Content Menu

● Understanding the Role of an Aluminum Extrusion Die Corrector

● Earnings Overview

● Factors Influencing Salary

● Skills Required for Success

● Career Advancement Opportunities

● The Importance of Continuous Learning

● Work Environment

● Challenges Faced by Aluminum Extrusion Die Correctors

● Conclusion

● FAQ

>> 1. What qualifications do I need to become an aluminum extrusion die corrector?

>> 2. How does one gain experience as a die corrector?

>> 3. What are common challenges faced by aluminum extrusion die correctors?

>> 4. Is there a demand for aluminum extrusion die correctors?

>> 5. Can I work remotely as an aluminum extrusion die corrector?

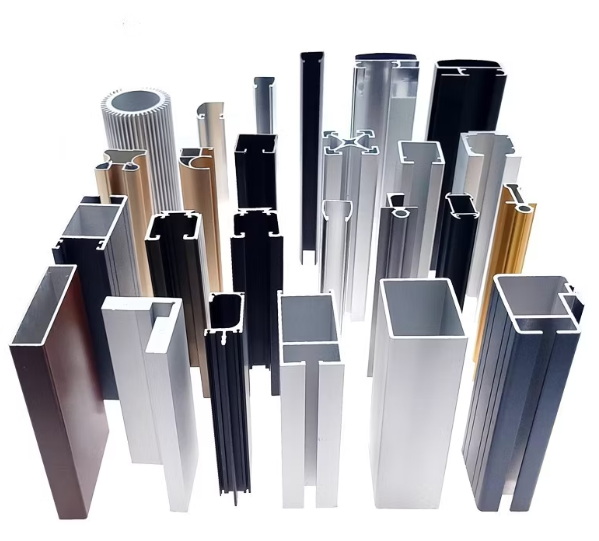

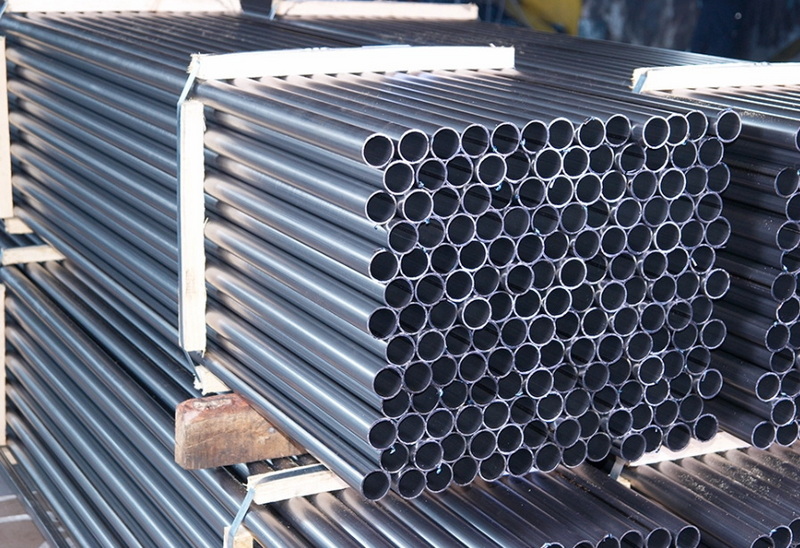

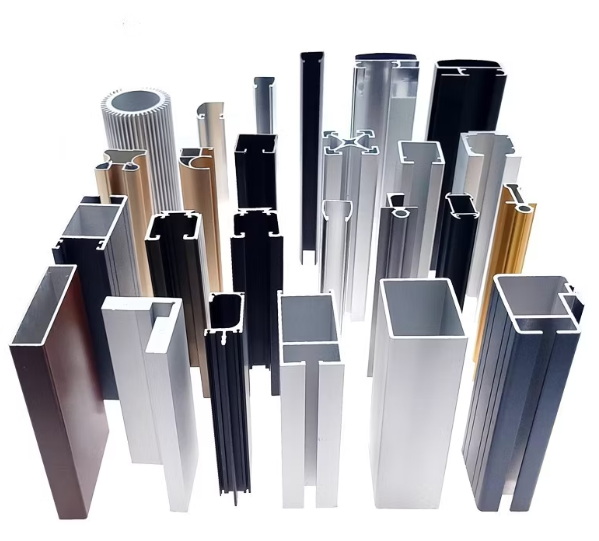

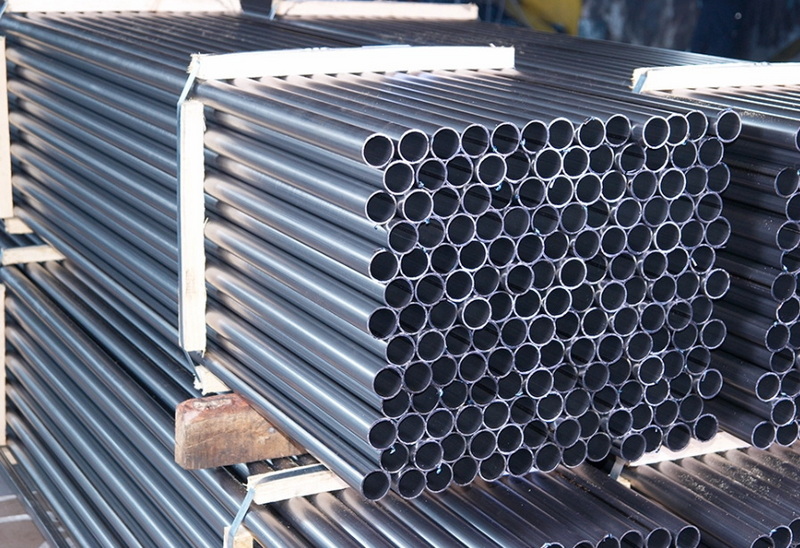

Aluminum extrusion is a vital manufacturing process used to create a wide range of products, from structural components to intricate designs. At the heart of this process lies the aluminum extrusion die, which shapes the aluminum as it is forced through under high pressure. The role of an "aluminum extrusion die corrector" is crucial in ensuring that these dies function correctly, leading to high-quality extrusions. This article delves into the earnings of aluminum extrusion die correctors, their job responsibilities, and the skills required for success in this field.

Understanding the Role of an Aluminum Extrusion Die Corrector

Job Responsibilities

An aluminum extrusion die corrector is responsible for maintaining and repairing dies used in the extrusion process. Their primary tasks include:

- Setup and Adjustment: Preparing dies for production runs and making necessary adjustments to ensure optimal performance.

- Repair and Maintenance: Conducting repairs on worn or damaged dies, which may involve grinding, polishing, or modifying die components.

- Quality Control: Inspecting extrusions for defects and ensuring that they meet specified tolerances. This includes measuring dimensions and checking surface finishes.

- Collaboration: Working closely with engineers and operators to troubleshoot issues and improve die performance. Effective communication is vital for identifying problems early in the production process.

- Documentation: Keeping detailed records of die modifications and performance metrics. This documentation helps in tracking improvements and understanding wear patterns over time.

Earnings Overview

The salary of an aluminum extrusion die corrector can vary significantly based on several factors, including experience, location, and the specific employer. Here's a breakdown of what you can expect:

- Entry-Level Positions: Newcomers to the field can expect to earn between $16 to $23 per hour. This translates to an annual salary range of approximately $33,280 to $47,840.

- Mid-Level Experience: With a few years of experience (typically 3-5 years), salaries can increase to around $25 to $35 per hour, resulting in annual earnings between $52,000 and $72,800.

- Senior Positions: Highly experienced die correctors or those in supervisory roles can command salaries upwards of $40 per hour, leading to annual incomes exceeding $83,200.

Factors Influencing Salary

Several factors influence how much an aluminum extrusion die corrector can earn:

- Location: Salaries tend to be higher in regions with a strong manufacturing presence or where the cost of living is elevated. For example, positions in metropolitan areas typically pay more than those in rural settings.

- Industry Demand: The demand for skilled workers in aluminum extrusion can drive salaries up. Industries such as automotive and aerospace often require high-quality extrusions, increasing the need for skilled die correctors.

- Company Size: Larger companies may offer better pay and benefits compared to smaller firms due to their capacity for larger production runs and greater financial resources.

Skills Required for Success

To excel as an aluminum extrusion die corrector, individuals must possess a combination of technical skills and practical experience:

- Technical Knowledge: Understanding the intricacies of die design and operation is essential. This includes knowledge of materials used in die manufacturing (like H13 steel) and processes like nitriding.

- Problem-Solving Skills: Die correctors must be adept at diagnosing issues with dies and extrusions and implementing effective solutions quickly. This often requires analytical thinking and creativity.

- Attention to Detail: Precision is critical in this role; even minor errors can lead to significant defects in extruded products. A meticulous approach ensures that all aspects of die correction are thoroughly addressed.

- Mechanical Aptitude: Familiarity with machinery used in the correction process is necessary. This includes tools for grinding, polishing, and measuring dies. Understanding how these machines operate can enhance efficiency during repairs.

Career Advancement Opportunities

As professionals gain experience in aluminum extrusion die correction, there are numerous opportunities for career advancement:

- Supervisory Roles: Experienced die correctors may move into supervisory positions overseeing teams of workers responsible for die maintenance and repair. Leadership skills become increasingly important at this level.

- Die Design Engineering: With additional training or education, some may transition into roles focused on designing new dies or improving existing designs. Knowledge of CAD software can be beneficial for this path.

- Quality Assurance Management: Those interested in quality control may pursue positions that focus on ensuring product standards are met throughout the manufacturing process. This role often involves developing quality control protocols.

The Importance of Continuous Learning

The field of aluminum extrusion is constantly evolving due to advancements in technology and materials science. To remain competitive, aluminum extrusion die correctors should engage in continuous learning:

- Training Programs: Many companies offer training programs that focus on new technologies or methodologies related to die correction.

- Certifications: Obtaining certifications related to machining or quality control can enhance job prospects and demonstrate commitment to professional development.

- Industry Conferences: Attending industry conferences allows professionals to network with peers, learn about new trends, and share best practices within the field.

Work Environment

The work environment for an aluminum extrusion die corrector typically involves:

- Manufacturing Facilities: Most work takes place in factories where aluminum extrusions are produced. These environments can be noisy due to machinery operation but are generally safe if proper protocols are followed.

- Team Collaboration: Die correctors often work as part of a team that includes engineers, operators, and quality control personnel. Effective communication within this team is key to identifying issues quickly.

- Hands-On Work: The role requires significant hands-on work with tools and machinery. Physical stamina is beneficial as tasks may involve lifting heavy components or standing for extended periods.

Challenges Faced by Aluminum Extrusion Die Correctors

While rewarding, the job also comes with its challenges:

- High Pressure Situations: Working under tight deadlines can create stress as production schedules must be met without compromising quality.

- Complex Problem Solving: Diagnosing issues with dies can be complex due to various factors affecting performance. Correcting these issues often requires innovative thinking.

- Keeping Up with Technology: As technology advances rapidly within manufacturing processes, staying updated on new tools and techniques is essential but can be overwhelming at times.

Conclusion

The role of an aluminum extrusion die corrector is both challenging and rewarding. With competitive salaries that increase with experience and skill development, this profession offers substantial opportunities for growth within the manufacturing sector. As industries continue to innovate and expand their use of aluminum extrusions, the demand for skilled die correctors will likely remain strong. Continuous learning and adaptation will be key factors for success in this dynamic field.

FAQ

1. What qualifications do I need to become an aluminum extrusion die corrector?

Typically, a high school diploma or equivalent is required. Additional training in machining or mechanical engineering can be beneficial. Experience in a manufacturing environment is also highly valued.

2. How does one gain experience as a die corrector?

Many start as apprentices or trainees in manufacturing settings where they can learn from experienced professionals while gaining hands-on experience with dies and machinery.

3. What are common challenges faced by aluminum extrusion die correctors?

Common challenges include managing wear on dies due to high-pressure conditions, ensuring consistent quality across production runs, and troubleshooting unexpected issues during the extrusion process.

4. Is there a demand for aluminum extrusion die correctors?

Yes, there is a steady demand for skilled workers in this field due to the ongoing need for aluminum products across various industries including automotive, construction, and aerospace.

5. Can I work remotely as an aluminum extrusion die corrector?

Most positions require on-site work due to the hands-on nature of the job involving machinery and equipment that cannot be operated remotely.