Content Menu

● Introduction

● Understanding the Anodizing Process

>> Types of Anodizing Techniques

● Key Benefits of Anodized Aluminum Extrusions

>> Enhanced Durability and Corrosion Resistance

>> Aesthetic Appeal and Color Options

>> Improved Surface Hardness and Wear Resistance

● Applications of Anodized Aluminum Extrusions

>> Use in Construction and Architecture

>> Applications in Automotive and Aerospace Industries

>> Role in Consumer Products and Electronics

● Choosing the Right Anodized Aluminum Supplier

>> Quality

>> Lead Time

>> Customization Options

>> Importance of Certifications and Standards

>> Tips for Evaluating Potential Suppliers

● Conclusion

● Related Questions

>> 1. What is the difference between anodized and untreated aluminum?

>> 2. How does anodizing affect the weight of aluminum extrusions?

>> 3. Can anodized aluminum be recycled?

>> 4. What industries commonly use anodized aluminum extrusions?

>> 5. How can I maintain the appearance of anodized aluminum?

Introduction

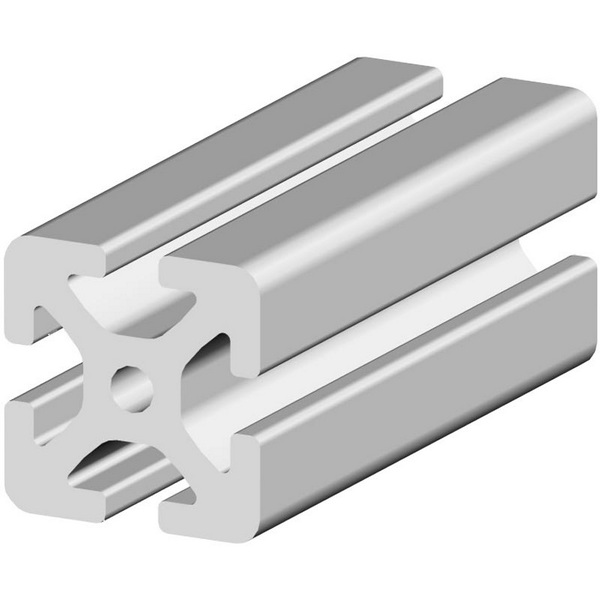

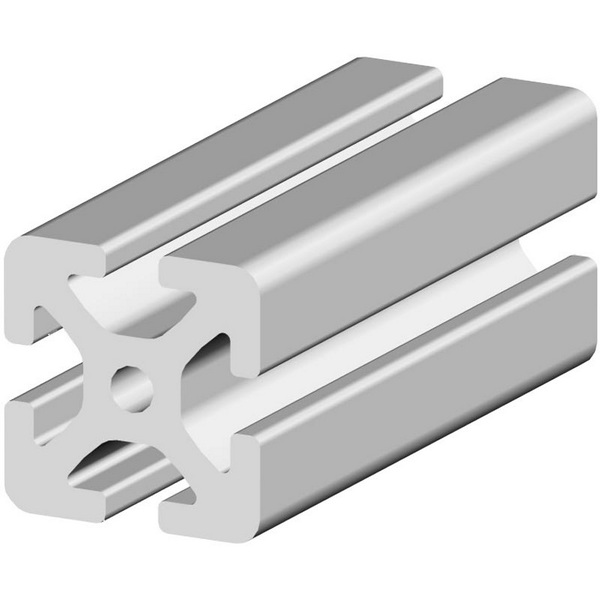

Aluminum extrusion is a manufacturing process that shapes aluminum alloy into a desired cross-sectional profile. This technique is widely used in various industries due to its versatility and efficiency. One of the most significant advantages of aluminum extrusion is its ability to enhance product durability, particularly when combined with anodizing. Anodized aluminum extrusion not only improves the physical properties of aluminum but also extends its lifespan, making it a preferred choice for many applications. In this article, we will explore how the aluminum extrusion process enhances product durability, the benefits of anodizing, and the various applications of anodized aluminum extrusions.

Understanding the Anodizing Process

Anodizing is an electrochemical process that converts the metal surface into a decorative, durable, corrosion-resistant, anodic oxide finish. The process involves immersing the aluminum in an acid electrolyte bath and passing an electric current through the medium. This results in the formation of a thick oxide layer on the surface of the aluminum, which significantly enhances its durability.

Types of Anodizing Techniques

There are several types of anodizing techniques, each offering different benefits:

- Type I Anodizing: This method uses chromic acid and is primarily used for applications requiring corrosion resistance and minimal dimensional change.

- Type II Anodizing: This is the most common anodizing process, using sulfuric acid to create a thicker oxide layer, which provides excellent corrosion resistance and wear resistance.

- Type III Anodizing: Also known as hard anodizing, this technique produces a thicker and harder oxide layer, making it suitable for high-wear applications.

Key Benefits of Anodized Aluminum Extrusions

Anodized aluminum extrusions offer numerous benefits that contribute to their durability:

Enhanced Durability and Corrosion Resistance

The anodizing process creates a protective layer on the aluminum surface, which is significantly more durable than untreated aluminum. This layer protects against corrosion, wear, and environmental damage, making anodized aluminum extrusions ideal for outdoor applications and harsh environments.

Aesthetic Appeal and Color Options

Anodized aluminum can be dyed in various colors, allowing for aesthetic customization without compromising durability. This feature is particularly beneficial in architectural applications where appearance is as important as functionality.

Improved Surface Hardness and Wear Resistance

The anodized layer increases the surface hardness of aluminum, making it more resistant to scratches and abrasions. This property is crucial for products that undergo frequent handling or are exposed to abrasive conditions.

Applications of Anodized Aluminum Extrusions

Anodized aluminum extrusions are used in a wide range of industries due to their enhanced durability and versatility:

Use in Construction and Architecture

In the construction industry, anodized aluminum extrusions are commonly used for window frames, curtain walls, and roofing systems. Their resistance to corrosion and weathering makes them an excellent choice for exterior applications.

Applications in Automotive and Aerospace Industries

The automotive and aerospace industries benefit from anodized aluminum extrusions due to their lightweight and durable nature. Components such as structural frames, brackets, and heat exchangers are often made from anodized aluminum to improve performance and longevity.

Role in Consumer Products and Electronics

Anodized aluminum is also prevalent in consumer products, including appliances, furniture, and electronic devices. The durability of anodized aluminum ensures that these products can withstand daily use while maintaining their appearance.

Choosing the Right Anodized Aluminum Supplier

When selecting a supplier for anodized aluminum extrusions, several factors should be considered:

Quality

Ensure that the supplier adheres to industry standards and provides high-quality anodized aluminum products. Look for certifications that demonstrate their commitment to quality.

Lead Time

Consider the supplier's lead time for production and delivery. A reliable supplier should be able to meet your project deadlines without compromising quality.

Customization Options

Many projects require specific dimensions and finishes. Choose a supplier that offers customization options to meet your unique needs.

Importance of Certifications and Standards

Verify that the supplier complies with relevant industry standards, such as ISO certifications, to ensure the quality and reliability of their products.

Tips for Evaluating Potential Suppliers

Request samples of their anodized aluminum extrusions to assess quality firsthand. Additionally, read customer reviews and testimonials to gauge their reputation in the industry.

Conclusion

The aluminum extrusion process, combined with anodizing, significantly enhances product durability. Anodized aluminum extrusions offer superior corrosion resistance, aesthetic appeal, and improved surface hardness, making them suitable for a wide range of applications. By understanding the benefits of anodized aluminum and choosing the right supplier, manufacturers can ensure the longevity and performance of their products.

Related Questions

1. What is the difference between anodized and untreated aluminum?

Anodized aluminum has a protective oxide layer that enhances its durability and corrosion resistance, while untreated aluminum is more susceptible to corrosion and wear.

2. How does anodizing affect the weight of aluminum extrusions?

Anodizing does not significantly affect the weight of aluminum extrusions, as the process adds a thin layer to the surface without altering the overall mass.

3. Can anodized aluminum be recycled?

Yes, anodized aluminum is fully recyclable, and the anodizing process does not hinder its recyclability.

4. What industries commonly use anodized aluminum extrusions?

Anodized aluminum extrusions are widely used in construction, automotive, aerospace, and consumer products industries.

5. How can I maintain the appearance of anodized aluminum?

To maintain the appearance of anodized aluminum, clean it regularly with mild soap and water, and avoid using abrasive cleaners that can damage the anodized layer.