Content Menu

● Introduction to the Bulldog Aluminum Extruder

>> Key Features of the Bulldog Aluminum Extruder

● Enhancements in Print Quality

>> 1. Reduced Filament Slippage

>> 2. Improved Thermal Management

>> 3. Enhanced Structural Integrity

● Applications of the Bulldog Aluminum Extruder

>> 1. Rapid Prototyping

>> 2. Manufacturing

>> 3. Education and Research

● Technical Considerations

>> 1. Filament Compatibility

>> 2. Retraction Settings

>> 3. Printer Frame Stability

● Benefits of Geared Extruders

>> 1. Increased Resolution

>> 2. Enhanced Consistency

>> 3. Reduced Wear on Filaments

● Upgrading to a Geared Extruder

>> 1. Cost-Effectiveness

>> 2. Compatibility

>> 3. Calibration

● Aluminum Extrusions in 3D Printing

>> Advantages of Aluminum Extrusions

● Advanced Printing Techniques with the Bulldog Extruder

>> Multi-Material Printing

>> High-Temperature Filaments

>> 3D Printing in Aerospace and Automotive Industries

>> Customization and Innovation

● Troubleshooting Common Issues

>> Filament Slippage

>> Clogging

● Comparison with Other Extruders

>> BMG Extruder

>> Orbiter Extruder

● Future Developments in Extruder Technology

>> Impact on Industry

● Conclusion

● FAQ

>> 1. What are the primary benefits of using an aluminum extruder like the Bulldog?

>> 2. How does the Bulldog extruder handle flexible filaments?

>> 3. Can the Bulldog extruder be used in both direct and Bowden setups?

>> 4. What maintenance is required for the Bulldog extruder?

>> 5. How does the Bulldog extruder contribute to printer stability?

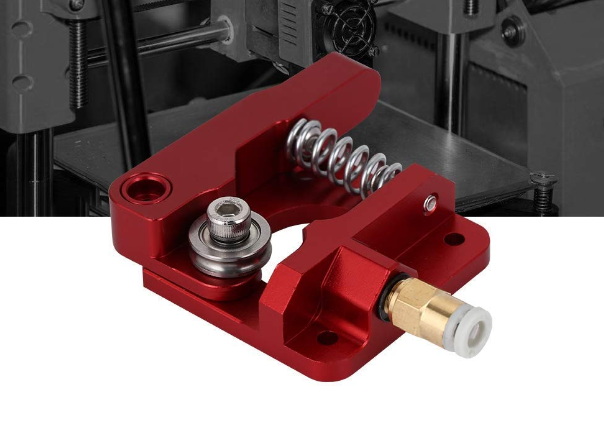

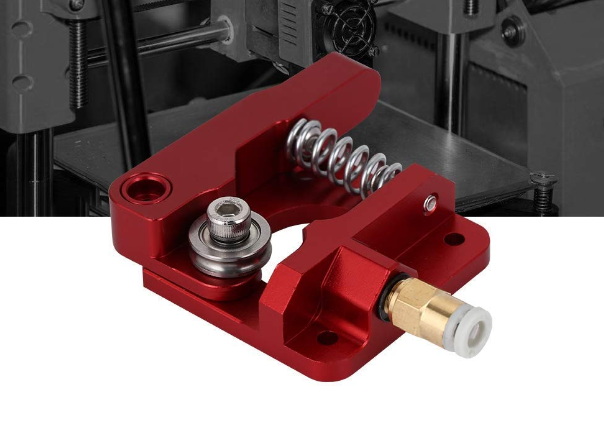

The Bulldog aluminum extruder is a highly regarded component in the 3D printing community, known for its robust design and ability to enhance print quality. This article will delve into the specifics of how the Bulldog extruder improves print quality, its features, and its applications in various printing scenarios.

Introduction to the Bulldog Aluminum Extruder

The Bulldog extruder is a full-metal extruder designed by RepRapDiscount, featuring a sturdy construction that supports both direct and Bowden printing setups. Its design includes a 5:1 geared system, which provides precise filament control, making it suitable for a wide range of filaments, including PLA, ABS, PETG, and more flexible materials like TPU and TPE.

Key Features of the Bulldog Aluminum Extruder

1. Geared System: The 5:1 gearing ratio allows for finer control over filament extrusion, enabling smoother and more consistent prints.

2. All-Metal Construction: The use of aluminum alloy ensures durability and resistance to wear, maintaining performance over time.

3. Versatile Compatibility: It can be used with various hotends, such as the E3D, J-Head, and MK8/MK10, making it adaptable to different printer configurations.

Enhancements in Print Quality

The Bulldog aluminum extruder contributes to improved print quality through several mechanisms:

1. Reduced Filament Slippage

The extruder's self-locking mechanism and deep-groove hobbed gear ensure a firm grip on the filament, minimizing slippage and ensuring consistent extrusion rates. This feature is particularly beneficial for maintaining layer adhesion and preventing defects like under-extrusion.

2. Improved Thermal Management

Although not directly related to thermal management, the aluminum construction of the extruder contributes to overall printer stability, which indirectly supports better thermal performance by reducing vibrations that could affect temperature control.

3. Enhanced Structural Integrity

The all-metal design provides a robust framework that resists mechanical stress, ensuring that the extruder remains stable during printing. This stability is crucial for maintaining precise filament feeding and retraction, which are essential for high-quality prints.

Applications of the Bulldog Aluminum Extruder

The Bulldog extruder is versatile and can be applied in various printing scenarios:

1. Rapid Prototyping

In product development, the Bulldog extruder's precision and reliability make it ideal for rapid prototyping, allowing designers to quickly iterate on designs and test new concepts.

2. Manufacturing

For manufacturing applications, the extruder's ability to handle a wide range of filaments and its durability under continuous use make it suitable for producing large quantities of parts.

3. Education and Research

In educational settings, the Bulldog extruder facilitates hands-on learning by providing students with a reliable tool for experimenting with different printing techniques and materials.

Technical Considerations

To maximize the benefits of the Bulldog aluminum extruder, several technical considerations must be addressed:

1. Filament Compatibility

While the Bulldog extruder supports a variety of filaments, flexible materials may require adjustments to ensure smooth feeding. Using a high-quality PTFE tube with a tight inner diameter can improve the feeding of flexible filaments.

2. Retraction Settings

For optimal performance, retraction settings should be carefully tuned to prevent oozing and stringing. This is particularly important when using the extruder in a Bowden setup.

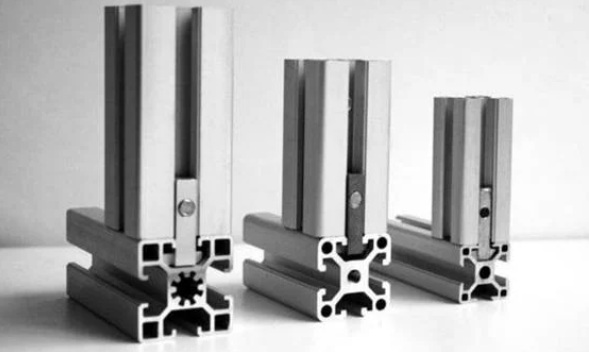

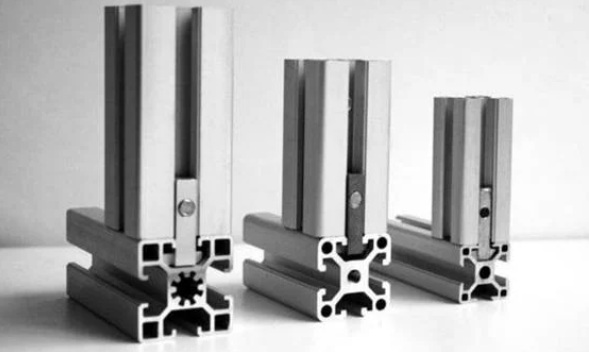

3. Printer Frame Stability

The overall stability of the printer frame is crucial for maintaining print quality. Aluminum extrusions are often used to construct frames due to their rigidity and ability to minimize vibrations.

Benefits of Geared Extruders

Geared extruders like the Bulldog offer several advantages over non-geared systems:

1. Increased Resolution

The gearing system provides higher resolution in filament movement, allowing for smoother extrusion and reduced ripple effects on prints. This is particularly beneficial for slower extrusion rates where precision is key.

2. Enhanced Consistency

By providing more precise control over filament flow, geared extruders ensure consistent layer thickness and quality, which is essential for achieving high-quality prints.

3. Reduced Wear on Filaments

The deep-groove hobbed gear in geared extruders minimizes the wear on filaments, reducing the risk of filament damage during extrusion.

Upgrading to a Geared Extruder

Upgrading to a geared extruder like the Bulldog can significantly enhance print quality. Here are some considerations for those planning an upgrade:

1. Cost-Effectiveness

While high-quality geared extruders can be more expensive, clones or DIY solutions can offer similar performance at a lower cost.

2. Compatibility

Ensure that the extruder is compatible with your printer's setup, including the hotend and firmware.

3. Calibration

After installing a new extruder, it's crucial to recalibrate the e-steps to ensure optimal performance.

Aluminum Extrusions in 3D Printing

Aluminum extrusions play a significant role in 3D printing beyond just extruders. They are commonly used in printer frames due to their strength, light weight, and corrosion resistance. These properties make aluminum ideal for constructing durable and efficient printers.

Advantages of Aluminum Extrusions

- Lightweight and Strong: Aluminum is about one-third the weight of steel, making it easier to handle and transport.

- Corrosion Resistance: Aluminum naturally forms a protective oxide layer, enhancing its durability in various environments.

- Thermal Conductivity: Aluminum is an excellent conductor of heat, which can be beneficial for managing thermal dynamics in printers.

Advanced Printing Techniques with the Bulldog Extruder

Multi-Material Printing

The Bulldog extruder's versatility allows it to be used in multi-material printing setups. By integrating multiple extruders, users can create complex prints with different materials, enhancing the aesthetic and functional capabilities of their prints.

High-Temperature Filaments

For printing high-temperature filaments like PEEK, modifications to the extruder and hotend may be necessary to achieve optimal results. The Bulldog extruder's robust design makes it a suitable base for such modifications.

3D Printing in Aerospace and Automotive Industries

In industries like aerospace and automotive, precision and reliability are paramount. The Bulldog extruder's ability to handle a variety of materials and maintain consistent print quality makes it suitable for producing parts that meet stringent industry standards.

Customization and Innovation

The Bulldog extruder's compatibility with various printer configurations allows users to experiment with custom designs and innovative printing techniques. This flexibility fosters creativity and innovation in 3D printing applications.

Troubleshooting Common Issues

Filament Slippage

If filament slippage occurs, check the tension on the extruder's gear and ensure that the filament is properly seated in the hobbed gear.

Clogging

Regular cleaning of the extruder and Bowden tube can prevent clogs. Use compressed air or a cleaning filament to clear any blockages.

Comparison with Other Extruders

BMG Extruder

The BMG extruder is known for its dual-gear design, which provides excellent filament grip and control. While more expensive, it offers superior performance for demanding printing tasks.

Orbiter Extruder

The Orbiter extruder features an all-printed design, making it highly customizable and reliable. It is a cost-effective option for those who prefer DIY solutions.

Future Developments in Extruder Technology

As 3D printing technology advances, extruders are evolving to meet new demands. Future developments may include more efficient gearing systems, improved thermal management, and enhanced compatibility with emerging materials.

Impact on Industry

Advancements in extruder technology will continue to drive innovation in industries reliant on 3D printing, such as healthcare, aerospace, and automotive. Improved print quality and efficiency will enable the production of more complex and precise parts.

Conclusion

The Bulldog aluminum extruder is a valuable component for enhancing print quality in 3D printing. Its robust design, precision gearing, and versatility make it suitable for a wide range of applications, from rapid prototyping to manufacturing and educational settings. By understanding its features and technical considerations, users can optimize their printing setups to achieve high-quality prints consistently.

FAQ

1. What are the primary benefits of using an aluminum extruder like the Bulldog?

The primary benefits include durability, precision filament control, and reduced filament slippage, which contribute to improved print quality and consistency.

2. How does the Bulldog extruder handle flexible filaments?

The Bulldog extruder can handle flexible filaments like TPU and TPE, but may require adjustments such as using a high-quality PTFE tube to minimize buckling and improve feeding.

3. Can the Bulldog extruder be used in both direct and Bowden setups?

Yes, the Bulldog extruder is designed to be compatible with both direct and Bowden printing configurations, offering flexibility in setup choices.

4. What maintenance is required for the Bulldog extruder?

Regular maintenance involves inspecting and cleaning the extruder and Bowden tube (if used) to prevent clogging and ensure smooth filament feeding.

5. How does the Bulldog extruder contribute to printer stability?

The all-metal construction of the Bulldog extruder provides structural integrity, which contributes to overall printer stability by resisting mechanical stress and vibrations.