Content Menu

● Understanding Aluminum Extrusion Drawer Slides

>> Benefits of Using Aluminum Extrusion Drawer Slides

● Tools and Materials Needed

● Step-by-Step Installation Guide

>> Step 1: Measure and Mark

>> Step 2: Prepare the Drawer Slides

>> Step 3: Attach the Rail to the Cabinet

>> Step 4: Attach the Slide to the Drawer

>> Step 5: Insert the Drawer

● Tips for Successful Installation

● Common Mistakes to Avoid

● Maintenance Tips for Longevity

● Alternative Applications of Aluminum Extrusion Drawer Slides

● Conclusion

● FAQ

>> 1. What are aluminum extrusion drawer slides?

>> 2. Do I need special tools for installation?

>> 3. Can I install these slides on any type of cabinet?

>> 4. How do I maintain aluminum extrusion drawer slides?

>> 5. Are there different types of aluminum extrusion drawer slides?

● Citations:

Installing aluminum extrusion drawer slides can be a straightforward and rewarding project, whether you're building custom furniture, organizing your workshop, or creating storage solutions for your van. This guide will walk you through the installation process step-by-step, providing tips, visual aids, and videos to ensure your success.

Understanding Aluminum Extrusion Drawer Slides

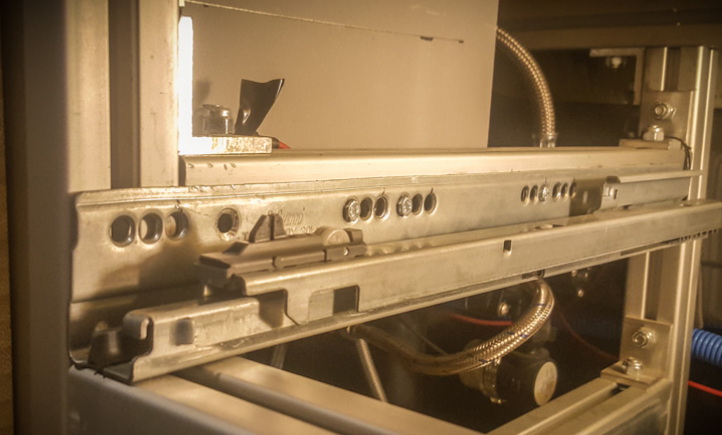

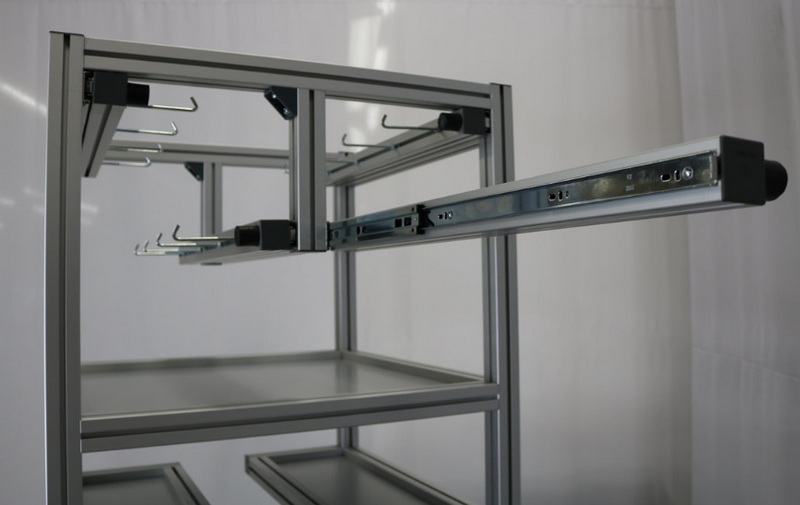

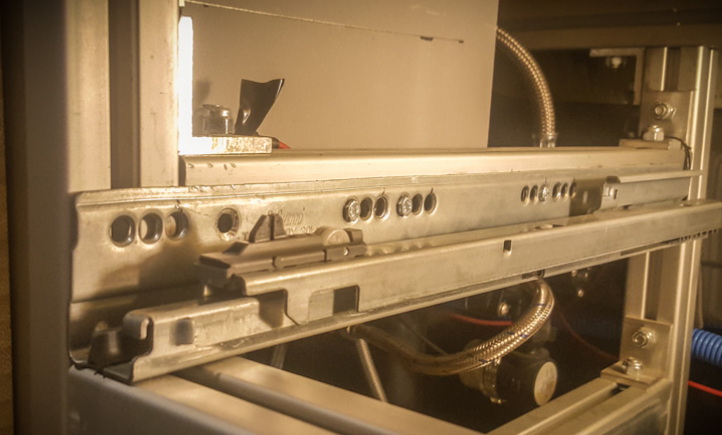

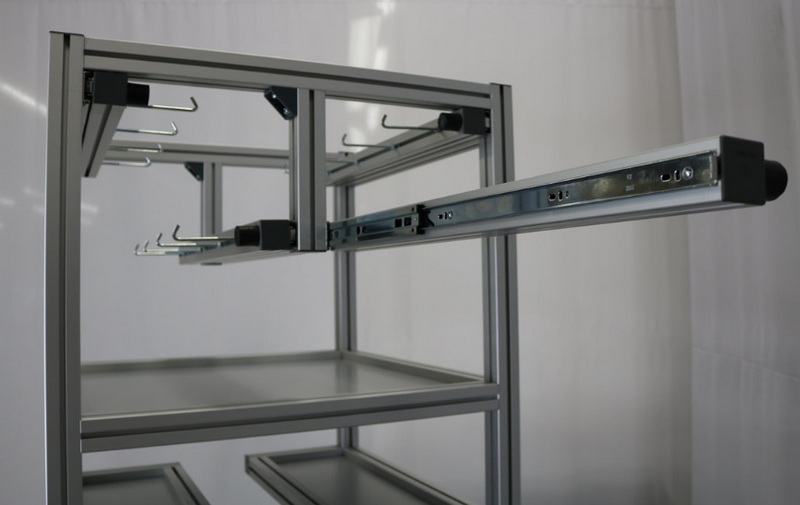

Aluminum extrusion drawer slides are designed to provide smooth and efficient sliding action for drawers. They are commonly used in various applications due to their durability, lightweight nature, and ease of installation. These slides typically consist of two main components: the rail that attaches to the cabinet or frame and the slide that attaches to the drawer itself.

Benefits of Using Aluminum Extrusion Drawer Slides

- Durability: Aluminum is resistant to rust and corrosion, making it ideal for various environments.

- Lightweight: Compared to traditional materials, aluminum reduces the overall weight of your drawers.

- Customizability: The modular nature of aluminum extrusions allows for easy adjustments and modifications.

- Smooth Operation: High-quality ball-bearing mechanisms ensure that drawers slide in and out effortlessly.

- Versatility: Aluminum extrusion drawer slides can be used in a wide range of applications, from kitchen cabinets to industrial workstations.

Tools and Materials Needed

Before starting the installation process, gather the following tools and materials:

- Aluminum extrusion drawer slides

- Drill with drill bits

- Screwdriver

- Measuring tape

- Level

- T-nuts (specific to your aluminum extrusion profile)

- Bolts (matching the T-nuts)

- Safety goggles

- Clamps (optional but recommended for stability)

- Sandpaper (for smoothing edges)

Step-by-Step Installation Guide

Step 1: Measure and Mark

Begin by measuring the space where you plan to install the drawer slides.

- Use a measuring tape to determine the height at which you want to mount the slides.

- Mark this height on both sides of the cabinet or frame using a pencil.

Step 2: Prepare the Drawer Slides

Separate the two parts of your aluminum extrusion drawer slides.

- Identify which part will be attached to the cabinet (the rail) and which part will be attached to the drawer (the slide).

Step 3: Attach the Rail to the Cabinet

Using your marked lines as a guide:

1. Align the bottom edge of the rail with your marks.

2. Use a level to ensure it is straight before marking where you will drill holes.

3. Pre-drill holes for your screws or bolts based on the pre-drilled holes in your rail.

4. Insert T-nuts into the aluminum extrusion if necessary, then secure the rail with bolts.

Step 4: Attach the Slide to the Drawer

Now it's time to attach the slide to your drawer:

1. Position the slide so that its front edge is flush with the front of the drawer.

2. Mark where you will drill holes for securing it.

3. Pre-drill these holes and attach using screws or bolts.

Step 5: Insert the Drawer

With both parts of the drawer slides attached, it's time to insert the drawer into its designated space:

1. Align the ends of the slides attached to the drawer with those mounted in the cabinet.

2. Gently push in until they engage fully.

3. Test by pulling out and pushing in several times to ensure smooth operation.

Tips for Successful Installation

- Check Alignment: Always double-check that everything is level before securing any components.

- Use Quality Hardware: Ensure that you are using high-quality T-nuts and screws designed for aluminum extrusions.

- Test Fit Before Finalizing: Before tightening all bolts completely, test fit everything to ensure smooth operation.

- Clamp for Stability: If you're working alone, consider using clamps to hold components in place while you drill or screw them together.

Common Mistakes to Avoid

When installing aluminum extrusion drawer slides, there are several common pitfalls that can lead to frustration or poor performance:

- Misalignment: Failing to align both parts of the slide properly can lead to binding or uneven wear over time.

- Over-tightening Screws: While it's important to secure components firmly, over-tightening can strip threads or deform aluminum profiles.

- Ignoring Weight Limits: Each type of slide has a specific weight capacity; exceeding this can cause failure or damage over time.

Maintenance Tips for Longevity

To ensure that your aluminum extrusion drawer slides continue to operate smoothly over time, consider these maintenance tips:

- Regular Cleaning: Dust and debris can accumulate in tracks; regularly wipe them down with a damp cloth or vacuum them out.

- Lubrication: Occasionally apply a silicone-based lubricant along tracks and rollers for enhanced performance without attracting dirt.

- Inspect Regularly: Periodically check for signs of wear or damage; addressing issues early can prevent more significant problems later on.

Alternative Applications of Aluminum Extrusion Drawer Slides

Aluminum extrusion drawer slides are not limited solely to traditional cabinetry; they have various alternative applications:

- Workshop Storage Solutions: Use them in tool chests or cabinets where heavy tools need easy access while maintaining organization.

- Mobile Workstations: Perfect for creating drawers in mobile workstations where space is limited but functionality is crucial.

- Van Conversions: Ideal for van builds where lightweight yet durable storage solutions are necessary for efficient use of space.

Conclusion

Installing aluminum extrusion drawer slides is an accessible project that can enhance both functionality and aesthetics in various applications. With proper measurements, quality materials, and attention to detail, you can achieve a professional-looking installation that operates smoothly for years to come. The versatility of these slides allows them not only in home improvement projects but also in creative solutions across different fields such as automotive conversions and workshop setups.

FAQ

1. What are aluminum extrusion drawer slides?

Aluminum extrusion drawer slides are sliding mechanisms made from aluminum profiles that allow drawers to open and close smoothly within cabinets or frames.

2. Do I need special tools for installation?

While basic tools like a drill, screwdriver, and measuring tape are necessary, no special tools are required beyond what is typically found in a home workshop.

3. Can I install these slides on any type of cabinet?

Yes, aluminum extrusion drawer slides can be installed on various types of cabinets as long as there is sufficient space and proper mounting points available.

4. How do I maintain aluminum extrusion drawer slides?

Regularly clean them with a damp cloth and check for any debris in the tracks that may impede smooth operation.

5. Are there different types of aluminum extrusion drawer slides?

Yes, there are various types available depending on load capacity, extension length (full extension vs. partial), and mounting styles (side-mounted vs. bottom-mounted).

Citations:

[1] https://engineerswhovanlife.com/8020-van-galley-drawers/

[2] https://www.youtube.com/watch?v=A4IYXQp0SlU

[3] https://www.youtube.com/watch?v=ayzEibdlz0g

[4] https://ourkaravan.com/attaching-cabinet-hardware-to-8020/

[5] https://www.youtube.com/watch?v=GR1VQAgntxQ

[6] https://www.youtube.com/watch?v=-ruIsv6D8Bg

[7] https://vadania.com/how-to-install-drawer-slides-step-by-step-with-photos/

[8] https://www.youtube.com/watch?v=U7C-DwRVwLI

[9] https://www.youtube.com/watch?v=BQbeCCU6o9k