Content Menu

● Understanding 2020 Aluminum Extrusion V-Slot

>> What is 2020 Aluminum Extrusion?

>> Benefits of Using V-Slot Profiles

● Materials and Tools Needed

>> Materials

>> Tools

● Step-by-Step Assembly Instructions

>> Step 1: Planning Your Design

>> Step 2: Cutting the Aluminum Profiles

>> Step 3: Preparing the V-Slot Profiles

>> Step 4: Inserting T-Nuts

>> Step 5: Assembling the Frame

>> Step 6: Finishing Touches

● Tips for Successful Assembly

● Advanced Techniques for Customization

>> Custom Brackets and Connectors

>> Integrating Electronics

>> Adding Mobility

● Conclusion

● Common Questions and Answers

>> 1. What tools do I need to assemble a 2020 aluminum extrusion frame?

>> 2. Can I cut the aluminum profiles myself?

>> 3. What is the best way to ensure my frame is square?

>> 4. How do I attach components to the V-slot profiles?

>> 5. Can I use 2020 aluminum extrusion for outdoor projects?

Assembling a custom frame using 2020 aluminum extrusion V-slot profiles is a popular choice among DIY enthusiasts, engineers, and makers. This versatile material allows for the creation of robust and lightweight structures suitable for various applications, including 3D printers, CNC machines, and custom furniture. In this guide, we will walk you through the process of assembling a custom frame, covering everything from the necessary materials and tools to step-by-step assembly instructions.

Understanding 2020 Aluminum Extrusion V-Slot

What is 2020 Aluminum Extrusion?

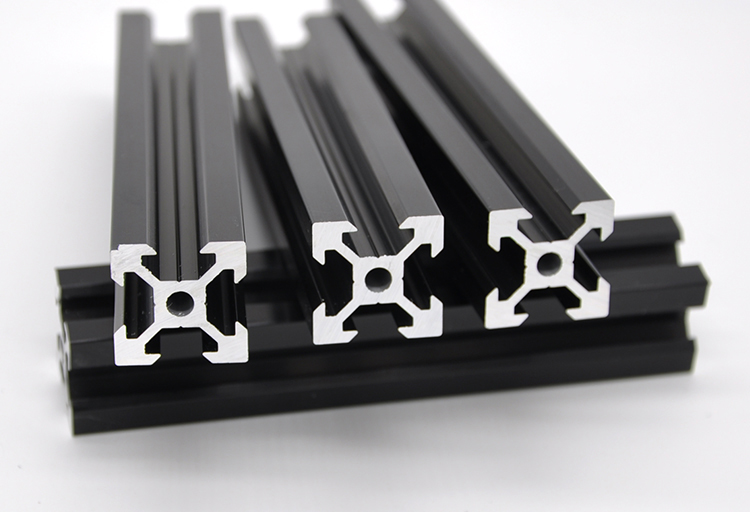

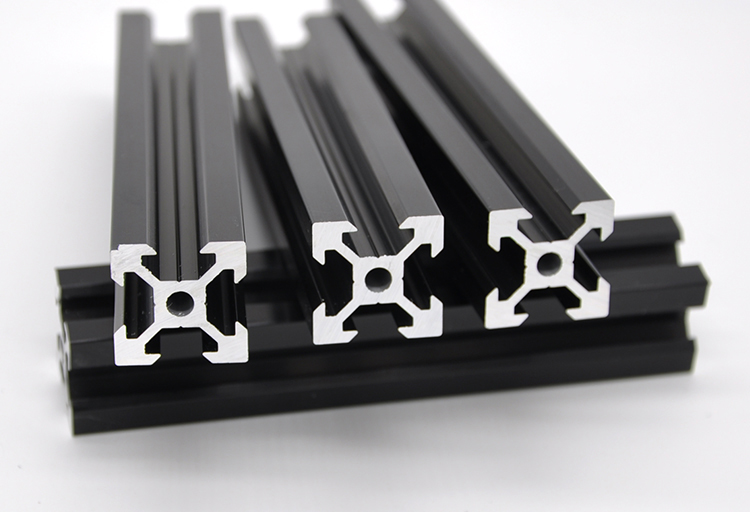

2020 aluminum extrusion refers to a specific profile size, measuring 20mm x 20mm. The "V-slot" design features a groove along each side, allowing for the easy attachment of various components, such as brackets, wheels, and other hardware. This design not only provides structural integrity but also facilitates smooth linear motion, making it ideal for applications that require movement.

Benefits of Using V-Slot Profiles

1. Modularity: V-slot profiles can be easily cut to length and assembled in various configurations, allowing for endless design possibilities.

2. Strength: Aluminum is a lightweight yet strong material, making it suitable for both small and large structures.

3. Ease of Assembly: The T-slot design allows for quick and easy assembly using standard fasteners, reducing the need for specialized tools.

4. Versatility: V-slot profiles can be used in a wide range of applications, from robotics to furniture design.

Materials and Tools Needed

Before you begin assembling your custom frame, gather the following materials and tools:

Materials

- 2020 Aluminum Extrusion V-Slot Profiles: Determine the lengths needed for your frame.

- Corner Brackets: For connecting the profiles at right angles.

- T-Nuts: These fit into the V-slots and allow for secure fastening.

- Bolts and Screws: To secure the profiles and brackets together.

- End Caps: To finish the ends of the profiles and provide a clean look.

Tools

- Miter Saw or Hacksaw: For cutting the aluminum profiles to the desired lengths.

- Drill: For making any additional holes if necessary.

- Allen Wrench: For tightening the bolts.

- Measuring Tape: To ensure accurate measurements.

- Square: To check for right angles during assembly.

Step-by-Step Assembly Instructions

Step 1: Planning Your Design

Before cutting any materials, sketch out your design. Consider the dimensions and layout of your frame. This will help you determine how many profiles you need and the lengths required. Planning is crucial to avoid wasting materials and to ensure that your frame meets your specific needs.

Step 2: Cutting the Aluminum Profiles

Using a miter saw or hacksaw, cut the aluminum profiles to the lengths specified in your design. Ensure that your cuts are straight and clean to facilitate proper assembly. If you are unsure about cutting the profiles yourself, many suppliers offer cutting services for a small fee.

Step 3: Preparing the V-Slot Profiles

Once cut, clean the edges of the profiles to remove any burrs or sharp edges. This will help prevent injuries during assembly and ensure a snug fit when connecting the profiles. A file or sandpaper can be used for this purpose.

Step 4: Inserting T-Nuts

Insert T-nuts into the V-slots of the profiles where you will be attaching brackets or other components. Make sure they are positioned correctly to align with the holes in your brackets. It's often helpful to have a few extra T-nuts on hand in case of any misalignment during assembly.

Step 5: Assembling the Frame

1. Start with the Base: Lay out the base of your frame on a flat surface. Use corner brackets to connect the profiles at each corner. Secure them with bolts and T-nuts.

2. Add Vertical Supports: Attach vertical profiles to the corners of the base. Use brackets to secure them in place. Ensure everything is square by measuring diagonally across the frame.

3. Attach the Top Frame: Once the vertical supports are secure, add the top profiles to complete the frame structure. Again, use corner brackets and T-nuts to secure everything.

4. Check for Stability: Once the frame is assembled, check for stability. Make any necessary adjustments to ensure everything is tight and secure. It's important to periodically check the tightness of the bolts during the assembly process to avoid any wobbling in the final structure.

Step 6: Finishing Touches

After the frame is assembled, you can add any additional components, such as shelves, panels, or other features. Use end caps to cover the exposed ends of the profiles for a clean finish. This not only improves the aesthetics of your frame but also prevents dust and debris from accumulating inside the profiles.

Tips for Successful Assembly

- Double-Check Measurements: Always measure twice before cutting to avoid mistakes. This is especially important when working with expensive materials like aluminum.

- Use a Level: Ensure that your frame is level during assembly to prevent any structural issues later on. A small level tool can be very helpful in this regard.

- Tighten Bolts Securely: Make sure all bolts are tightened properly to maintain the integrity of the frame. A loose bolt can lead to structural failure over time.

- Consider Weight Distribution: If your frame will support weight, consider how the load will be distributed across the structure. This is particularly important for frames that will hold heavy equipment or materials.

Advanced Techniques for Customization

Once you have mastered the basics of assembling a frame using 2020 aluminum extrusion V-slot profiles, you can explore advanced techniques to enhance your projects further.

Custom Brackets and Connectors

For unique designs, consider creating custom brackets and connectors. Using a 3D printer, you can design and print parts that fit your specific needs, allowing for greater flexibility in your designs. This can be particularly useful for complex assemblies where standard brackets may not provide the necessary support.

Integrating Electronics

If your frame will house electronics, such as in a 3D printer or CNC machine, plan for cable management. Use cable clips or channels to keep wires organized and out of the way. This not only improves the appearance of your project but also prevents damage to the cables.

Adding Mobility

For projects that require mobility, consider adding wheels or casters to the base of your frame. Ensure that the wheels are rated for the weight of your frame and any additional loads it will carry. This will make it easier to move your project around as needed.

Conclusion

Assembling a custom frame using 2020 aluminum extrusion V-slot profiles is a straightforward process that offers endless possibilities for creativity and functionality. With the right materials, tools, and a clear plan, you can create a sturdy and versatile frame for your projects. Whether you're building a 3D printer, a CNC machine, or custom furniture, the modular nature of V-slot profiles makes it an excellent choice for any DIY enthusiast. By following the steps outlined in this guide and considering the advanced techniques discussed, you can take your projects to the next level and create something truly unique.

Common Questions and Answers

1. What tools do I need to assemble a 2020 aluminum extrusion frame?

You will need a miter saw or hacksaw, drill, Allen wrench, measuring tape, and square.

2. Can I cut the aluminum profiles myself?

Yes, you can cut the profiles using a miter saw or hacksaw. Just ensure your cuts are straight.

3. What is the best way to ensure my frame is square?

Measure diagonally across the frame. If the measurements are equal, your frame is square.

4. How do I attach components to the V-slot profiles?

Use T-nuts that fit into the V-slots and secure components with bolts.

5. Can I use 2020 aluminum extrusion for outdoor projects?

Yes, aluminum is resistant to corrosion, making it suitable for outdoor use. However, consider using anodized profiles for added protection.