Content Menu

● Understanding Aluminum Extrusion

>> The Aluminum Extrusion Process

● Steps to Become an Aluminum Extrusion Press Operator

>> Complete High School or Equivalent

>> Pursue Technical Education

>> Gain Hands-On Experience

>> Obtain Certification

>> Apply for Positions

● Skills Required for an Aluminum Extrusion Press Operator

● Career Advancement Opportunities

● Innovations in Aluminum Extrusion Technology

>> 1. Artificial Intelligence Integration

>> 2. Advanced Cooling Techniques

>> 3. Sustainable Practices

>> 4. Hybrid Extrusion Techniques

>> 5. Nano-Coating Technologies

● The Future of Aluminum Extrusion Press Operators

● Conclusion

● FAQ

>> 1. Do I need a college degree to become an aluminum extrusion press operator?

>> 2. What industries employ aluminum extrusion press operators?

>> 3. How long does it take to become proficient as an aluminum extrusion press operator?

>> 4. Are there opportunities for advancement in this career?

>> 5. What is the job outlook for aluminum extrusion press operators?

● Citations:

Becoming an "aluminum extrusion press operator" is a rewarding career choice for those interested in manufacturing and machinery. This role involves operating and managing the equipment that shapes aluminum into various profiles used in construction, automotive, and other industries. This article will guide you through the steps to become an aluminum extrusion press operator, detailing the necessary education, skills, and career progression.

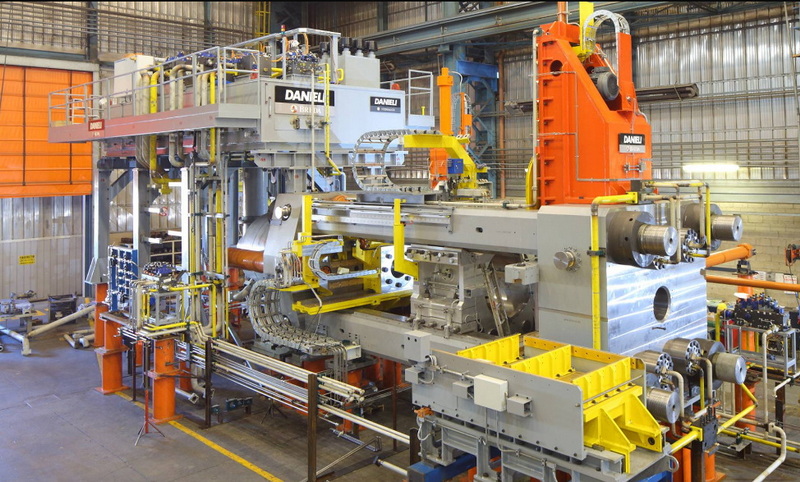

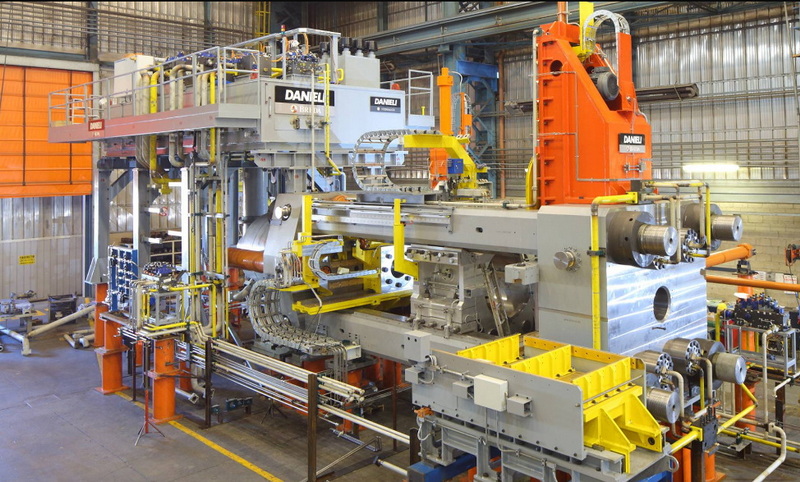

Understanding Aluminum Extrusion

Aluminum extrusion is a process that involves forcing aluminum through a die to create specific shapes. The process begins with heating aluminum billets until they are malleable, then using a hydraulic press to push the aluminum through a shaped die. The result is a continuous profile that can be cut to length for various applications.

The Aluminum Extrusion Process

1. Heating the Billet: The aluminum is heated to approximately 900°F (482°C) to make it pliable.

2. Extrusion: A hydraulic press pushes the heated aluminum through a die, forming it into the desired shape.

3. Cooling: The extruded profile is cooled, often in a water bath, to set its shape.

4. Cutting and Finishing: The extruded aluminum is cut to length and may undergo additional finishing processes such as anodizing or painting.

Steps to Become an Aluminum Extrusion Press Operator

Complete High School or Equivalent

A high school diploma or GED is the minimum educational requirement for becoming an aluminum extrusion press operator. Courses in mathematics, physics, and shop classes can provide foundational knowledge beneficial for this role.

Pursue Technical Education

While some operators learn on the job, enrolling in vocational or technical training programs can enhance your prospects. Consider programs in:

- Manufacturing technology

- Mechanical engineering

- Industrial technology

These programs often include coursework on machine operation, maintenance, and material science.

Gain Hands-On Experience

Experience is crucial in this field. Start by seeking entry-level positions in manufacturing environments. Apprenticeships or internships can provide structured learning opportunities that combine classroom instruction with practical experience.

Obtain Certification

Consider obtaining certification from recognized industry organizations such as the Aluminum Extruders Council (AEC). Certification can demonstrate your commitment to the profession and may make you more attractive to employers.

Apply for Positions

Look for job openings as an aluminum extrusion press operator in various industries including:

- Plastics manufacturing

- Metals processing

- Food production

Tailor your resume to highlight relevant skills and experiences.

Skills Required for an Aluminum Extrusion Press Operator

To be successful as an aluminum extrusion press operator, you should develop several key skills:

- Technical Proficiency: Understanding machinery operation and maintenance is essential.

- Attention to Detail: Precision is critical; operators must monitor machine settings closely.

- Problem-Solving Skills: The ability to troubleshoot issues quickly during production is vital.

- Physical Stamina: Operators often handle heavy materials and equipment.

- Safety Consciousness: Adhering to safety protocols helps prevent accidents in the workplace.

Career Advancement Opportunities

As you gain experience, there are numerous opportunities for advancement within the field of aluminum extrusion:

- Supervisory Roles: Experienced operators can move into supervisory positions overseeing teams of operators.

- Quality Control: Operators may transition into quality control roles, ensuring that products meet industry standards.

- Specialized Technical Positions: Further education may lead to specialized roles in areas such as CNC operation or robotics.

Innovations in Aluminum Extrusion Technology

The aluminum extrusion industry has seen significant advancements over recent years, driven by technological innovations aimed at improving efficiency and sustainability. Here are some key trends:

1. Artificial Intelligence Integration

The integration of artificial intelligence (AI) into extrusion processes allows for real-time monitoring and adjustments based on data analytics. AI systems can optimize parameters such as temperature and pressure during extrusion, ensuring consistent quality while reducing waste[3][4].

2. Advanced Cooling Techniques

New rapid quench systems have been developed to cool extrusions uniformly as they exit the press. These systems ensure more consistent tempering along the length of the extrusion, reducing straightness and twist deformations[3][4].

3. Sustainable Practices

The industry is increasingly focusing on sustainability by adopting practices such as closed-loop recycling of aluminum materials. This shift not only reduces waste but also lowers energy consumption during production[7][22].

4. Hybrid Extrusion Techniques

Hybrid techniques that combine traditional methods with advanced processes are emerging to produce aluminum profiles with enhanced strength and formability[4][8]. These methods optimize material properties for specific applications in aerospace and automotive sectors.

5. Nano-Coating Technologies

Recent developments in nano-coating technologies have improved the durability of aluminum extruded profiles by providing an extra layer of protection against corrosion and abrasion[4][8]. This advancement significantly extends the lifespan of products used across various industries.

The Future of Aluminum Extrusion Press Operators

As technology continues to evolve, so does the role of the aluminum extrusion press operator. Operators will need to adapt to new machinery equipped with advanced automation features and AI capabilities. Continuous learning will be essential as new techniques emerge, emphasizing precision control and sustainability.

Moreover, with the increasing demand for lightweight materials in industries such as automotive and construction, skilled operators will find ample job opportunities as companies seek experts who can manage sophisticated extrusion processes effectively[11][12].

Conclusion

Becoming an aluminum extrusion press operator requires a combination of education, hands-on experience, and skill development. With dedication and continuous learning, you can build a successful career in this dynamic field that plays a crucial role in modern manufacturing.

FAQ

1. Do I need a college degree to become an aluminum extrusion press operator?

No, a college degree is not required; however, technical training or certification can be beneficial.

2. What industries employ aluminum extrusion press operators?

Operators are employed in industries such as plastics manufacturing, metals processing, and food production.

3. How long does it take to become proficient as an aluminum extrusion press operator?

It typically takes between six months to two years of on-the-job training or apprenticeship to become proficient.

4. Are there opportunities for advancement in this career?

Yes, there are many opportunities for advancement into supervisory roles or specialized technical positions.

5. What is the job outlook for aluminum extrusion press operators?

The job outlook varies by region but generally remains stable due to ongoing demand in manufacturing sectors.

Citations:

[1] https://www.youtube.com/watch?v=ELgtjeJyFw8

[2] https://www.alexandriaindustries.com/press-releases/new-press-and-expansion/

[3] https://profileprecisionextrusions.com/the-evolution-of-aluminum-extrusions-emerging-trends-and-technologies/

[4] https://yamunaind.com/innovation-spotlight-recent-advancements-in-aluminium-extrusion-technology/

[5] https://www.youtube.com/watch?v=P8BWQBP4Vhk

[6] https://taberextrusions.com/a-brief-history-of-aluminum-extrusions/

[7] https://www.otalum.com/future-developments-and-trends-in-industrial-aluminum-extrusion-technology.html

[8] https://www.alcircle.com/news/tech-trends-driving-the-aluminium-extrusion-industry-111131

[9] https://kdmfab.com/aluminum-extrusion/

[10] https://www.alexandriaindustries.com/content-library/demand-innovation/aluminum-extrusion-increases-options-optimize-supply-chain/

[11] https://americandouglasmetals.com/2023/12/20/global-aluminum-extrusion-market-2023-2030-growth-trends-key-players-and-industry-insights/

[12] https://www.indeed.com/q-aluminum-extrusion-press-operator-jobs.html

[13] https://michiganextruded.com

[14] https://blog.tbrc.info/2024/10/aluminum-extrusion-market-overview/

[15] https://taberextrusions.com/how-taber-does-that-aluminum-extrusion-innovation-and-technology/

[16] https://www.indeed.com/career-advice/finding-a-job/what-does-extrusion-operator-do

[17] https://www.thefabricator.com/thefabricator/blog/assembly/an-aluminum-success-story

[18] https://www.thebrainyinsights.com/report/aluminum-extrusion-market-13118

[19] https://nationalindustries.world/2025/01/02/the-future-of-aluminum-how-extrusion-technology-is-transforming-industries/

[20] https://www.yjing-extrusion.com/what-does-an-aluminum-extrusion-press-operator-do.html

[21] https://www.linkedin.com/advice/3/what-does-extrusion-operator-do-skills-service-operations-m3szc

[22] https://www.imarcgroup.com/aluminium-extrusion-market-statistics

[23] https://www.psiextrusions.com/blog/innovations-in-aluminum-extrusion-sustainability-and-ai/

[24] https://www.reddit.com/r/engineering/comments/29c5yf/just_started_a_new_job_as_an_aluminum_extrusion/

[25] https://www.indeed.com/cmp/American-Aluminum-Extrusion-Company,-LLC/reviews?ftopic=mgmt

[26] https://www.harboraluminum.com/en/news/automotive-aluminum-extrusions-challenges-and-opportunities

[27] https://www.linkedin.com/pulse/aluminum-extrusion-key-insights-engineers-project-managers-ukgac

[28] https://www.alcirclebiz.com/blogs/innovations-in-aluminium-extrusion-meeting-modern-industry-demands