Content Menu

● Introduction to Flexible Filaments

>> Challenges with Flexible Filaments

● Features of the Creality Gray Aluminum MK8 Bowden Extruder

>> Key Features:

● Handling Flexible Filaments

>> Tips for Printing Flexible Filaments:

● Comparison with Direct Drive Extruders

>> Advantages of Direct Drive Extruders:

● Optimizing the Creality Gray Aluminum MK8 Bowden Extruder for Flexible Filaments

● Compatibility with Various 3D Printers

● Maintenance and Upgrades

● Real-World Applications

● Conclusion

● FAQ

>> 1. Can the Creality Gray Aluminum MK8 Bowden Extruder handle flexible filaments?

>> 2. What are the recommended print settings for flexible filaments?

>> 3. How does the Creality Gray Aluminum MK8 Bowden Extruder compare to direct drive extruders for flexible filaments?

>> 4. What are the key features of the Creality Gray Aluminum MK8 Bowden Extruder?

>> 5. Is the Creality Gray Aluminum MK8 Bowden Extruder easy to install?

● Citations:

The Creality Gray Aluminum MK8 Bowden Extruder is a popular upgrade for various 3D printers, including models from Creality and other brands. This extruder is designed to enhance the printing experience by providing a more stable and durable setup compared to the stock plastic extruders. One of the key questions users have is whether this extruder can handle flexible filaments effectively. In this article, we will explore the capabilities of the Creality Gray Aluminum MK8 Bowden Extruder, focusing on its compatibility with flexible filaments like TPU and TPE.

Introduction to Flexible Filaments

Flexible filaments, such as TPU (Thermoplastic Polyurethane) and TPE (Thermoplastic Elastomer), present unique challenges in 3D printing. They are more prone to bending and twisting, which can cause issues with the extruder's ability to feed them consistently. These filaments require careful handling due to their tendency to buckle or escape from the extruder.

Challenges with Flexible Filaments

1. Buckling and Escaping: Flexible filaments can buckle or escape from the extruder due to their elasticity and the longer filament path in Bowden setups.

2. Slippage and Grinding: The extruder's drive gears must grip the filament firmly to prevent slippage or grinding, which can lead to print failures.

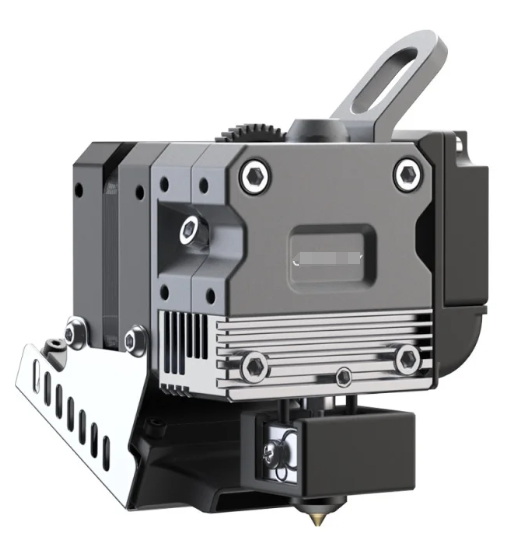

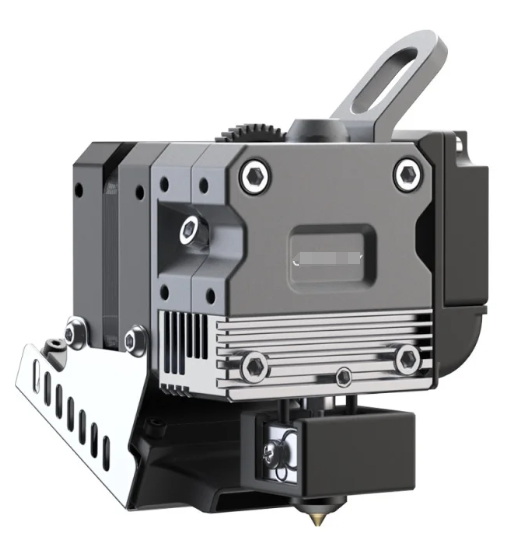

Features of the Creality Gray Aluminum MK8 Bowden Extruder

The Creality Gray Aluminum MK8 Bowden Extruder is constructed from high-quality aluminum, ensuring durability and stability. It is designed for 1.75mm filaments and is widely compatible with various 3D printer models, including the Ender 3, Ender 5, and CR-10 series.

Key Features:

- Material: High-quality aluminum for enhanced durability.

- Compatibility: Designed for 1.75mm filaments, suitable for PLA, ABS, PETG, and flexible materials.

- Easy Installation: Comes with instructions for straightforward installation.

- Drive Gear System: Equipped with a robust drive gear system to grip the filament firmly.

Handling Flexible Filaments

While the Creality Gray Aluminum MK8 Bowden Extruder is not specifically designed for flexible filaments, it can handle them with proper optimization. Here are some tips for printing with flexible filaments:

Tips for Printing Flexible Filaments:

1. Optimize Print Settings:

- Print Speed: Slow down the print speed to prevent buckling and ensure better layer adhesion. A speed of 20-40 mm/s is generally recommended.

- Temperature: Flexible filaments typically require higher printing temperatures. Refer to the filament manufacturer's recommendations.

- Retraction: Adjust retraction settings to minimize stringing and oozing. Lower retraction distances and speeds are recommended.

2. Use High-Quality Filaments: Experiment with different brands and types of flexible filaments to find those that work best with your setup.

3. Closed Travel Path: Ensure that the filament path is closed from the extruder gear to the hotend to prevent kinking.

Comparison with Direct Drive Extruders

Direct drive extruders are often preferred for flexible filaments due to their shorter filament path and reduced risk of clogs. However, a well-optimized Bowden setup with good quality PTFE tubing and precise temperature control can also work effectively.

Advantages of Direct Drive Extruders:

- Constrained Filament Path: Reduces the likelihood of filament buckling or escaping.

- Better Retraction Control: Offers superior control over retraction, which is beneficial for handling flexible filaments.

Optimizing the Creality Gray Aluminum MK8 Bowden Extruder for Flexible Filaments

To improve the performance of the Creality Gray Aluminum MK8 Bowden Extruder with flexible filaments, consider the following optimizations:

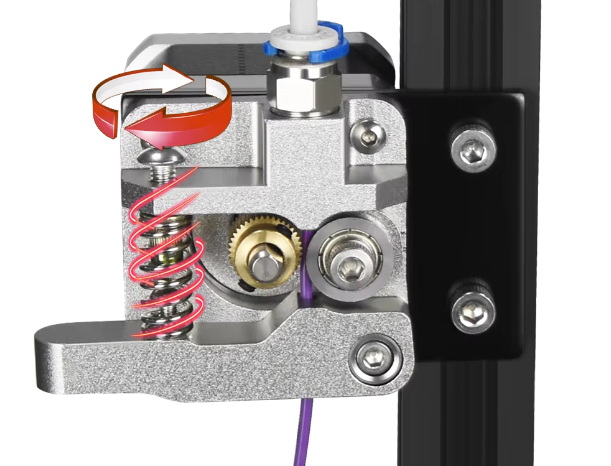

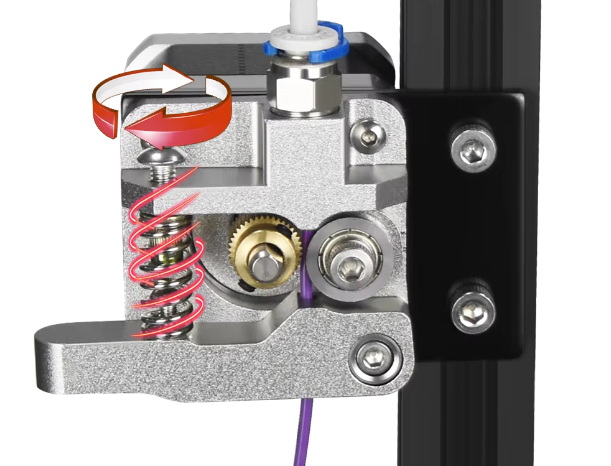

1. Tighter Tolerance Bowden Tubes: Using tubes with a smaller inner diameter, such as Capricorn or TH3D Tough Tube, can reduce buckling and improve filament feeding[1].

2. Enhanced Drive Gear System: Upgrading to dual gear or high-quality drive gears can provide better grip on the filament, reducing slippage[4].

3. Filament Guide Modifications: Adding a short piece of Bowden tube into the extruder housing can prevent filament flexing and improve feeding[1].

Compatibility with Various 3D Printers

The Creality Gray Aluminum MK8 Bowden Extruder is compatible with a wide range of 3D printers, including the Ender series and CR-10 series. It does not require changing stepper motors or other mounting hardware, making it a convenient upgrade for many users[2][5].

Maintenance and Upgrades

To ensure optimal performance, regular maintenance is crucial. This includes cleaning the extruder gears and checking for wear on the drive system. Upgrading to better quality drive gears or using specialized Bowden tubes can further enhance performance with flexible filaments[4].

Real-World Applications

Flexible filaments are used in various applications, such as creating flexible parts for robotics, wearable devices, and custom phone cases. With the right setup and optimizations, the Creality Gray Aluminum MK8 Bowden Extruder can effectively handle these filaments, providing a reliable and cost-effective solution for hobbyists and professionals alike.

Conclusion

The Creality Gray Aluminum MK8 Bowden Extruder can handle flexible filaments with proper optimization and setup adjustments. While it may not be the best choice for flexible filaments compared to direct drive extruders, it offers significant improvements in durability and print quality over stock plastic extruders.

FAQ

1. Can the Creality Gray Aluminum MK8 Bowden Extruder handle flexible filaments?

Yes, it can handle flexible filaments with proper optimization and adjustments to print settings.

2. What are the recommended print settings for flexible filaments?

- Print Speed: 20-40 mm/s.

- Temperature: Follow the filament manufacturer's recommendations.

- Retraction: Lower retraction distances and speeds.

3. How does the Creality Gray Aluminum MK8 Bowden Extruder compare to direct drive extruders for flexible filaments?

Direct drive extruders are generally better for flexible filaments due to their shorter filament path and better retraction control. However, a well-optimized Bowden setup can also be effective.

4. What are the key features of the Creality Gray Aluminum MK8 Bowden Extruder?

- Material: High-quality aluminum.

- Compatibility: Designed for 1.75mm filaments.

- Drive Gear System: Robust drive gears for firm filament grip.

5. Is the Creality Gray Aluminum MK8 Bowden Extruder easy to install?

Yes, it comes with instructions for straightforward installation and does not require changing stepper motors or other mounting hardware.

Citations:

[1] https://www.reddit.com/r/CR10/comments/l98ril/settings_for_flexible_filament/

[2] https://www.indiamart.com/proddetail/upgrade-ender-3-extruder-kit-ender-3-v2-upgrades-metal-extruder-aluminum-mk8-bowden-extruder-40-teeth-drive-gear-for-ender-3-pro-ender-5-pro-ender-5-plus-cr-10-series-3d-printer-rs6177-2855236104662.html

[3] https://www.yjing-extrusion.com/is-the-aluminum-mk8-extruder-compatible-with-all-3d-printers.html

[4] https://macewen3d.com/products/mk8-extruder-aluminum-drive-feed-for-cr-10-cr-10-s4-and-cr-10-s5

[5] https://store.dremc.com.au/products/all-metal-mk8-bowden-extruder-drive-feed-frame

[6] https://www.youtube.com/watch?v=Npuocf_f0jk

[7] https://www.aliexpress.com/i/1005003137308082.html

[8] https://www.aliexpress.com/i/1005004444272828.html

[9] https://www.aliexpress.com/item/1005003137308082.html

[10] https://forum.creality.com/t/best-flexible-filament-to-use/16761

[11] https://www.newegg.com/p/2S7-07JP-1A1X3

[12] https://www.desertcart.ma/search/bowden-extruder

[13] https://www.aliexpress.com/i/32927939042.html

[14] https://www.youtube.com/watch?v=X2k8uJ9m4lw

[15] https://grobotronics.com/bowden-extruder-feed-kit-mk8-silver-1.75mm-aluminum.html?sl=en

[16] https://www.newegg.com/p/2S7-07JP-1A1U9