Content Menu

● Introduction to Dual Gear MK8 Extruders

>> Key Features of Dual Gear MK8 Extruders

● Benefits of Upgrading to a Dual Gear MK8 Extruder

● Installation and Calibration

● Advanced Features and Considerations

>> Dual Gear vs. Single Gear Extruders

>> Comparison with Other Extruder Types

>> Maintenance Tips

>> Common Issues and Solutions

>> Upgrading to Direct Drive

● Conclusion

● FAQ

>> 1. What are the main benefits of using a dual gear MK8 extruder?

>> 2. How do I install a dual gear MK8 extruder?

>> 3. Do I need to adjust E-steps after installing a dual gear MK8 extruder?

>> 4. What maintenance is required for a dual gear MK8 extruder?

>> 5. Is a dual gear MK8 extruder compatible with all 3D printers?

● Citations:

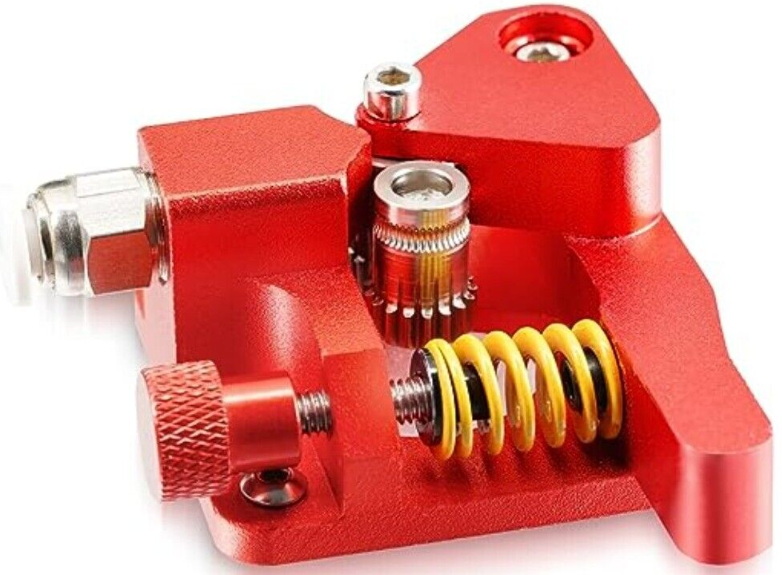

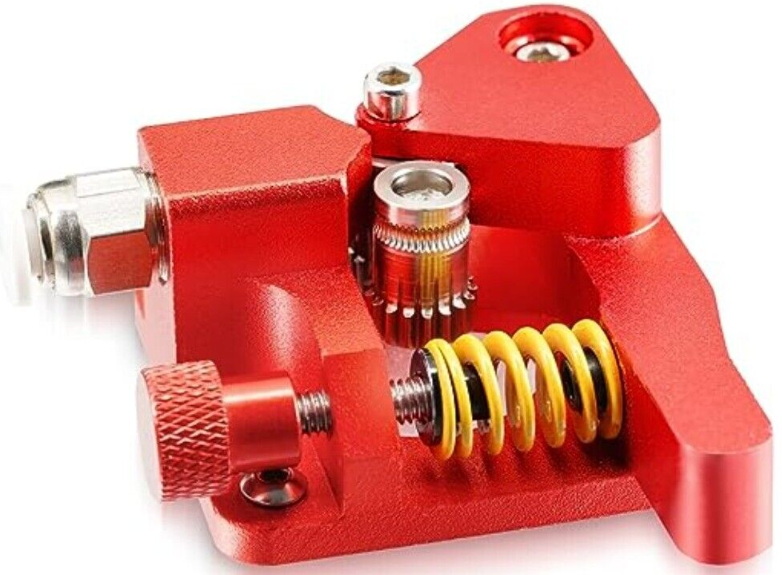

The dual gear MK8 extruder is a significant upgrade for 3D printers, offering enhanced performance and reliability compared to traditional plastic extruders. This article will delve into the benefits of using an aluminum upgrade dual gear MK8 extruder for extruder improvements, including better filament handling, increased durability, and improved print quality.

Introduction to Dual Gear MK8 Extruders

Dual gear extruders are designed to provide a more consistent and reliable filament feeding mechanism. Unlike single gear extruders, which can sometimes struggle with maintaining a steady grip on the filament, dual gear systems ensure that the filament is securely grasped from both sides. This design reduces slippage and grinding issues, which are common problems with plastic extruders.

Key Features of Dual Gear MK8 Extruders

- Dual Gear Mechanism: Provides a stronger grip on the filament, reducing slippage and grinding.

- Aluminum Construction: Offers durability and resistance to wear, unlike plastic extruders that can degrade quickly.

- Compatibility: Suitable for various 3D printer models, including Creality Ender 3 and CR-10 series.

- Easy Installation: Most kits come with all necessary components and are relatively straightforward to install.

Benefits of Upgrading to a Dual Gear MK8 Extruder

Upgrading to a dual gear MK8 extruder offers several advantages over stock plastic extruders:

1. Improved Filament Handling: The dual gear mechanism ensures a consistent and reliable grip on the filament, reducing issues like slippage and grinding. This is particularly beneficial for printing with flexible filaments or at high speeds.

2. Increased Durability: Aluminum extruders are more durable and resistant to wear compared to plastic ones. They can withstand the rigors of frequent use without degrading, making them a cost-effective option in the long run.

3. Enhanced Print Quality: By providing a consistent extrusion pressure, dual gear extruders help achieve smoother layers and better layer adhesion. This results in prints with fewer defects and improved overall quality.

4. Simplified Maintenance: Aluminum extruders require minimal maintenance. They are less prone to clogging and can be easily cleaned and lubricated as needed.

Installation and Calibration

Installing a dual gear MK8 extruder is relatively straightforward. Here are the general steps:

1. Remove the Old Extruder: Disconnect the motor and any wiring from the existing extruder.

2. Assemble the New Extruder: If the kit requires assembly, follow the provided instructions to ensure all parts are securely attached.

3. Mount the Extruder: Align the new extruder with the mounting holes on your printer and secure it using the screws provided.

4. Calibrate Your Printer: Adjust the extrusion settings in your slicer software to match the new setup. This may involve recalibrating the E-steps.

Advanced Features and Considerations

Dual Gear vs. Single Gear Extruders

Dual gear extruders offer superior performance compared to single gear extruders. The dual gear mechanism provides a tighter grip on the filament, reducing slippage and grinding. This is particularly beneficial for printing with flexible filaments or at high speeds.

Comparison with Other Extruder Types

- BMG Extruders: Known for their high-quality filament flow and grip, BMG extruders are popular for direct drive setups. However, they may require additional mounts and can be more expensive[6].

- Hemera Extruders: These extruders feature dual drive gears and offer high extrusion forces, making them suitable for demanding prints. They are more expensive but provide consistent performance[4].

Maintenance Tips

Regular maintenance is essential to ensure optimal performance from your dual gear MK8 extruder:

1. Clean the Gears: Regularly clean the extruder gears to prevent filament shavings from accumulating and affecting performance[5].

2. Adjust Tension: Ensure the extruder tension is properly set to avoid grinding or skipping issues[8].

3. Check Filament Path: Verify that the filament path is clear and not obstructed to prevent extrusion problems[8].

Common Issues and Solutions

- Skipping Steps: This can be due to clogged hotends or incorrect tension settings. Try cleaning the hotend and adjusting the tension[3].

- Filament Grinding: Check for worn-out gears or incorrect tension. Replace gears if necessary and adjust tension[3].

Upgrading to Direct Drive

For those interested in further improving print quality, upgrading to a direct drive setup can be beneficial. Direct drive extruders like the OMG DM1 offer lightweight and powerful performance, ideal for Ender-3 models[7].

Conclusion

Upgrading to an aluminum upgrade dual gear MK8 extruder for extruder can significantly enhance your 3D printing experience. With improved filament handling, increased durability, and better print quality, these extruders are a worthwhile investment for both hobbyists and professionals. Whether you're printing with PLA, PETG, or flexible filaments, a dual gear MK8 extruder ensures consistent and reliable performance.

FAQ

1. What are the main benefits of using a dual gear MK8 extruder?

The main benefits include improved filament handling, increased durability, and enhanced print quality. The dual gear mechanism reduces slippage and grinding, making it ideal for printing with various types of filaments.

2. How do I install a dual gear MK8 extruder?

Installation involves removing the old extruder, assembling the new one if necessary, mounting it on your printer, and calibrating your printer settings. Ensure all screws and components are securely attached.

3. Do I need to adjust E-steps after installing a dual gear MK8 extruder?

Yes, adjusting E-steps is necessary to ensure accurate extrusion. This involves recalibrating your printer's extrusion settings to match the new setup.

4. What maintenance is required for a dual gear MK8 extruder?

Regular cleaning and lubrication of moving parts are recommended. This helps maintain smooth operation and prevents wear.

5. Is a dual gear MK8 extruder compatible with all 3D printers?

Not all 3D printers are compatible with dual gear MK8 extruders. Ensure the extruder is compatible with your printer model before purchasing.

Citations:

[1] https://www.youtube.com/watch?v=QnrH2Sk7y40

[2] https://novo3d.in/dual-gear-extruder/

[3] https://www.reddit.com/r/ender3/comments/whyttn/issues_with_newly_installed_dual_gear_extrusion/

[4] https://www.cnckitchen.com/blog/which-is-the-strongest-3d-printing-extruder

[5] https://wiki.snapmaker.com/snapmaker_artisan/maintenance/clean_the_extruder_gears

[6] https://www.reddit.com/r/ender5/comments/jnanb6/mk8_extruder_on_e5pro_vs_dual_gear_extruder/

[7] https://www.youtube.com/watch?v=wx0FEp3uB2I

[8] https://www.cnckitchen.com/blog/how-to-set-extruder-tension

[9] https://www.youtube.com/watch?v=z2X4dc7jg4E

[10] https://www.aliexpress.com/item/1005004060542684.html

[11] https://www.mmobiel.com/mk8-extruder-drive-feed-dual-gear-upgraded-replacement-kit-for-1.75-filament-12v

[12] https://3dprintinguk.com/review-redrex-dual-gear-extruder/

[13] https://www.youtube.com/watch?v=qoj6PE7bkfc

[14] https://reprap.org/wiki/Dual_drive_geared_extruder

[15] https://tronic.lk/product/red-mk8-dual-gear-double-pulley-aluminum-extruder-right

[16] https://www.aliexpress.com/i/4000103526893.html

[17] https://www.aliexpress.com/i/1005005772942098.html

[18] https://www.youtube.com/watch?v=fT91Oj2RUDk

[19] https://www.crealityexperts.com/creality-extruder-guide

[20] https://www.aliexpress.com/item/4000103526893.html