Content Menu

● Introduction

● Understanding the Aluminum Extrusion Process

● Essential Skills and Qualifications

● Daily Responsibilities

● Safety Protocols and Best Practices

● Quality Control and Production Standards

● Career Development and Growth

● Industry Trends and Technology

● Environmental Considerations

● Conclusion

● Frequently Asked Questions

>> Q1: What qualifications are needed to become an Aluminum Extrusion Press Operator?

>> Q2: What are the typical working hours for an Aluminum Extrusion Press Operator?

>> Q3: What are the main challenges faced by Aluminum Extrusion Press Operators?

>> Q4: How does an Aluminum Extrusion Press Operator ensure product quality?

>> Q5: What career advancement opportunities are available?

Introduction

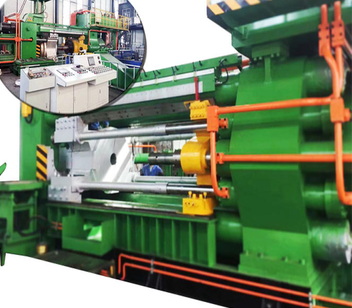

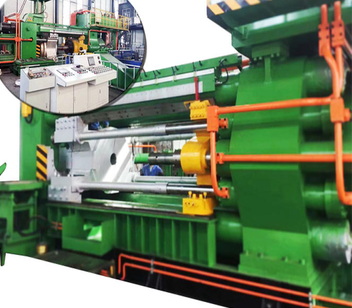

The role of an Aluminum Extrusion Press Operator is crucial in the metal manufacturing industry. These skilled professionals are responsible for operating sophisticated machinery that transforms aluminum billets into various shapes and profiles through the extrusion process.

Understanding the Aluminum Extrusion Process

The aluminum extrusion process involves heating aluminum billets to specific temperatures and forcing them through specially designed dies to create desired profiles. As an Aluminum Extrusion Press Operator, understanding this process is fundamental to success in the role.

Essential Skills and Qualifications

A successful Aluminum Extrusion Press Operator must possess:

- Technical expertise in operating extrusion equipment

- Understanding of aluminum properties and behavior

- Knowledge of safety protocols and procedures

- Ability to read and interpret technical drawings

- Strong attention to detail

- Physical stamina and dexterity

- Problem-solving capabilities

- Communication skills

Daily Responsibilities

The typical duties of an Aluminum Extrusion Press Operator include:

- Setting up and operating extrusion press machinery

- Monitoring production parameters

- Quality control inspection

- Maintaining equipment

- Recording production data

- Troubleshooting technical issues

- Ensuring safety compliance

- Coordinating with team members

Safety Protocols and Best Practices

Safety is paramount in aluminum extrusion operations. Operators must:

- Wear appropriate personal protective equipment

- Follow lockout/tagout procedures

- Maintain clean work areas

- Monitor equipment conditions

- Report safety concerns

- Participate in safety training

- Follow emergency procedures

- Maintain proper documentation

Quality Control and Production Standards

Maintaining product quality is essential. Operators must:

- Check dimensional accuracy

- Monitor surface finish

- Verify material properties

- Document quality checks

- Implement corrective actions

- Maintain production records

- Collaborate with quality teams

- Follow industry standards

Career Development and Growth

Advancement opportunities for Aluminum Extrusion Press Operators include:

- Senior operator positions

- Production supervisor roles

- Quality control specialist

- Technical trainer

- Maintenance technician

- Process improvement specialist

- Operations manager

- Manufacturing consultant

Industry Trends and Technology

The aluminum extrusion industry continues to evolve with:

- Automated control systems

- Advanced monitoring equipment

- Improved die designs

- Energy-efficient processes

- Enhanced safety features

- Digital documentation

- Predictive maintenance

- Sustainable practices

Environmental Considerations

Modern aluminum extrusion operations focus on:

- Energy efficiency

- Waste reduction

- Material recycling

- Environmental compliance

- Sustainable practices

- Resource conservation

- Emissions control

- Green manufacturing

Conclusion

The role of an Aluminum Extrusion Press Operator is dynamic and essential in modern manufacturing. Success in this career requires a combination of technical skills, safety awareness, and commitment to quality. As the industry continues to evolve, operators must stay current with new technologies and practices while maintaining high standards of production excellence.

Frequently Asked Questions

Q1: What qualifications are needed to become an Aluminum Extrusion Press Operator?

A1: Typically, a high school diploma or equivalent is required, along with technical training or apprenticeship. Some employers may require post-secondary education in manufacturing or related fields. On-the-job training is usually provided.

Q2: What are the typical working hours for an Aluminum Extrusion Press Operator?

A2: Most operators work in shifts, which may include days, nights, weekends, and holidays. Shifts typically run 8-12 hours, and overtime may be required during peak production periods.

Q3: What are the main challenges faced by Aluminum Extrusion Press Operators?

A3: Common challenges include maintaining consistent product quality, troubleshooting equipment issues, adapting to new technologies, managing physical demands, and ensuring safety compliance while meeting production targets.

Q4: How does an Aluminum Extrusion Press Operator ensure product quality?

A4: Operators maintain quality through regular inspections, monitoring process parameters, checking dimensional accuracy, verifying surface finish, and following quality control procedures. They also document results and implement corrective actions when needed.

Q5: What career advancement opportunities are available?

A5: Experienced operators can advance to senior positions, become supervisors, specialize in quality control, move into maintenance roles, or pursue management positions. Additional training and certification can enhance career prospects.