Content Menu

● Introduction to Aluminum Extrusion

>> Aluminum Extrusion Process

● Benefits of Aluminum Extrusion in Exercise Equipment

>> Applications in Exercise Equipment

● Design Considerations for Aluminum Exercise Equipment

>> Example: Aluminum Frame for Treadmill

>> Example: Aluminum Components in Exercise Bikes

● Production Challenges and Solutions

>> Example: Custom Die Design for Complex Shapes

● Conclusion

● FAQ

>> 1. What are the primary benefits of using aluminum extrusions in exercise equipment?

>> 2. How does the aluminum extrusion process enhance the durability of exercise equipment?

>> 3. Can aluminum extrusions be used for outdoor exercise equipment?

>> 4. How does aluminum extrusion contribute to the aesthetic appeal of exercise equipment?

>> 5. What role does aluminum extrusion play in reducing the weight of exercise equipment?

● Citations:

Aluminum extrusion plays a pivotal role in the production of exercise equipment due to its versatility, durability, and lightweight properties. This manufacturing process involves pushing aluminum alloy through a die to create specific shapes, which are ideal for various fitness applications. In this article, we will explore how aluminum extrusion is utilized in the production of exercise equipment, highlighting its benefits and applications.

Introduction to Aluminum Extrusion

Aluminum extrusion is a highly controlled process that transforms raw aluminum into functional profiles. It begins with die preparation, where high-strength steel dies are machined to match the desired cross-sectional profile and preheated to ensure smooth metal flow[1][2]. The aluminum billet is then preheated to make it malleable, and it is forced through the die using a hydraulic press[1][2].

Aluminum Extrusion Process

1. Die Preparation: The die is preheated to around 450-500°C to prevent sticking and ensure durability[1].

2. Billet Preheating: Aluminum billets are heated to 400-500°C to make them malleable[1][2].

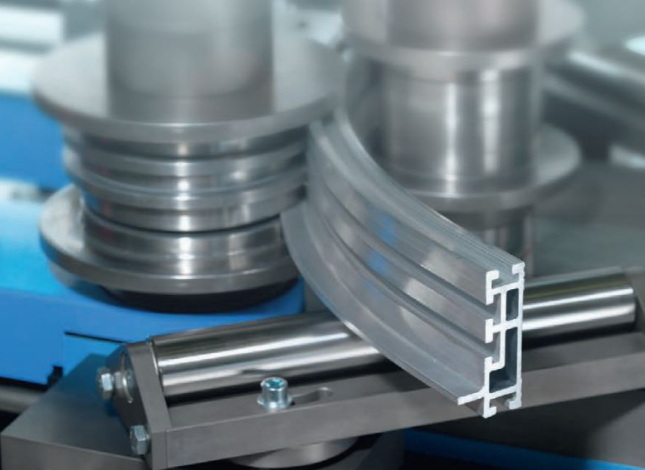

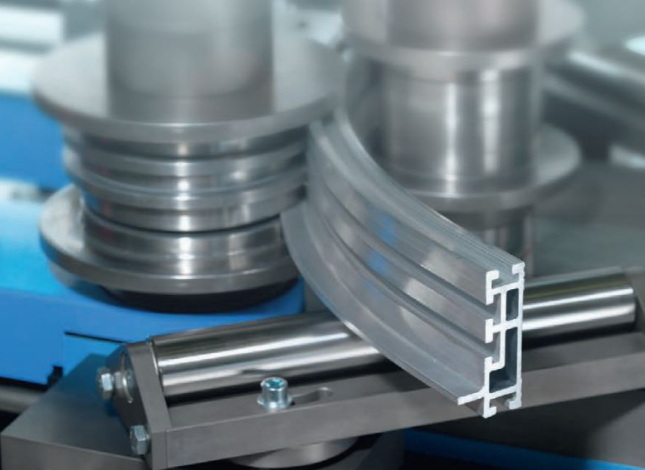

3. Extrusion: The billet is forced through the die using a hydraulic press, creating a continuous profile[1][2].

4. Quenching: The extruded profile is rapidly cooled to set its shape and enhance mechanical properties[1][2].

5. Stretching and Alignment: The extrusions are stretched to correct any twisting and ensure straightness[1][9].

6. Cutting to Length: Profiles are cut to specified lengths for further processing[1].

7. Secondary Operations: Additional treatments like anodizing or machining may be applied[1].

Benefits of Aluminum Extrusion in Exercise Equipment

Aluminum extrusions offer several advantages for exercise equipment:

- Lightweight and Durable: Aluminum is ideal for equipment that needs to be portable and withstand heavy use[3][7].

- Corrosion Resistance: Aluminum resists corrosion, ensuring equipment longevity even in humid environments[6][7].

- Customizable Designs: Complex shapes can be created to fit specific design needs, enhancing functionality and aesthetics[3][7].

- Thermal Properties: Aluminum's high thermal conductivity is beneficial for equipment requiring heat dissipation[3].

Applications in Exercise Equipment

Aluminum extrusions are used in various exercise equipment, including:

- Treadmills: Aluminum frames provide structural support while maintaining a lightweight design.

- Exercise Bikes: Aluminum components enhance durability and reduce vibration.

- Free Weights and Racks: Aluminum extrusions are used for weight racks due to their strength and corrosion resistance.

Design Considerations for Aluminum Exercise Equipment

When designing exercise equipment using aluminum extrusions, several factors are crucial:

- Structural Integrity: Ensuring that the extrusions provide sufficient support and stability.

- Aesthetic Appeal: Customizing shapes and finishes to enhance visual appeal.

- Cost-Effectiveness: Balancing design complexity with production costs.

Example: Aluminum Frame for Treadmill

Aluminum frames in treadmills are designed to be lightweight yet robust, ensuring stability during use. The extrusion process allows for complex shapes that can integrate with other components seamlessly.

Example: Aluminum Components in Exercise Bikes

Aluminum components in exercise bikes, such as the frame and handlebars, are designed to reduce weight while maintaining strength. This enhances user comfort and performance.

Production Challenges and Solutions

Producing exercise equipment with aluminum extrusions can present challenges, such as maintaining precise tolerances and ensuring structural integrity. Solutions include:

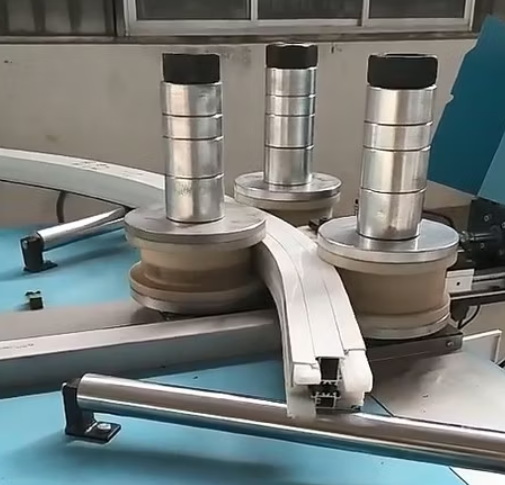

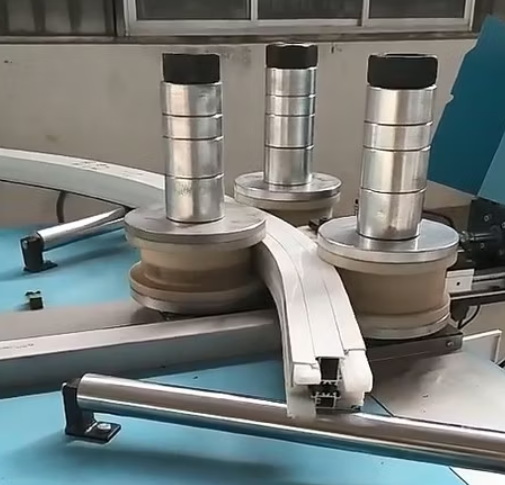

- Advanced Die Design: Utilizing sophisticated die designs to achieve complex shapes with high precision.

- Quality Control: Implementing rigorous quality control measures to ensure consistency in production.

Example: Custom Die Design for Complex Shapes

Custom dies allow for the creation of intricate shapes that meet specific design requirements. This flexibility is crucial for producing unique exercise equipment components.

Conclusion

Aluminum extrusion is a versatile and efficient method for producing exercise equipment. Its lightweight, durable, and corrosion-resistant properties make it an ideal material for various fitness applications. By understanding the aluminum extrusion process and its benefits, manufacturers can design and produce high-quality exercise equipment that meets both functional and aesthetic needs.

FAQ

1. What are the primary benefits of using aluminum extrusions in exercise equipment?

Aluminum extrusions offer a high strength-to-weight ratio, corrosion resistance, and customizability, making them ideal for exercise equipment that requires durability and portability[3][7].

2. How does the aluminum extrusion process enhance the durability of exercise equipment?

The extrusion process allows for the creation of complex shapes with precise dimensions, ensuring structural integrity. Additionally, aluminum's natural corrosion resistance extends the lifespan of equipment[3][6].

3. Can aluminum extrusions be used for outdoor exercise equipment?

Yes, aluminum extrusions are suitable for outdoor equipment due to their corrosion resistance, which protects them from environmental factors like rain and humidity[6][7].

4. How does aluminum extrusion contribute to the aesthetic appeal of exercise equipment?

Aluminum extrusions can be anodized or coated to enhance their appearance, allowing for a wide range of colors and finishes that improve the visual appeal of exercise equipment[1][3].

5. What role does aluminum extrusion play in reducing the weight of exercise equipment?

Aluminum extrusions are significantly lighter than other metals like steel, making them ideal for reducing the overall weight of exercise equipment without compromising strength[3][7].

Citations:

[1] https://hitopindustrial.com/aluminum-extrusion-process/

[2] https://shop.machinemfg.com/aluminum-extrusion-process-a-detailed-breakdown/

[3] https://www.renxin-precision.com/blogs-detail/-28

[4] https://www.alamy.com/stock-photo/aluminium-extrusion.html

[5] https://www.youtube.com/watch?v=iiGlq7408ME

[6] https://kundel.com/some-interesting-facts-about-using-aluminum-extrusion/

[7] https://www.odmetals.com/blog/enhancing-sports-equipment-and-outdoor-adventure-with-custom-aluminum-extrusions

[8] https://www.howardprecision.com/the-advantages-of-aluminum-extruded-products/

[9] https://aec.org/faqs

[10] https://aec.org/extrusion-equipment

[11] https://aec.org/consumer

[12] https://www.lametals.co.uk/blog/what-is-aluminium-extrusion/

[13] https://www.kloecknermetals.com/blog/what-are-aluminum-extrusions/

[14] https://www.yuhfield.net/en/news/industry/what-are-aluminum-extrusions-2

[15] https://leadrp.net/pt/blog/a-complete-guide-to-aluminum-extrusion/

[16] https://rpmindinc.com/the-role-of-extruded-aluminum-shapes-in-daily-life/

[17] https://leadrp.net/blog/a-complete-guide-to-aluminum-extrusion/

[18] https://www.extmet.com/en/extrusion-2/

[19] https://www.tensilemillcnc.com/blog/the-most-efficient-aluminum-extrusion-process-with-precise-quality-control-will-guarantee-the-best-results-of-your-production

[20] https://www.linkedin.com/pulse/aluminum-profile-extrusion-process-precautions-mataluminum-ikyoc

[21] https://ca.pinterest.com/dimtri_p/aluminum-extrusion/

[22] https://www.freepik.com/free-photos-vectors/aluminum-extrusion/74

[23] https://www.istockphoto.com/photos/aluminum-extrusion

[24] https://www.shutterstock.com/search/extrusion-equipment

[25] https://www.istockphoto.com/photos/aluminium-extrusion

[26] https://www.shutterstock.com/search/aluminium-extrusion

[27] https://www.shutterstock.com/video/search/aluminum-extrusion

[28] https://stock.adobe.com/search?k=%22aluminium+extrusion%22

[29] https://www.youtube.com/watch?v=pyqQhTDcKbA

[30] https://www.shutterstock.com/search/extrusion-press

[31] https://www.digikey.ch/en/videos/w/wakefield-vette/aluminum-extrusion-press-watch-wakefield-solutions-aluminum-being-extruded

[32] https://stock.adobe.com/search/images?k=%22aluminium+extrusion%22

[33] https://apelextrusions.com/video/

[34] https://parco-inc.com/training-videos/