Content Menu

● The Nature of Aluminum Extrusion Plates

● Inherent Properties Contributing to Durability

>> Corrosion Resistance

>> Strength-to-Weight Ratio

● Enhancing Durability Through Surface Treatments

>> Anodizing

>> Powder Coating

● Weather Resistance and Thermal Properties

>> UV Resistance

>> Thermal Efficiency

● Applications Showcasing Durability

>> Architectural Facades

>> Outdoor Furniture

>> Signage and Displays

● Maintenance Considerations

● Environmental Impact and Sustainability

● Challenges and Considerations

>> Galvanic Corrosion

>> Extreme Environments

● Innovations in Aluminum Extrusion Plate Technology

● Conclusion

● FAQ

>> 1. How long can aluminum extrusion plates last in outdoor environments?

>> 2. Are aluminum extrusion plates suitable for coastal environments?

>> 3. Can aluminum extrusion plates withstand extreme temperature fluctuations?

>> 4. How do aluminum extrusion plates compare to other materials in terms of outdoor durability?

>> 5. What maintenance is required to ensure the longevity of aluminum extrusion plates outdoors?

● Citations:

Aluminum extrusion plates have become increasingly popular in various outdoor applications due to their exceptional durability and versatility. From architectural facades to outdoor furniture, these plates offer a unique combination of strength, lightweight properties, and resistance to environmental factors. In this comprehensive article, we'll explore the durability of aluminum extrusion plates for outdoor use, examining their properties, benefits, and considerations for optimal performance.

The Nature of Aluminum Extrusion Plates

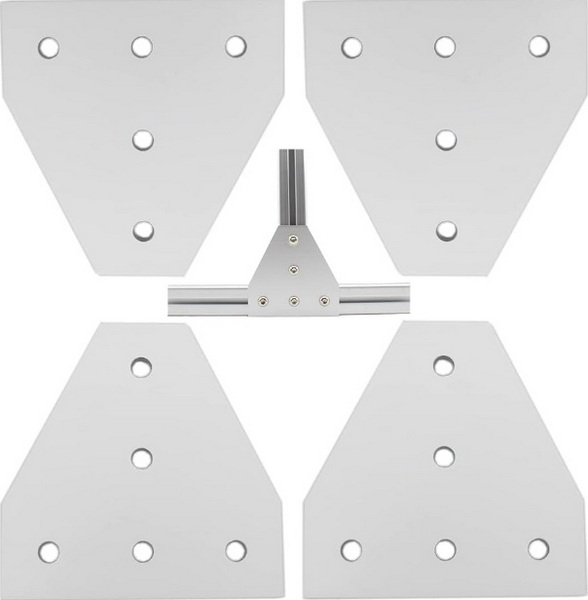

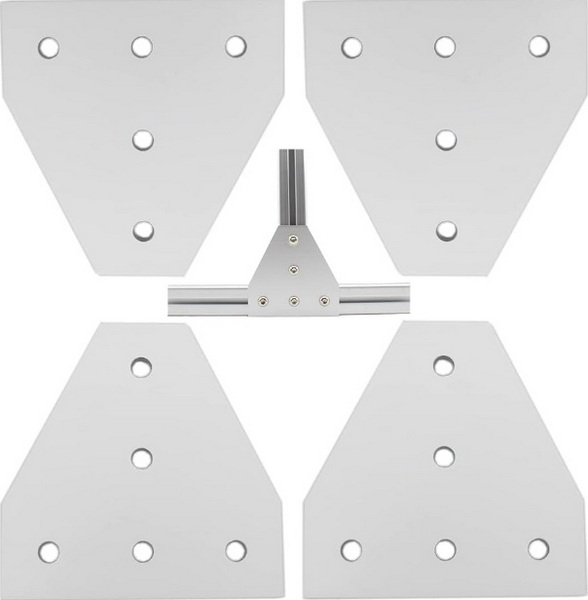

Aluminum extrusion plates are created through a process where aluminum alloy is forced through a die to create specific shapes and profiles. This manufacturing technique allows for the production of plates with custom designs and intricate details, making them ideal for a wide range of outdoor applications[1].

Inherent Properties Contributing to Durability

Corrosion Resistance

One of the most significant advantages of aluminum extrusion plates is their natural corrosion resistance. When exposed to air, aluminum forms a thin, protective oxide layer on its surface, which acts as a barrier against corrosion[3]. This inherent property makes aluminum extrusion plates particularly suitable for outdoor environments where they may be exposed to moisture, humidity, and other corrosive elements.

Strength-to-Weight Ratio

Aluminum extrusion plates boast an exceptional strength-to-weight ratio, making them both robust and lightweight[4]. This characteristic is crucial for outdoor applications where structural integrity is essential, but excessive weight could pose challenges. The combination of strength and lightness allows for easier installation and reduced stress on supporting structures.

Enhancing Durability Through Surface Treatments

While aluminum extrusion plates are naturally durable, various surface treatments can further enhance their resistance to outdoor elements and extend their lifespan.

Anodizing

Anodizing is an electrochemical process that creates a hard, durable oxide layer on the surface of aluminum extrusion plates[5]. This treatment not only improves corrosion resistance but also allows for coloration, providing aesthetic options while maintaining durability. For outdoor applications, a minimum of 25-micron anodization is recommended to ensure optimal protection against environmental factors[3].

Powder Coating

Powder coating is another popular surface treatment for aluminum extrusion plates used outdoors. This process involves applying a dry powder to the surface, which is then cured under heat to form a hard, durable finish. Powder coating offers excellent resistance to UV radiation, moisture, and abrasion, making it ideal for outdoor use[6].

Weather Resistance and Thermal Properties

Aluminum extrusion plates exhibit remarkable weather resistance, making them suitable for a wide range of outdoor environments. Their ability to withstand UV radiation, temperature fluctuations, and moisture contributes to their long-term durability[2].

UV Resistance

Unlike many materials that degrade when exposed to sunlight, aluminum extrusion plates maintain their structural integrity and appearance even after prolonged UV exposure. This property is particularly valuable for outdoor applications where aesthetics and longevity are crucial.

Thermal Efficiency

Aluminum extrusion plates also offer excellent thermal properties, which can be advantageous in outdoor settings. Their ability to conduct heat efficiently helps in managing temperature variations, reducing the risk of thermal stress and potential damage[4].

Applications Showcasing Durability

The durability of aluminum extrusion plates is evident in their widespread use across various outdoor applications:

Architectural Facades

Aluminum extrusion plates are frequently used in building facades, where they must withstand constant exposure to the elements. Their corrosion resistance and ability to maintain appearance over time make them an excellent choice for long-lasting architectural designs[1].

Outdoor Furniture

The lightweight nature and weather resistance of aluminum extrusion plates make them ideal for outdoor furniture. From patio sets to public benches, these plates provide durability without compromising on style or comfort.

Signage and Displays

Outdoor signage and displays benefit from the durability of aluminum extrusion plates. Their resistance to weathering ensures that signs remain legible and structurally sound for extended periods, even in harsh environments.

Maintenance Considerations

While aluminum extrusion plates are highly durable, proper maintenance can further extend their lifespan and preserve their appearance:

1. Regular Cleaning: Periodic cleaning with mild soap and water can remove dirt and pollutants that may accumulate on the surface.

2. Inspection: Regular inspections can help identify any signs of wear or damage early, allowing for timely repairs or maintenance.

3. Reapplication of Protective Coatings: Depending on the environment and usage, reapplying protective coatings may be necessary to maintain optimal durability.

Environmental Impact and Sustainability

The durability of aluminum extrusion plates contributes to their sustainability. Their long lifespan reduces the need for frequent replacements, minimizing waste and resource consumption. Additionally, aluminum is 100% recyclable without loss of quality, making it an environmentally friendly choice for outdoor applications[5].

Challenges and Considerations

While aluminum extrusion plates offer excellent durability for outdoor use, there are some challenges and considerations to keep in mind:

Galvanic Corrosion

When in contact with certain metals, aluminum can be susceptible to galvanic corrosion. Proper design and the use of appropriate fasteners and isolation techniques can mitigate this risk[7].

Extreme Environments

In particularly harsh environments, such as coastal areas with high salt content in the air, additional protective measures may be necessary to ensure the longevity of aluminum extrusion plates.

Innovations in Aluminum Extrusion Plate Technology

Ongoing research and development in aluminum alloys and extrusion techniques continue to improve the durability and performance of aluminum extrusion plates for outdoor use. Advancements in alloy compositions and surface treatments are pushing the boundaries of what can be achieved with these versatile materials[2].

Conclusion

Aluminum extrusion plates have proven to be exceptionally durable for outdoor use, offering a combination of corrosion resistance, strength, and versatility that makes them suitable for a wide range of applications. Their natural properties, enhanced by various surface treatments, allow them to withstand the challenges of outdoor environments while maintaining their structural integrity and appearance.

The durability of aluminum extrusion plates not only ensures long-lasting performance but also contributes to sustainability by reducing the need for frequent replacements and offering full recyclability. As technology continues to advance, we can expect even greater improvements in the durability and functionality of aluminum extrusion plates, further solidifying their position as a preferred material for outdoor applications.

By understanding the properties, benefits, and considerations associated with aluminum extrusion plates, designers, architects, and engineers can make informed decisions to leverage these materials effectively in their outdoor projects, ensuring longevity, aesthetics, and performance.

FAQ

1. How long can aluminum extrusion plates last in outdoor environments?

Aluminum extrusion plates can last for decades in outdoor environments when properly treated and maintained. Their lifespan depends on factors such as the specific alloy used, surface treatments applied, and the severity of environmental conditions. With appropriate care, it's not uncommon for aluminum extrusion plates to remain functional and aesthetically pleasing for 20-30 years or more in outdoor applications.

2. Are aluminum extrusion plates suitable for coastal environments?

Yes, aluminum extrusion plates can be suitable for coastal environments, but additional precautions may be necessary. The high salt content in coastal air can accelerate corrosion, so using marine-grade aluminum alloys and applying robust protective coatings is crucial. Regular maintenance, including frequent cleaning to remove salt deposits, is also important to ensure longevity in these challenging environments.

3. Can aluminum extrusion plates withstand extreme temperature fluctuations?

Aluminum extrusion plates have excellent thermal properties that allow them to withstand significant temperature fluctuations. The material's ability to expand and contract uniformly helps prevent warping or distortion. However, in extreme cases, proper design considerations, such as allowing for thermal expansion in joints and connections, are important to prevent stress on the structure.

4. How do aluminum extrusion plates compare to other materials in terms of outdoor durability?

Aluminum extrusion plates generally offer superior durability compared to many other materials used outdoors. They are more corrosion-resistant than steel, more durable than wood or plastic, and lighter than most alternatives while maintaining comparable strength. Their resistance to UV radiation and weathering also gives them an advantage over many synthetic materials in long-term outdoor applications.

5. What maintenance is required to ensure the longevity of aluminum extrusion plates outdoors?

To maintain the longevity of aluminum extrusion plates outdoors, regular cleaning with mild soap and water is recommended to remove dirt and pollutants. Periodic inspections should be conducted to check for any signs of wear or damage. Depending on the environment and surface treatment, reapplication of protective coatings may be necessary every few years. In harsh environments, more frequent maintenance may be required to preserve the plates' durability and appearance.

Citations:

[1] https://www.odmetals.com/blog/enhancing-sports-equipment-and-outdoor-adventure-with-custom-aluminum-extrusions

[2] https://www.yjing-extrusion.com/how-can-aluminum-extrusion-mounting-improve-your-project-s-durability.html

[3] https://www.linkedin.com/pulse/advantages-aluminum-extrusion-process-

[4] https://simmal.com/exploring-the-strength-of-aluminium-profiles-for-outdoor-applications/

[5] https://www.howardprecision.com/benefits-of-aluminum-extrusions/

[6] https://www.alineautomation.com/6-types-finishes-to-consider-your-aluminum-extrusions/

[7] https://www.chaluminium.com/optimizing-aluminum-plate-design-a-comprehensive-guide