Content Menu

● The Growing Importance of Automatic Stackers

● Russian Market Overview: Demand and Trends

● Top Automatic Stacker Manufacturers And Suppliers in Russia

>> CORINMAC

>> New Technologies Group (Otto-Kurtbach)

>> Kalmar

>> Tauras-Fenix

>> Kardex

>> CLARK

>> Other Competitive Manufacturers and Suppliers

● Key Technical Features and Innovations

● Industry Applications and Use Cases

● Challenges and Opportunities in the Russian Market

● Conclusion

● Frequently Asked Questions (FAQ)

>> 1. What are the main benefits of using automatic stackers in Russian industries?

>> 2. Who are the top automatic stacker manufacturers and suppliers in Russia?

>> 3. How do automatic stackers handle Russia's extreme environments?

>> 4. What are typical applications of automatic stackers in aluminum extrusion plants?

>> 5. How can foreign buyers partner with Russian automatic stacker manufacturers and suppliers?

In today's highly competitive industrial landscape, automation is no longer a luxury but a necessity. Among the key solutions driving this transformation are automatic stackers, which have revolutionized material handling, storage, and logistics across multiple sectors. For businesses, especially those looking to streamline operations, reduce costs, and enhance efficiency, collaborating with reliable Automatic Stacker Manufacturers And Suppliers is critical.

Russia, with its vast geography, robust manufacturing environment, and growing logistics sector, represents a significant market for automatic stacker systems. This article explores the primary players in this field, analyzing features, innovations, and advantages provided by the top Automatic Stacker Manufacturers And Suppliers in Russia. Whether you are a global brand, wholesaler, or OEM seeking to optimize your warehouse or production processes, this comprehensive guide offers actionable insights and industry best practices.

The Growing Importance of Automatic Stackers

Automatic stackers are specialized automation devices used to handle, move, and organize products, parts, or pallets efficiently within warehouses, manufacturing plants, and distribution centers. They perform repetitive, physically demanding, and often dangerous stacking and material transportation tasks with high precision. As automation becomes widespread,

- Efficiency and Productivity: Automatic stackers dramatically increase throughput by working continuously with uniform speed and accuracy, thus optimizing material flow.

- Space Utilization: Stackers precisely arrange goods vertically and horizontally, maximizing use of existing space, which is crucial for high-density warehouses common in Russia.

- Labor & Safety Benefits: The adoption of automatic stackers significantly cuts down the need for manual labor, reduces the risk of workplace injuries, and ensures compliance with strict safety standards.

- Cost Reduction: By minimizing errors, downtime, labor costs, and product damage, stackers improve the overall ROI for industrial operations.

Russian Market Overview: Demand and Trends

The Russian industrial sector is expanding rapidly, with demand fueled by:

- Modernization of Warehouses: As retail, e-commerce, and logistics sectors soar, there is a surge in investment in modern automated warehousing.

- Industrial Diversity: Sectors including automotive, aluminum extrusion, food and beverage, heavy equipment, and electronics are heavily implementing stackers.

- Harsh Environments: Russian climatic conditions—extreme cold, humidity, and dust—necessitate robust and resilient stacking solutions.

- Technological Advancements: Russian and international manufacturers are racing to offer advanced features such as remote diagnostics, IoT integration, energy-efficient drives, and adaptive safety systems.

This landscape has fostered a highly competitive environment where Automatic Stacker Manufacturers And Suppliers continually innovate to meet industry requirements.

Top Automatic Stacker Manufacturers And Suppliers in Russia

CORINMAC

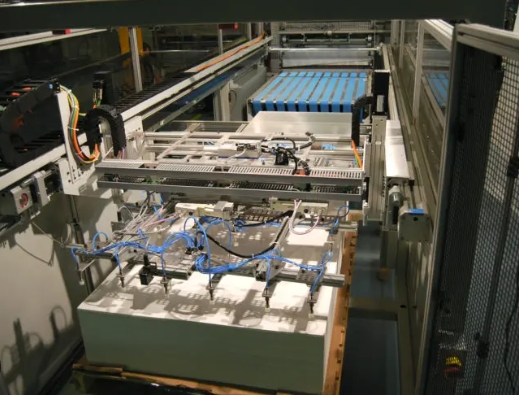

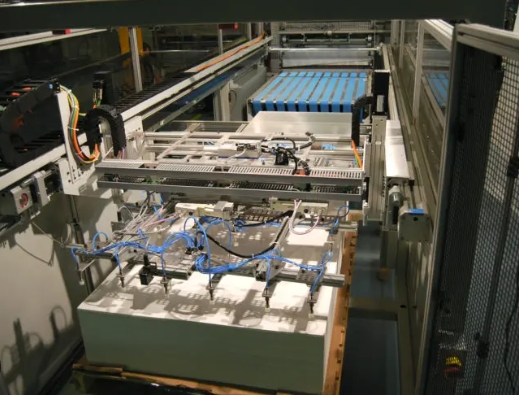

CORINMAC has established itself as a leader in automatic stacking and palletizing technology. Its systems are designed for resilience in the harsh industrial environments found across Russia.

Key Strengths:

- Rugged construction with corrosion and wear resistance.

- Integration of customizable robotic arms and conveyor systems tailored to specific production needs.

- Intelligent controls allow full automation, remote monitoring, and flexible data exchange with warehouse management software.

- Customized solutions for a vast range of industries, from heavy manufacturing to consumer goods packaging.

CORINMAC's commitment to innovation, reliability, and post-installation support has made it an attractive partner for OEMs and large-scale manufacturing operations.

New Technologies Group (Otto-Kurtbach)

With over a decade of experience, New Technologies Group, through its Otto-Kurtbach brand, supplies stackers built for the Russian market's toughest conditions.

Features and Benefits:

- A complete selection of hydraulic, electronic, and self-propelled stackers.

- Tailored for temperature extremes, high humidity, and abrasive environments.

- Strong after-sales service, technical support, and training for operators.

- Solutions for both small businesses and multinational factories.

Otto-Kurtbach is often chosen for handling diverse goods, from raw materials to finished products, in logistics hubs and manufacturing centers.

Kalmar

Kalmar's reputation in the heavy-duty, eco-efficient stacker market is well established, especially within Russian ports and steel production.

Highlighted Innovations:

- Electric-powered reach stackers with up to 45-ton capacity.

- Green steel and energy-efficient drives, supporting both sustainability and stringent regulatory environments.

- Advanced automation, diagnostics, and safety features for 24/7 operation.

- Modular designs that allow for quick adaptation to customer requirements.

Kalmar's robust engineering and sustainability focus appeal to Russian companies looking for long-term investment value.

Tauras-Fenix

Tauras-Fenix operates successfully within the packaging and end-of-line automation segments in Russia.

Advantages:

- Specializes in SPM-HAS 200 automatic loaders and stackers, designed for fast, accurate stacking during high-volume production cycles.

- Designed for easy integration with packing lines in food & beverage, pharmaceuticals, and light engineering sectors.

- Efficient layout and programming capability improve workflow and product quality.

- Expert remote support and optimization teams.

Tauras-Fenix is recognized for responsive customer service and the ability to deliver turnkey automation projects.

Kardex

Operating globally, Kardex has a solid presence in the Russian market, particularly through its state-of-the-art automated storage and retrieval solutions.

Product Features:

- Precision stacker cranes integrated with AS/RS for both pallets and small loads.

- Highly scalable and customizable warehouse automation.

- Complete integration with modern WMS (Warehouse Management Systems).

- Smart energy management and eco-friendly operations.

Kardex's stackers are a standout choice for high-value or space-constrained warehousing applications seeking optimal efficiency.

CLARK

CLARK offers a versatile range of stackers for Russian industry, focusing on ergonomic design, flexibility, and safety.

Why Choose CLARK?

- Load capabilities from 1 to 2 tonnes, with both pedestrian and ride-on models.

- Advanced lithium-ion battery systems for extended, maintenance-free operation in multi-shift environments.

- Automatic speed control, anti-rollback, and automatic power off for maximum operator safety.

- Reliable performance backed by transparent pricing and prompt local service.

CLARK's extensive product catalogue makes it suitable for a wide range of industrial and warehousing scenarios.

Other Competitive Manufacturers and Suppliers

Alongside these market leaders, several niche and specialized Automatic Stacker Manufacturers And Suppliers have found success by catering to unique client needs:

- Pratham Technologies serves export markets with robust vertical stacker systems, popular for reliability and ease of maintenance.

- Mobile Robot and AGV/AMR Suppliers: With increasing robotic automation, Russian facilities are deploying automated guided vehicles (AGVs) and autonomous mobile robots (AMRs) equipped with stacking capabilities—increasing throughput and flexibility.

- Local Startups and Engineering Firms: A healthy ecosystem of Russian engineering firms offer innovative solutions tailored to specific production lines, including hybrid stacker-conveyor systems and highly adaptive IoT-connected machines.

Key Technical Features and Innovations

In response to Russia's unique operational demands, leading Automatic Stacker Manufacturers And Suppliers deliver systems featuring:

- Extreme Durability: Corrosion-resistant steel, reinforced housing, and adaptive controls allow stackers to function in sub-zero temperatures and dusty conditions.

- Smart Controls and IoT Integration: Touchscreen HMIs, programmable logic controllers (PLCs), and cloud connectivity support predictive maintenance and remote troubleshooting.

- Energy Efficiency: Adoption of regenerative drives, lithium-ion batteries, and low-energy standby modes significantly reduce operational costs.

- Safety Automation: Enhanced collision detection, automatic load sensing, and emergency stop features ensure personnel and product safety even in busy, high-traffic environments.

- Customizability: Solutions can be tailored to handle everything from small cartons to oversized steel profiles or aluminum extrusions, integrating seamlessly into existing plant layouts.

Industry Applications and Use Cases

Automatic stackers are now essential components in numerous Russian industries:

- Warehousing and Distribution: Core to order fulfillment, cross-docking, and high-density storage.

- Automotive and Heavy Manufacturing: Handling engines, transmission components, metal coils, and large sub-assemblies.

- Aluminum Extrusion and Metallurgy: Transporting, stacking, and staging heavy profiles, billets, and finished products.

- Food and Beverage: Safely moving packaged goods, crates, and delicate items through sterile environments.

- Retail and E-commerce Fulfillment: Supporting rapid, accurate selection, movement, and shipping of orders.

With tailored solutions for specific workflows, Automatic Stacker Manufacturers And Suppliers help Russian companies meet local and global standards for quality, efficiency, and competitiveness.

Challenges and Opportunities in the Russian Market

Russia's large and diverse industrial base fosters both challenges and immense opportunities for stacker manufacturers and partners. While high initial investment and complex systems integration remain concerns for some, the long-term gains—in cost savings, efficiency, and flexibility—are undeniable.

Opportunities:

- Automation aligns with government incentives targeting modernization and productivity in manufacturing and logistics.

- Growing interest from international buyers seeking OEM partnerships with Russian suppliers offering high-quality engineering at competitive prices.

Challenges:

- Need for extensive operator training and ongoing technical support, often resolved through local partnership models.

- Compatibility with legacy systems, requiring modular stacker designs and seamless integration capabilities.

Conclusion

Russia's dynamic industrial environment has firmly cemented the role of innovation-driven, rugged, and value-focused Automatic Stacker Manufacturers And Suppliers. From established names like CORINMAC, Kalmar, and Kardex, to agile local engineering firms and robotics startups, the Russian market is rich with opportunity for end-users and international OEM partners.

Businesses interested in expanding their automation capabilities should closely evaluate each supplier's technological strengths, adaptability, track record, and commitment to sustained after-sales service. By doing so, they can ensure seamless integration, maximum ROI, and superior operational outcomes.

Frequently Asked Questions (FAQ)

1. What are the main benefits of using automatic stackers in Russian industries?

Automatic stacker systems enhance productivity, improve safety, reduce labor costs, and ensure consistent materials handling, making them vital for large-scale and challenging environments.

2. Who are the top automatic stacker manufacturers and suppliers in Russia?

Prominent players include CORINMAC, New Technologies Group (Otto-Kurtbach), Kalmar, Tauras-Fenix, Kardex, CLARK, and various robotics and engineering startups.

3. How do automatic stackers handle Russia's extreme environments?

Manufacturers use advanced materials, durable design, and adaptive controls to ensure stackers perform reliably under extreme cold, humidity, and dust.

4. What are typical applications of automatic stackers in aluminum extrusion plants?

They stack, transport, and stage heavy aluminum profiles with high precision, often as part of integrated packing and warehouse systems, reducing manual labor and improving safety.

5. How can foreign buyers partner with Russian automatic stacker manufacturers and suppliers?

Foreign buyers can collaborate directly or via local agents, negotiating OEM agreements, customizing products, and integrating Russian-made stackers into their global operations.