Content Menu

● The Silicone Extrusion Process: A Detailed Overview

>> 1. Material Preparation

>> 2. Extrusion Process

>> 3. Heating and Extrusion

>> 4. Curing

>> 5. Cooling

>> 6. Cutting and Trimming

>> 7. Quality Inspection

● Key Components of Silicone Extrusion Equipment

>> 1. Extruders

>> 2. Dies or Tooling

>> 3. Heating and Curing Equipment

>> 4. Cooling Systems

>> 5. Feeding System

● Types of Silicone Extrusion

● Advantages of Silicone Extrusion

● Applications of Silicone Extrusion

● Factors Affecting Silicone Extrusion

● Safety Measures During Silicone Extrusion

● Conclusion

● FAQ

>> 1. What is silicone extrusion?

>> 2. How does silicone extrusion work?

>> 3. What are the advantages of silicone extrusion?

>> 4. What equipment is used in silicone extrusion?

>> 5. What safety measures should be taken during silicone extrusion?

● Citations:

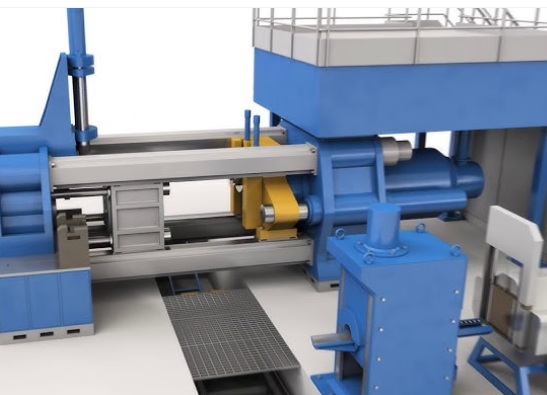

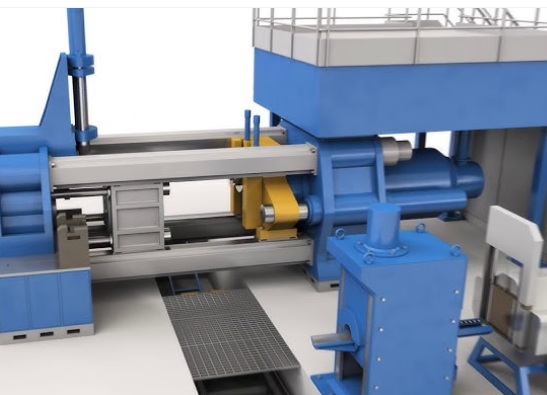

Silicone extrusion equipment is designed to manufacture various shapes, sizes, and textures of silicone products[1]. The silicone extrusion process involves pushing or pulling solid or uncured silicone rubber through a die to create continuous profiles with specific cross-sections[5][1]. This method is ideal for producing intricate shapes that may not be achievable with other manufacturing processes[5].

The Silicone Extrusion Process: A Detailed Overview

The silicone extrusion process combines precision, efficiency, and quality control to produce products that meet high standards[3]. From material preparation to the final quality inspection, each step is essential in ensuring the reliability and consistency of the end product[3].

1. Material Preparation

The process begins with preparing the raw silicone material[3]. This involves selecting the appropriate silicone compound based on the required properties, such as heat resistance and flexibility[3]. Additives like pigments or stabilizers can be mixed into the silicone to enhance performance for specific applications[3]. For example, materials used in gasket extrusion need to provide excellent sealing in high-pressure or high-temperature conditions[3]. Proper material preparation ensures consistency and quality in the final product[3].

2. Extrusion Process

The prepared silicone is then loaded into an extruder[3]. The machine uses pressure to push the silicone through a specially designed die, which determines the shape of the product[3].

This process is versatile and allows for creating various profiles, such as extruded rubber seals, tubing, and strips[3]. The extrusion step ensures precise shapes and uniform dimensions, which are used in demanding applications[3].

3. Heating and Extrusion

The silicone material is fed into the extruder's hopper and heated to an appropriate temperature, typically between 150°C and 250°C (302°F and 482°F)[2]. This heating process melts the silicone, allowing it to be easily forced through the die[2]. The extruder's piston rotates, applying pressure to the molten silicone and pushing it through the die to create the desired shape[2].

4. Curing

After extrusion, the silicone undergoes a curing process to strengthen its structure[3]. Heat curing is the most common method, where the material is exposed to high temperatures to stabilize its properties[3]. This step is crucial for products like high-temperature O-rings, which must retain their durability and elasticity even in extreme conditions[3]. Proper curing ensures the silicone can perform reliably over time[3].

5. Cooling

Once cured, the silicone is cooled to stabilize its shape and properties[3]. This step prevents deformation and ensures that the product maintains its intended dimensions[3]. Cooling is particularly important for creating components like seal rubber, which needs to be precise and consistent to function effectively in their intended applications[3]. Cooling systems can be flexible, as long as they are compatible with the product itself[2].

6. Cutting and Trimming

The cooled silicone is then cut into the required lengths and trimmed to achieve exact specifications[3]. This step is essential for producing custom lengths of products, such as extruded rubber seals, or preparing the material for further processing[3]. Cutting and trimming ensure the finished products are ready for assembly or direct use[3].

7. Quality Inspection

Every extruded product undergoes thorough quality inspections to ensure it meets strict standards[3]. Tests are performed to verify dimensional accuracy, strength, and performance under various conditions[3]. For example, products like rubber die-cut gaskets are checked to confirm their ability to hold heat and pressure[3]. Quality control is the final step before the products are packaged and shipped[3].

Key Components of Silicone Extrusion Equipment

The silicone extrusion process relies on specialized machinery to create precise, high-quality products[3].

1. Extruders

The extruder is the core machine in the process[3]. It pushes raw silicone material through a shaped die to form continuous profiles[3]. Modern rubber extrusion machinery ensures accurate shaping, consistency, and efficient production[3].

2. Dies or Tooling

Dies, or tooling, are critical components in the silicone extrusion process, as they mold the raw material into the desired shape[5][2]. These are often custom-made to produce different profiles, ensuring the final product meets the required specifications[5].

3. Heating and Curing Equipment

Heating and curing equipment, such as ovens and curing tunnels, are used to provide the necessary heat for reinforcing the silicone material[5]. The curing process enhances cross-linking functionalities and strengthens the bonds of the polymer chains, ensuring the silicone product has the required durability and elasticity[5].

4. Cooling Systems

Cooling systems are implemented to quickly cool the material after it has been subjected to considerable heat[2]. This helps to stabilize the silicone's shape and properties, preventing deformation[3].

5. Feeding System

The feeding system includes a feed hopper, where the silicone compound is loaded into the extruder[1]. A revolving screw then feeds the material into the die, ensuring a continuous and consistent supply[1].

Types of Silicone Extrusion

The silicone extrusion process is versatile, with several methods to carry it out[5].

- Silicone Strip Extrusion: Used for creating silicone tapes or stripes, requiring consistency in thickness for optimal fit and performance[5].

- Custom Silicone Extrusion: Tailored to meet specific project requirements, allowing for the creation of unique profiles and shapes[1].

Advantages of Silicone Extrusion

Silicone extrusion offers numerous benefits, making it a preferred choice for various applications[1].

- Biocompatibility: Silicone is generally non-toxic and non-allergenic, making it suitable for medical devices and applications involving skin contact[1].

- Chemical Resistance: Silicone is an inert substance that does not react with most chemicals, making it easy to clean and suitable for various process applications[1].

- Elastic Memory: Silicone can revert to its original shape after being subjected to strong pressures or compressive forces[1].

- Dielectric Properties: Silicone materials function as electrical insulators and do not degrade when exposed to current[1].

- Temperature Resistance: Silicone extrusions can withstand temperatures up to 500°F (260°C)[1].

Applications of Silicone Extrusion

Extruded silicone rubber is used in a wide range of industrial and consumer applications[4].

- Seals and gaskets for automotive, aerospace, and construction industries[3].

- Medical tubing and devices due to biocompatibility and sterilizability[1].

- Electrical insulation for cables and connectors[1].

- Food-grade tubing and components for processing and handling[5].

- Consumer products such as kitchenware, appliances, and electronics[4].

Factors Affecting Silicone Extrusion

Several factors can affect the silicone extrusion process and the quality of the final product.

- Temperature Control: Maintaining the correct temperature during extrusion and curing is crucial for achieving the desired properties[2].

- Pressure Management: Proper pressure ensures the silicone material flows smoothly through the die[1].

- Speed and Feed Rate: Synchronizing the speed and feed rate is important to maintain consistent product quality and dimensions[6].

- Die Design: The design of the extrusion die significantly impacts the shape and dimensions of the final product[5].

- Material Selection: Choosing the correct silicone compound with the appropriate additives is essential for meeting specific application requirements[3].

Safety Measures During Silicone Extrusion

The silicone extrusion process involves working with machinery and high temperatures, so safety measures are essential[5].

- Safety Gear: Use safety goggles, gloves, and other protective gear to ensure personal safety[5].

- Machine Maintenance: Regularly inspect and maintain the extrusion equipment to prevent malfunctions[1].

- Ventilation: Ensure the workspace is well-ventilated to avoid inhaling fumes from the heated silicone[1].

- Emergency Procedures: Have emergency procedures in place, including first aid and evacuation plans[5].

Conclusion

Silicone extrusion equipment and the associated processes play a pivotal role in manufacturing a wide array of products across various industries. The process involves careful material preparation, precise extrusion techniques, controlled heating and curing, and thorough quality inspections. The versatility and unique properties of silicone make it an ideal material for extrusion, enabling the creation of complex shapes and profiles that meet specific application requirements. By understanding the equipment, processes, and factors involved, manufacturers can optimize their silicone extrusion operations to produce high-quality, reliable products.

FAQ

1. What is silicone extrusion?

Silicone extrusion is a manufacturing process that involves pushing or pulling silicone rubber through a shaped die to create continuous profiles with specific cross-sections[1]. This method is used to produce various silicone products, such as tubes, seals, and custom profiles[3].

2. How does silicone extrusion work?

The silicone extrusion process begins with preparing the silicone compound and feeding it into an extruder[1]. The extruder then applies pressure to push the silicone through a die, which shapes the material into the desired profile[3]. The extruded silicone is then cured, cooled, and cut to the required lengths[3].

3. What are the advantages of silicone extrusion?

Silicone extrusion offers several advantages, including biocompatibility, chemical resistance, elastic memory, dielectric properties, and temperature resistance[1]. These properties make silicone extrusion suitable for various applications in industries such as medical, automotive, and food processing[1].

4. What equipment is used in silicone extrusion?

The primary equipment used in silicone extrusion includes an extruder, dies, heating and curing equipment, and cooling systems[5]. The extruder pushes the silicone through the die, which shapes the material[3]. Heating and curing equipment is used to strengthen the silicone, while cooling systems stabilize its shape[3].

5. What safety measures should be taken during silicone extrusion?

Safety measures during silicone extrusion include wearing safety goggles and gloves, ensuring proper machine maintenance, providing adequate ventilation, and having emergency procedures in place[5]. These precautions help to prevent accidents and ensure a safe working environment[5].

Citations:

[1] https://lgdsilicone.com/silicone-extrusion/

[2] https://www.weprofab.com/silicone-extrusion/

[3] https://elastostar.com/elastostars-silicone-rubber-extrusion-manufacturing-process/

[4] https://www.youtube.com/watch?v=v90r0H82xWw

[5] https://www.togohk.com/silicone-extrusion/

[6] https://seashorerubber.com/blog/what-is-the-silicone-rubber-extrusion-process/

[7] https://planetpropertyblog.co.uk/the-silicone-rubber-extrusion-process-explained/

[8] https://legenday.com.cn/micro-silicone-extrusion/

[9] https://www.biw.de/en/frontend/media/files/biw-silicone-extrusions-en.pdf

[10] https://www.vikingextrusions.co.uk/blog/our-silicone-rubber-extrusion-manufacturing-process/

[11] https://www.freudenbergmedical.com/en/what-we-offer/molding-extrusion/thermoplastic-and-silicone-extrusion/

[12] https://vav-group.com/silicone-extrusion-process-4/

[13] https://magazine.elkem.com/material-science-insights/what-is-the-silicone-rubber-extrusion-process/

[14] https://www.siliconerubberextrusions.co.uk/news/silicone-extrusions-the-product-design-and-tooling-process-explained/

[15] https://vav-group.com/de/silicone-extrusion-process-2/

[16] http://www.bharajmachineries.com/silicon.php

[17] https://www.youtube.com/watch?v=wK19IUvyk0k

[18] https://www.shutterstock.com/search/extrusion-machine

[19] https://www.youtube.com/watch?v=bF3j36qxeho

[20] https://stock.adobe.com/search/images?k=extrusion

[21] https://www.youtube.com/watch?v=GyZXC1kOK4k

[22] https://www.shutterstock.com/search/extrusion-equipment

[23] https://www.youtube.com/playlist?list=PLe6HcPyZQsM_7NOa21M9GRW-bNzIGbcsQ

[24] https://extrudedrubber.net/rubber-extrusions-gallery/