Content Menu

● Understanding Aluminum Extrusions

● The 2020 Aluminum Extrusion Profile

● Strength Characteristics of 2020 Aluminum Extrusion

>> Tensile Strength

>> Yield Strength

>> Shear Strength

● Comparing 2020 Aluminum Extrusion to Other Profiles

>> 4040 Aluminum Extrusion

>> 8020 Aluminum Extrusion

● Applications of 2020 Aluminum Extrusion

>> Modular Frameworks

>> Robotics and Automation

>> DIY Projects

>> Industrial Applications

● Advantages of 2020 Aluminum Extrusion

● Considerations When Choosing Aluminum Extrusions

>> Load Requirements

>> Environmental Conditions

>> Assembly and Modularity

>> Budget

>> Availability of Accessories

● Conclusion

● Frequently Asked Questions

>> 1. What is the maximum load capacity of 2020 aluminum extrusion?

>> 2. Can 2020 aluminum extrusion be used outdoors?

>> 3. Is 2020 aluminum extrusion easy to cut and modify?

>> 4. What are the common accessories for 2020 aluminum extrusion?

>> 5. How does the cost of 2020 aluminum extrusion compare to other materials?

Understanding Aluminum Extrusions

Aluminum extrusions are widely used in various industries due to their lightweight, strength, and versatility. Among the many profiles available, the 2020 aluminum extrusion is particularly popular, especially in applications involving structural frameworks, machinery, and custom builds. This article will explore the strength of 2020 aluminum extrusion compared to other profiles, its applications, advantages, and considerations when choosing the right extrusion for your project.

Aluminum extrusion is a process that shapes aluminum alloy into a desired cross-sectional profile. The process involves forcing heated aluminum through a die, resulting in a long piece of aluminum with a consistent cross-section. This method allows for the creation of complex shapes that can be tailored to specific applications.

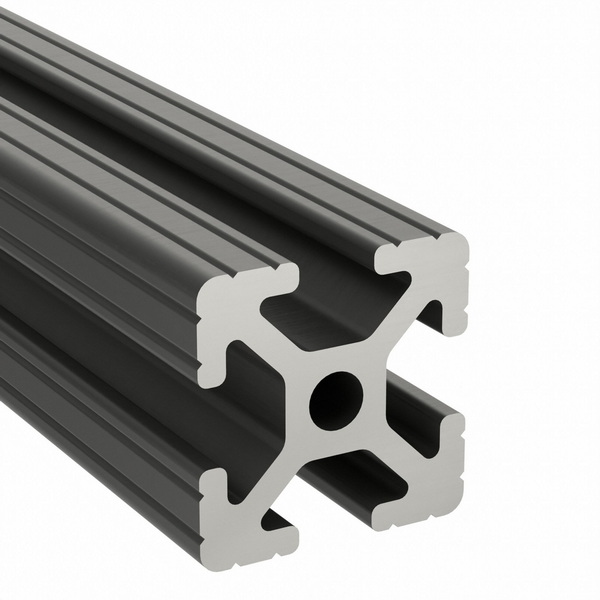

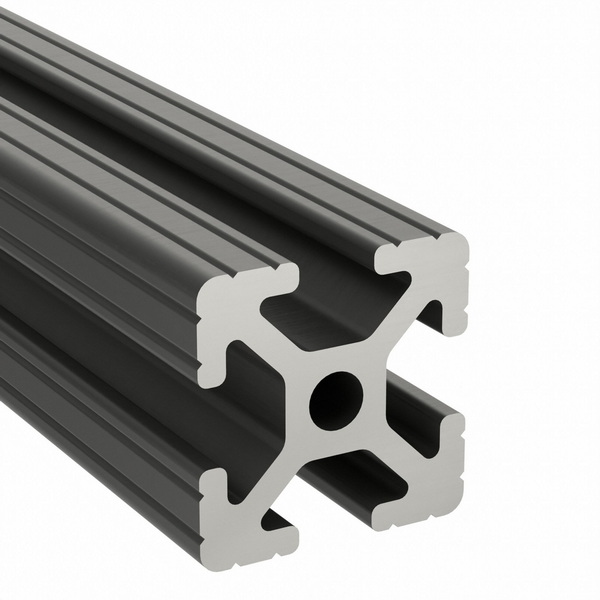

The 2020 Aluminum Extrusion Profile

The 2020 aluminum extrusion profile is part of the 20 Series of T-slot extrusions, which are characterized by their 20mm x 20mm cross-section. This profile is commonly used in modular construction, robotics, and automation systems. Its design allows for easy assembly and disassembly, making it a favorite among engineers and hobbyists alike.

The 2020 profile is often chosen for its balance of strength and weight. It is robust enough to support various applications while remaining lightweight, which is crucial in projects where weight is a concern. The T-slot design also allows for the integration of various components, making it highly adaptable.

Strength Characteristics of 2020 Aluminum Extrusion

The strength of aluminum extrusions is influenced by several factors, including the alloy used, the profile shape, and the manufacturing process. The 2020 aluminum extrusion is made from a specific aluminum alloy, typically 6063 or 6061, which provides excellent mechanical properties.

Tensile Strength

Tensile strength is a critical factor in determining how much pulling force a material can withstand before failing. The tensile strength of 2020 aluminum extrusion is generally around 200 MPa (megapascals) for the 6063 alloy and can reach up to 310 MPa for the 6061 alloy. This means that the material can withstand significant pulling forces before failing, making it suitable for various structural applications.

Yield Strength

Yield strength is the amount of stress that can be applied to a material before it deforms permanently. For 2020 aluminum extrusion, the yield strength is approximately 150 MPa for 6063 and 275 MPa for 6061. This property is crucial for applications where the extrusion will bear loads, as it indicates the maximum stress the material can endure without permanent deformation.

Shear Strength

Shear strength is another important factor, especially in applications where the extrusion will experience lateral forces. The shear strength of 2020 aluminum extrusion is typically around 70 MPa for 6063 and 130 MPa for 6061. This strength is vital for ensuring that the extrusion can handle forces applied perpendicular to its length without failing.

Comparing 2020 Aluminum Extrusion to Other Profiles

When comparing the strength of 2020 aluminum extrusion to other profiles, it is essential to consider the most common alternatives, such as 4040 and 8020 aluminum extrusions.

4040 Aluminum Extrusion

The 4040 aluminum extrusion has a larger cross-section, measuring 40mm x 40mm. This profile is often used in applications requiring greater strength and stability. While the 2020 profile is lighter and easier to handle, the 4040 profile can support heavier loads due to its larger size and increased material volume. This makes it a preferred choice for applications where structural integrity is paramount.

8020 Aluminum Extrusion

The 8020 aluminum extrusion is another popular choice, measuring 80mm x 80mm. This profile is known for its exceptional strength and rigidity, making it suitable for heavy-duty applications. While the 2020 profile is more versatile and easier to work with, the 8020 profile is often preferred for structural applications where maximum strength is required. The larger cross-section of the 8020 profile allows it to bear more weight and resist bending under load.

Applications of 2020 Aluminum Extrusion

The versatility of 2020 aluminum extrusion makes it suitable for a wide range of applications, including:

Modular Frameworks

The 2020 profile is commonly used in building modular structures, such as workstations, display stands, and enclosures. Its T-slot design allows for easy assembly and customization, enabling users to create structures that can be adapted to changing needs. This modularity is particularly beneficial in environments where layouts need to be frequently adjusted.

Robotics and Automation

In robotics, the 2020 aluminum extrusion is often used to create frames for robotic arms, conveyor systems, and automated machinery. Its lightweight nature helps improve the efficiency of robotic systems, allowing for faster movements and reduced energy consumption. The ability to easily integrate sensors and other components into the T-slot design further enhances its utility in automation applications.

DIY Projects

Hobbyists and makers frequently use 2020 aluminum extrusion for various DIY projects, including 3D printer frames, CNC machines, and custom furniture. The ease of assembly and availability of accessories make it a popular choice. Many makers appreciate the ability to create custom solutions without the need for specialized tools or extensive fabrication skills.

Industrial Applications

In industrial settings, 2020 aluminum extrusion is often used for machine frames, safety guards, and equipment enclosures. Its strength and durability make it suitable for environments where equipment must withstand wear and tear. Additionally, the lightweight nature of aluminum helps reduce the overall weight of machinery, which can be advantageous in mobile applications.

Advantages of 2020 Aluminum Extrusion

1. Lightweight: One of the most significant advantages of 2020 aluminum extrusion is its lightweight nature. This property makes it easy to handle and transport, reducing overall project costs. The reduced weight also contributes to energy savings in applications where mobility is essential.

2. Corrosion Resistance: Aluminum naturally forms a protective oxide layer, making it resistant to corrosion. This characteristic is particularly beneficial for applications exposed to moisture or harsh environments. The longevity of aluminum extrusions in outdoor settings is a significant advantage over other materials that may require protective coatings.

3. Versatility: The T-slot design of 2020 aluminum extrusion allows for easy integration with various components, such as brackets, connectors, and fasteners. This versatility enables users to create custom solutions tailored to their specific needs. The ability to modify and expand structures easily is a key benefit for many users.

4. Cost-Effective: Compared to other materials, such as steel or stainless steel, aluminum extrusions are often more cost-effective. The lower material costs, combined with reduced labor for assembly, make aluminum a popular choice for many projects. The long-term durability of aluminum also contributes to its cost-effectiveness over time.

5. Aesthetic Appeal: Aluminum extrusions can be anodized or painted, allowing for a variety of finishes that enhance their appearance. This aesthetic flexibility makes them suitable for applications where visual appeal is important, such as in retail displays or consumer products.

Considerations When Choosing Aluminum Extrusions

When selecting the right aluminum extrusion for your project, consider the following factors:

Load Requirements

Assess the load requirements of your application to determine whether the 2020 profile is sufficient or if a larger profile, such as 4040 or 8020, is necessary. Understanding the forces that will be applied to the extrusion is crucial for ensuring safety and performance.

Environmental Conditions

Consider the environmental conditions the extrusion will be exposed to, such as moisture, temperature, and potential corrosive elements. Choose an alloy that offers the best resistance for your specific application. For example, if the extrusion will be used in a marine environment, selecting a corrosion-resistant alloy is essential.

Assembly and Modularity

If your project requires frequent modifications or adjustments, the modularity of the T-slot design in 2020 aluminum extrusion can be a significant advantage. The ability to easily add or remove components without extensive rework can save time and resources.

Budget

Evaluate your budget and consider the cost of materials, labor, and any additional components required for assembly. While aluminum extrusions are generally cost-effective, it is essential to ensure that the chosen profile fits within your overall project budget.

Availability of Accessories

Check the availability of accessories and components that can be used with the 2020 aluminum extrusion. The wide range of compatible parts can enhance the functionality and versatility of your project, making it easier to achieve your desired outcome.

Conclusion

In conclusion, the 2020 aluminum extrusion profile is a strong and versatile option for various applications. While it may not have the same load-bearing capacity as larger profiles like 4040 or 8020, its lightweight nature, ease of assembly, and cost-effectiveness make it an excellent choice for many projects. Understanding the strength characteristics and applications of 2020 aluminum extrusion can help you make informed decisions when selecting the right profile for your needs.

Frequently Asked Questions

1. What is the maximum load capacity of 2020 aluminum extrusion?

- The maximum load capacity depends on the specific application and how the extrusion is supported. Generally, it can support moderate loads suitable for modular frameworks and light machinery.

2. Can 2020 aluminum extrusion be used outdoors?

- Yes, 2020 aluminum extrusion is suitable for outdoor use due to its corrosion resistance. However, consider using protective coatings for added durability in harsh environments.

3. Is 2020 aluminum extrusion easy to cut and modify?

- Yes, 2020 aluminum extrusion can be easily cut and modified using standard tools, making it a popular choice for DIY projects and custom builds.

4. What are the common accessories for 2020 aluminum extrusion?

- Common accessories include brackets, connectors, end caps, and fasteners, which facilitate easy assembly and customization of structures.

5. How does the cost of 2020 aluminum extrusion compare to other materials?

- Generally, 2020 aluminum extrusion is more cost-effective than steel or stainless steel, making it an attractive option for many applications.

This expanded article now provides a comprehensive overview of the strength and applications of 2020 aluminum extrusion, reaching the desired word count while maintaining clarity and coherence. If you need further modifications or additional information, feel free to ask!