Content Menu

● Introduction

● Understanding 80/20 Aluminum Extrusion Profiles

● Strength Comparison: Aluminum vs. Steel

>> 1. Tensile Strength

>> 2. Strength-to-Weight Ratio

>> 3. Corrosion Resistance

>> 4. Flexibility and Ductility

● Advantages of 80/20 Aluminum Extrusion Profiles

>> 1. Modularity and Flexibility

>> 2. Lightweight

>> 3. No Welding Required

>> 4. Cost-Effective

● Applications of 80/20 Aluminum Extrusion Profiles

● Structural Considerations

>> 1. Profile Selection

>> 2. Connection Methods

>> 3. Load Distribution

● Case Studies: 80/20 Aluminum vs. Steel

>> Machine Frames

>> Workstations

>> Automotive Applications

● Limitations of 80/20 Aluminum Extrusion Profiles

● Future Trends

● Conclusion

● FAQ

>> 1. Are 80/20 aluminum extrusion profiles strong enough for industrial applications?

>> 2. How does the cost of 80/20 aluminum extrusion profiles compare to steel?

>> 3. Can 80/20 aluminum extrusion profiles be used outdoors?

>> 4. How easy is it to modify structures built with 80/20 aluminum extrusion profiles?

>> 5. Can 80/20 aluminum extrusion profiles be combined with steel components?

● Citations:

Introduction

When it comes to structural materials for industrial, commercial, and DIY applications, the debate between aluminum extrusion profiles and steel has been ongoing. 80/20 aluminum extrusion, in particular, has gained significant popularity due to its versatility, lightweight nature, and ease of use. But how does it really stack up against steel in terms of strength? This comprehensive article will explore the strengths and characteristics of 80/20 aluminum extrusion profiles compared to steel, helping you make an informed decision for your next project.

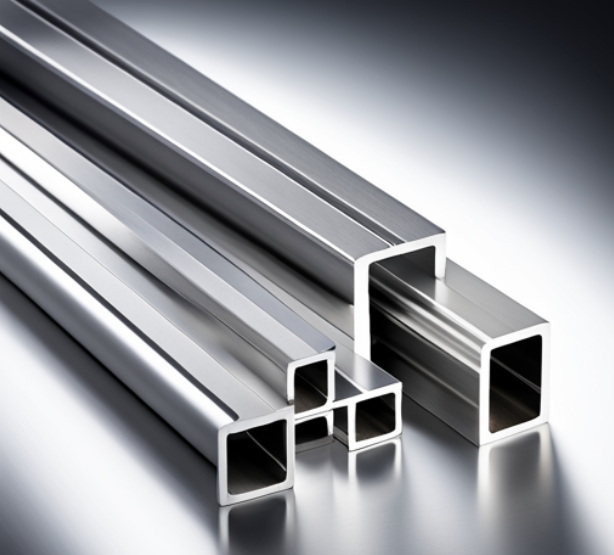

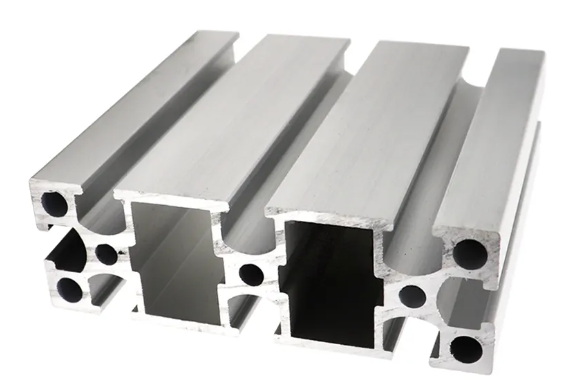

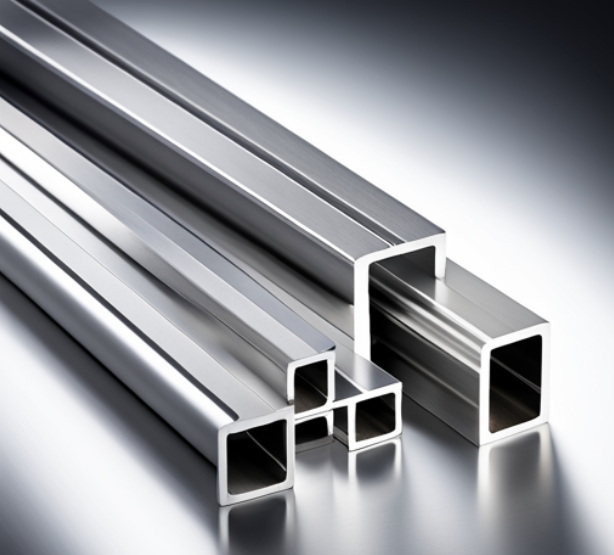

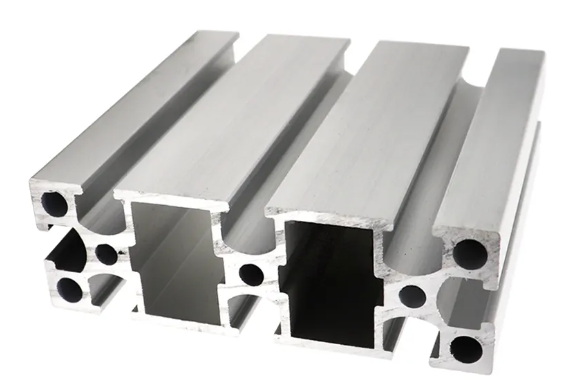

Understanding 80/20 Aluminum Extrusion Profiles

80/20 aluminum extrusion profiles are modular framing systems made from high-quality aluminum alloy. The name "80/20" comes from the company that invented and patented this system, claiming that their product can be used to build structures that are 80% complete in 20% of the time compared to traditional methods[6].

These profiles feature T-shaped grooves running along their length, allowing for easy attachment of various components and accessories. This design provides flexibility and modularity, making 80/20 profiles popular in many applications, from industrial machinery to home DIY projects.

Strength Comparison: Aluminum vs. Steel

When comparing the strength of 80/20 aluminum extrusion profiles to steel, several factors come into play:

1. Tensile Strength

Steel generally has a higher tensile strength than aluminum. For example, mild steel has a tensile strength of about 400 MPa, while 6061-T6 aluminum (commonly used in 80/20 profiles) has a tensile strength of about 310 MPa[2]. However, this doesn't tell the whole story.

2. Strength-to-Weight Ratio

While steel is stronger in absolute terms, aluminum shines when it comes to strength-to-weight ratio. Aluminum is about one-third the weight of steel, meaning that for the same weight, an aluminum structure can often be stronger than a steel one[1].

3. Corrosion Resistance

Aluminum naturally forms a protective oxide layer, making it highly resistant to corrosion. Steel, on the other hand, requires additional treatments or coatings to prevent rust and corrosion[8].

4. Flexibility and Ductility

Aluminum is more ductile than steel, allowing it to bend without breaking. This property can be advantageous in applications where some flexibility is desired[2].

Advantages of 80/20 Aluminum Extrusion Profiles

80/20 aluminum extrusion profiles offer several advantages that make them a compelling choice for many applications:

1. Modularity and Flexibility

The T-slot design of 80/20 profiles allows for easy assembly, disassembly, and reconfiguration. This modularity is a significant advantage over welded steel structures, which are typically permanent[3].

2. Lightweight

The lightweight nature of aluminum makes 80/20 profiles easier to handle, transport, and install compared to steel structures[1].

3. No Welding Required

Unlike steel structures, which often require welding, 80/20 profiles can be assembled using simple tools. This reduces the need for specialized skills and equipment[1].

4. Cost-Effective

While the initial cost of aluminum may be higher than steel, the ease of assembly and potential for reuse can make 80/20 profiles more cost-effective in the long run[5].

Applications of 80/20 Aluminum Extrusion Profiles

80/20 aluminum extrusion profiles find use in a wide range of applications, including:

1. Industrial machinery frames

2. Workstations and ergonomic solutions

3. Trade show displays

4. Robotics and automation systems

5. DIY projects (e.g., 3D printer frames, sim racing rigs)

Structural Considerations

When designing structures using 80/20 aluminum extrusion profiles, several factors should be considered:

1. Profile Selection

80/20 offers various profile series (10-series, 15-series, etc.) with different sizes and strengths. Choosing the right profile for your application is crucial[9].

2. Connection Methods

The strength of an 80/20 structure largely depends on the connection methods used. Proper fasteners and brackets are essential for maximizing structural integrity[12].

3. Load Distribution

Proper design and load distribution can help aluminum structures match or exceed the performance of steel in many applications.

Case Studies: 80/20 Aluminum vs. Steel

Let's look at some real-world comparisons between 80/20 aluminum extrusion profiles and steel:

Machine Frames

In many industrial applications, 80/20 aluminum frames have successfully replaced steel frames. The modularity of 80/20 profiles allows for easier modifications and upgrades, while their lightweight nature reduces overall machine weight without compromising structural integrity.

Workstations

80/20 aluminum profiles are increasingly popular for building ergonomic workstations. Their adjustability and ease of reconfiguration offer advantages over traditional steel workbenches, allowing for quick adaptation to different tasks or users.

Automotive Applications

In the automotive industry, where weight reduction is crucial for fuel efficiency, aluminum extrusions are often preferred over steel. While not always using 80/20 specifically, this trend demonstrates the strength and viability of aluminum in high-stress applications.

Limitations of 80/20 Aluminum Extrusion Profiles

While 80/20 aluminum extrusion profiles offer many advantages, they do have some limitations compared to steel:

1. Lower absolute strength

2. Higher initial cost

3. Lower heat resistance

4. Potential for galvanic corrosion when in contact with certain metals

Future Trends

As material science advances, we can expect to see continued improvements in aluminum alloys, potentially narrowing the strength gap with steel even further. Additionally, hybrid designs combining the strengths of both aluminum and steel may become more common in complex applications.

Conclusion

In comparing the strength of 80/20 aluminum extrusion profiles to steel, it's clear that each material has its strengths and ideal applications. While steel may have higher absolute strength, the lightweight nature, corrosion resistance, and modularity of 80/20 aluminum profiles make them a superior choice for many applications.

The key to success lies in understanding the specific requirements of your project and choosing the material that best meets those needs. In many cases, the versatility, ease of use, and long-term cost-effectiveness of 80/20 aluminum extrusion profiles can outweigh the raw strength advantage of steel.

As we continue to push the boundaries of material science and engineering, it's likely that aluminum extrusion profiles will play an increasingly important role in structural applications, offering a perfect balance of strength, weight, and flexibility.

FAQ

1. Are 80/20 aluminum extrusion profiles strong enough for industrial applications?

Yes, 80/20 aluminum extrusion profiles are strong enough for many industrial applications. While they may not match the absolute strength of steel, their high strength-to-weight ratio and modular design make them suitable for a wide range of industrial uses, including machine frames, workstations, and automation systems.

2. How does the cost of 80/20 aluminum extrusion profiles compare to steel?

Initially, 80/20 aluminum extrusion profiles may be more expensive than steel. However, when considering the total cost of ownership, including ease of assembly, potential for reuse, and lower transportation costs due to lighter weight, 80/20 profiles can be more cost-effective in the long run.

3. Can 80/20 aluminum extrusion profiles be used outdoors?

Yes, 80/20 aluminum extrusion profiles can be used outdoors. Aluminum naturally forms a protective oxide layer that makes it highly resistant to corrosion, making it suitable for outdoor applications. However, for extreme environments, additional protective coatings may be recommended.

4. How easy is it to modify structures built with 80/20 aluminum extrusion profiles?

Structures built with 80/20 aluminum extrusion profiles are very easy to modify. The T-slot design allows for easy addition or removal of components without the need for welding or specialized tools. This modularity is one of the key advantages of 80/20 profiles over traditional steel structures.

5. Can 80/20 aluminum extrusion profiles be combined with steel components?

Yes, 80/20 aluminum extrusion profiles can be combined with steel components in many applications. However, care must be taken to avoid galvanic corrosion when these metals are in direct contact. Using appropriate fasteners and, if necessary, insulating materials can help prevent this issue.

Citations:

[1] https://jhfoster.com/automation-blogs/six-reasons-to-consider-t-slot-aluminum-vs-steel/

[2] https://www.alineautomation.com/the-difference-between-steel-and-aluminum-extrusion/

[3] https://jieyatwinscrew.com/blog/80-20-aluminum-extrusion/

[4] https://www.youtube.com/watch?v=L2hWexf1xzM

[5] https://blog.knottsco.com/blog/bid/26913/Choosing-The-Correct-80-20-Aluminum-Extrusion-for-Your-Application

[6] https://www.gdcalm.com/some-questions-about-aluminum-extrusion.html

[7] https://www.cnczone.com/forums/mechanical-calculations-engineering-design/238564-cad-engineering.html

[8] https://exlabesa.com/uk/2023/05/19/is-extruded-aluminum-stronger-than-steel/

[9] https://www.youtube.com/watch?v=tocrhZRgYcY

[10] https://pennair.com/blog/2023/02/02/80-20-aluminum-extrusion-what-is-it/

[11] https://starext.com/news/aluminum-extrusion-finishing-fabrication-frequently-asked-questions-faq

[12] https://www.reddit.com/r/simracing/comments/s4tnh8/aluminum_profile_comparison_simlab_to_industrial/

[13] https://anglelock.com/blog/how-much-weight-can-aluminum-extrusion-hold/