Content Menu

● Introduction to Plastic Water Pipe Extrusion Machinery

● The Fundamentals of Pipe Extrusion

● Key Components of Plastic Water Pipe Extrusion Machinery

● How Extrusion Machinery Reduces Production Costs

>> 1. Energy Efficiency

>> 2. Material Optimization

>> 3. Labor Savings

>> 4. Enhanced Production Speed

>> 5. Reduced Waste and Scrap

● Technological Advancements in Plastic Water Pipe Extrusion

● Quality Control and Consistency

● Environmental Impact and Sustainability

● Case Studies: Real-World Cost Savings

>> Case Study 1: Medium-Sized Pipe Manufacturer

>> Case Study 2: Large-Scale Exporter

● Conclusion

● FAQ: Frequently Asked Questions

>> 1. What are the main types of plastic water pipe extrusion machinery?

>> 2. How does automation in extrusion machinery reduce labor costs?

>> 3. Can extrusion machinery handle recycled plastic materials?

>> 4. What maintenance is required for plastic water pipe extrusion machinery?

>> 5. How does extrusion machinery contribute to environmental sustainability?

In today's competitive manufacturing environment, companies are constantly seeking ways to enhance efficiency, improve product quality, and reduce operational costs. One of the most transformative innovations in the production of plastic water pipes is the advent of advanced plastic water pipe extrusion machinery. This technology has revolutionized the industry, enabling manufacturers to produce high-quality pipes at a fraction of the previous cost. In this comprehensive article, we will delve into how plastic water pipe extrusion machinery helps reduce production costs, the key features and benefits of these systems, and why they are essential for any modern pipe manufacturing operation.

Introduction to Plastic Water Pipe Extrusion Machinery

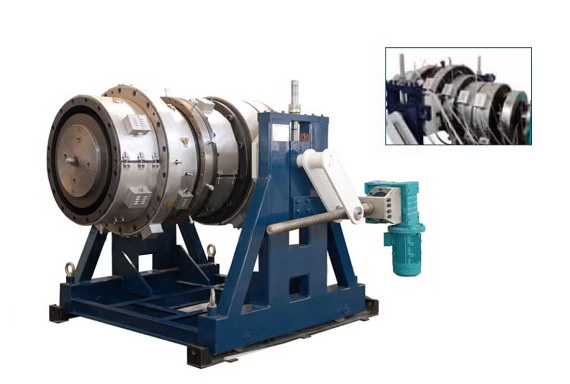

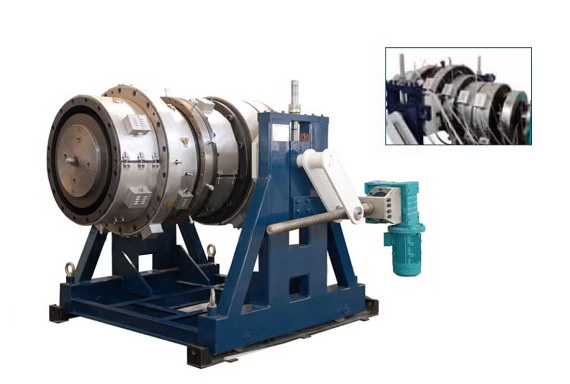

Plastic water pipe extrusion machinery refers to specialized industrial equipment designed to manufacture plastic pipes through a continuous extrusion process. This machinery is central to the production of pipes used in plumbing, irrigation, and various water supply systems. The process involves melting plastic raw materials—such as PVC, HDPE, or PPR—and shaping them into pipes of various diameters and thicknesses.

The significance of plastic water pipe extrusion machinery lies in its ability to produce pipes with precise specifications, high durability, and at a much lower cost compared to traditional manufacturing methods. As the demand for plastic pipes continues to grow globally, the role of efficient extrusion machinery becomes increasingly critical.

The Fundamentals of Pipe Extrusion

Pipe extrusion is a continuous manufacturing process where plastic raw materials are melted and forced through a die to create long, uniform pipes. The process typically involves the following steps:

1. Feeding: Plastic pellets or powder are fed into the extruder's hopper.

2. Melting: The material is heated and melted as it moves through the extruder barrel.

3. Extrusion: The molten plastic is pushed through a die, forming the pipe's shape.

4. Cooling: The pipe is cooled, usually in a water bath, to solidify its structure.

5. Cutting: The continuous pipe is cut into desired lengths.

This process is highly efficient and can be tailored to produce pipes of various sizes, wall thicknesses, and material compositions.

Key Components of Plastic Water Pipe Extrusion Machinery

To understand how plastic water pipe extrusion machinery reduces production costs, it is essential to know its main components:

- Extruder: The heart of the system, responsible for melting and conveying the plastic material.

- Die Head: Shapes the molten plastic into a pipe.

- Vacuum Calibration Tank: Ensures the pipe maintains its shape and dimensions during cooling.

- Cooling System: Rapidly cools the extruded pipe, increasing production speed.

- Haul-Off Unit: Pulls the pipe through the line at a consistent speed.

- Cutter: Cuts the pipe to the required length.

- Control System: Automates and monitors the entire process for precision and efficiency.

Modern plastic water pipe extrusion machinery integrates these components with advanced automation and monitoring technologies, further enhancing productivity and cost savings.

How Extrusion Machinery Reduces Production Costs

The adoption of plastic water pipe extrusion machinery brings a multitude of cost-saving benefits to manufacturers. Let's explore the primary ways these systems help reduce production expenses:

1. Energy Efficiency

One of the most significant contributors to manufacturing costs is energy consumption. Advanced plastic water pipe extrusion machinery is designed with energy-efficient motors, heaters, and cooling systems. These innovations ensure that less electricity is used during the melting and extrusion process, directly lowering utility bills.

Modern extruders often feature variable frequency drives (VFDs) and optimized barrel designs that minimize heat loss and maximize energy transfer. As a result, manufacturers can produce more pipes per kilowatt-hour, significantly reducing the cost per unit.

2. Material Optimization

Raw material costs are another major expense in pipe production. Plastic water pipe extrusion machinery utilizes precise dosing and feeding systems, ensuring that the exact amount of material is used for each pipe. This precision minimizes overuse and waste, allowing manufacturers to stretch their raw material supplies further.

In addition, advanced machinery can process recycled plastics and blends, further reducing material costs without sacrificing product quality. Sophisticated control systems monitor the composition and flow of materials in real-time, ensuring optimal usage and reducing the risk of expensive errors.

3. Labor Savings

Automation is a cornerstone of modern plastic water pipe extrusion machinery. Automated systems require fewer operators, reducing labor costs and minimizing human error. Tasks such as material feeding, temperature control, pipe sizing, and cutting are all managed by programmable logic controllers (PLCs) and human-machine interfaces (HMIs).

With less need for manual intervention, manufacturers can reallocate labor resources to other areas of the operation, increasing overall productivity and reducing payroll expenses.

4. Enhanced Production Speed

Time is money in manufacturing. Plastic water pipe extrusion machinery is engineered for high-speed operation, enabling continuous production with minimal downtime. Faster production cycles mean more pipes can be produced in less time, increasing output and revenue potential.

Features such as rapid cooling systems, efficient haul-off units, and automated cutters ensure that the production line operates at maximum efficiency. This speed not only reduces per-unit costs but also allows manufacturers to meet tight deadlines and respond quickly to market demand.

5. Reduced Waste and Scrap

Waste management is a critical aspect of cost control. Traditional pipe manufacturing methods often result in significant material waste due to inconsistent quality and frequent defects. In contrast, plastic water pipe extrusion machinery incorporates advanced quality control systems that detect and correct issues in real time.

Inline measurement devices monitor pipe diameter, wall thickness, and surface quality, ensuring that only pipes meeting strict standards proceed through the line. Defective products are identified and removed early, reducing the amount of scrap and rework required. This reduction in waste translates directly into lower production costs and higher profitability.

Technological Advancements in Plastic Water Pipe Extrusion

The evolution of plastic water pipe extrusion machinery has been driven by continuous technological innovation. Some of the latest advancements include:

- Smart Automation: Integration of IoT sensors and AI-driven analytics for predictive maintenance and process optimization.

- Modular Design: Flexible machinery that can be quickly reconfigured for different pipe sizes and materials.

- Energy Recovery Systems: Technologies that capture and reuse waste heat, further reducing energy consumption.

- Advanced Cooling Techniques: Improved cooling systems that enable even faster production speeds without compromising pipe quality.

- Remote Monitoring: The ability to monitor and control machinery from remote locations, increasing operational flexibility.

These innovations not only enhance the performance of extrusion machinery but also contribute to ongoing reductions in production costs.

Quality Control and Consistency

Consistent product quality is essential for maintaining customer satisfaction and reducing costs associated with returns and rework. Plastic water pipe extrusion machinery is equipped with sophisticated quality control systems that ensure every pipe meets stringent industry standards.

- Laser Measurement: Inline laser systems measure pipe dimensions with micron-level accuracy.

- Automatic Feedback Loops: Real-time adjustments are made to process parameters to maintain consistent output.

- Defect Detection: Cameras and sensors identify surface defects, ovality, and other issues before pipes leave the production line.

By ensuring high-quality, defect-free pipes, manufacturers can avoid costly recalls and maintain a strong reputation in the market.

Environmental Impact and Sustainability

Sustainability is an increasingly important consideration in manufacturing. Plastic water pipe extrusion machinery supports eco-friendly production in several ways:

- Reduced Energy Use: Energy-efficient machinery lowers the carbon footprint of pipe production.

- Recycled Materials: The ability to process recycled plastics reduces reliance on virgin materials and supports circular economy initiatives.

- Minimized Waste: Precision manufacturing and quality control systems reduce scrap, lowering the environmental impact of operations.

By adopting sustainable practices, manufacturers not only reduce costs but also appeal to environmentally conscious customers and comply with regulatory requirements.

Case Studies: Real-World Cost Savings

To illustrate the tangible benefits of plastic water pipe extrusion machinery, let's examine a few real-world examples:

Case Study 1: Medium-Sized Pipe Manufacturer

A medium-sized company upgraded its production line with state-of-the-art extrusion machinery. As a result, they achieved:

- 25% reduction in energy consumption

- 15% decrease in raw material usage due to improved dosing systems

- 30% increase in production speed

- 50% reduction in labor costs through automation

These improvements led to a significant reduction in overall production costs and a rapid return on investment.

Case Study 2: Large-Scale Exporter

A large exporter of plastic water pipes adopted advanced extrusion machinery featuring IoT-enabled monitoring and predictive maintenance. The company reported:

- 40% reduction in unplanned downtime

- 20% lower maintenance costs

- Enhanced product quality, leading to fewer customer complaints and returns

By leveraging cutting-edge technology, the company maintained a competitive edge in the global market while controlling costs.

Conclusion

Plastic water pipe extrusion machinery has fundamentally transformed the pipe manufacturing industry. By enhancing energy efficiency, optimizing material usage, reducing labor requirements, increasing production speed, and minimizing waste, these systems deliver substantial cost savings for manufacturers. Technological advancements continue to push the boundaries of what is possible, enabling even greater efficiency and sustainability.

For companies seeking to remain competitive in a rapidly evolving market, investing in modern plastic water pipe extrusion machinery is not just a smart financial decision—it is essential for long-term success. By embracing these innovations, manufacturers can produce high-quality pipes at lower costs, meet growing demand, and contribute to a more sustainable future.

FAQ: Frequently Asked Questions

1. What are the main types of plastic water pipe extrusion machinery?

There are several types of plastic water pipe extrusion machinery designed for different materials and pipe specifications. The most common include single-screw extruders (ideal for PVC and PE pipes), twin-screw extruders (used for complex formulations), and co-extrusion lines (for multi-layer pipes). Each type offers unique benefits in terms of efficiency, flexibility, and product quality.

2. How does automation in extrusion machinery reduce labor costs?

Automation in plastic water pipe extrusion machinery minimizes the need for manual intervention by automating tasks such as material feeding, temperature control, pipe sizing, and cutting. This reduces the number of operators required, lowers the risk of human error, and enables continuous, high-speed production, all of which contribute to lower labor costs.

3. Can extrusion machinery handle recycled plastic materials?

Yes, modern plastic water pipe extrusion machinery can process recycled plastics and blends. Advanced dosing and feeding systems ensure that recycled materials are incorporated without compromising product quality. This capability not only reduces raw material costs but also supports sustainable manufacturing practices.

4. What maintenance is required for plastic water pipe extrusion machinery?

Regular maintenance of plastic water pipe extrusion machinery includes cleaning the extruder barrel and die, checking and replacing worn parts, lubricating moving components, and calibrating control systems. Many modern machines feature predictive maintenance capabilities, using sensors to alert operators to potential issues before they cause downtime.

5. How does extrusion machinery contribute to environmental sustainability?

Plastic water pipe extrusion machinery supports environmental sustainability by reducing energy consumption, enabling the use of recycled materials, and minimizing production waste. Energy-efficient designs and advanced quality control systems ensure that resources are used responsibly, helping manufacturers meet environmental regulations and consumer expectations.