. Basic tools like a miter saw with an aluminum cutting blade, a drill, and Allen wrenches are usually sufficient. However, investing in a few 80/20-specific tools like a corner key insertion tool can speed up the assembly process.

Q5: Is it possible to combine 80/20 aluminum extrusion with other materials in my van build?

A5: Yes, one of the advantages of 80/20 is its compatibility with other materials. Many van builders combine 80/20 frames with wood panels, plastic sheets, or even fabric to create unique and functional designs. The T-slot profile allows for easy attachment of various materials, making it a versatile choice for hybrid construction methods.

Hot Tags: 80/20 Aluminum Extrusion Van Build, Diy Van Slide With Extruded Aluminum, Campervan Conversion Using 80/20 Framing, Lightweight Van Storage Solutions, Custom Van Interior With Aluminum Profiles, Aluminum Framing For Van Conversions, Modular Van Build Techniques, Van Life Organization With 80/20 System, Extruded Aluminum For Van Furniture, 80/20 Van Galley Drawers Installation, China, manufacturing company, manufacturers, suppliers, factory, price, Pricelist, quotation, wholesale