Content Menu

● Understanding Extrusion Production

● Advantages of Extrusion Production

● Applications of Extrusion Production

● Technological Innovations in Extrusion

● Environmental Benefits

● Challenges Faced by Extrusion Production

● Conclusion

● FAQ

>> 1. What is the definition of extrusion production?

>> 2. What are the main advantages of using extrusion production?

>> 3. In which industries is extrusion production commonly used?

>> 4. How does automation impact the extrusion process?

>> 5. What environmental benefits does extrusion production offer?

● Citations:

Extrusion production is a versatile and efficient manufacturing process that has gained immense popularity across various industries. This method involves pushing material through a die to create objects with a fixed cross-sectional profile. The benefits of extrusion production are numerous, ranging from cost-effectiveness to the ability to produce complex shapes. In this article, we will delve into the intricacies of extrusion production, its advantages, applications in different manufacturing sectors, and its impact on the industry as a whole.

Understanding Extrusion Production

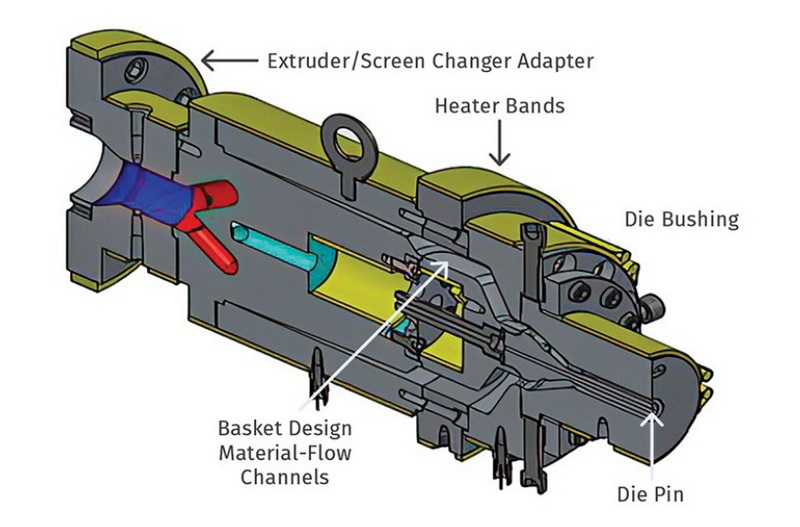

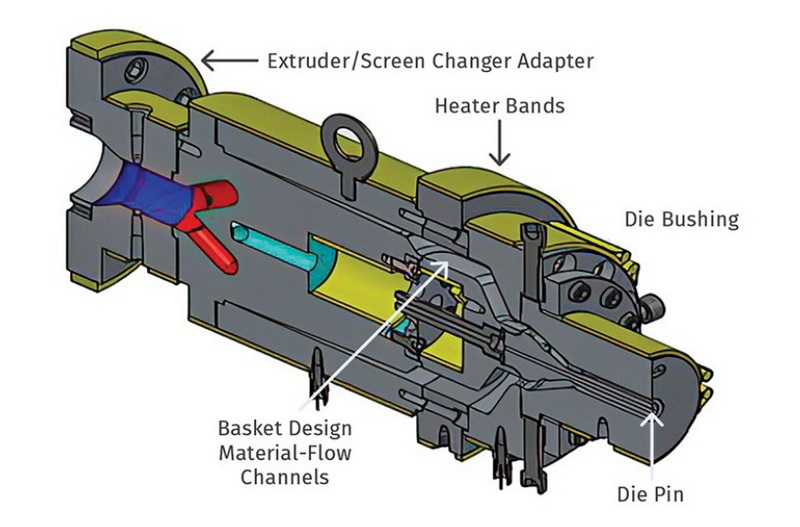

Extrusion production is defined as the process of shaping materials by forcing them through a die. This die has a specific cross-sectional profile that determines the shape of the final product. The materials commonly used in extrusion include metals, plastics, and food products. The process can be categorized into two main types: hot extrusion and cold extrusion. Hot extrusion involves heating the material to a pliable state before forcing it through the die, while cold extrusion occurs at room temperature.

The extrusion process begins with preparing the raw material, which may be in the form of pellets, powders, or ingots. The steps involved in the extrusion process typically include:

1. Material Preparation: The raw material is fed into an extruder where it is heated and melted.

2. Extrusion: The molten material is forced through a die by a ram or screw mechanism.

3. Cooling: After exiting the die, the extruded material is cooled to solidify its shape.

4. Cutting: The extruded product is cut to desired lengths for further processing or packaging.

Advantages of Extrusion Production

Extrusion production offers several advantages that make it an attractive option for manufacturers:

- Cost-Effectiveness: The continuous nature of the extrusion process minimizes waste and reduces production costs. By using less material and requiring fewer processing steps, manufacturers can achieve significant savings.

- High Efficiency: Extrusion allows for high-speed production rates, enabling manufacturers to produce large quantities of products quickly. This efficiency is crucial for meeting market demands without compromising quality.

- Versatility: One of the most significant benefits of extrusion is its versatility. It can accommodate a wide range of materials and produce various products with complex geometries that would be challenging to achieve through other manufacturing methods.

- Consistent Quality: The extrusion process ensures uniformity in product dimensions and properties, leading to high-quality outputs with minimal defects.

- Reduced Labor Costs: Automation in extrusion processes reduces the need for manual labor, further lowering operational costs.

Applications of Extrusion Production

Extrusion production finds applications across multiple industries due to its adaptability:

- Automotive Industry: Extruded components such as aluminum frames, plastic interior parts, and rubber seals are essential in vehicle manufacturing. These components benefit from lightweight yet durable materials produced through extrusion.

- Construction Industry: In construction, extruded materials like window frames, doors, and insulation profiles are widely used. The ability to create custom shapes enhances design flexibility in architectural applications.

- Food Industry: Extrusion technology plays a vital role in food processing by producing snacks like cereals and pasta. The process enhances texture and flavor while improving digestibility.

- Medical Devices: The medical industry utilizes plastic extrusion for producing tubing and components used in devices such as catheters and syringes. Precision and consistency are critical in these applications.

- Packaging Industry: Plastic extrusion is also crucial for creating packaging materials such as films, sheets, containers, and bottles. Its ability to produce lightweight yet durable packaging solutions makes it ideal for this sector.

Technological Innovations in Extrusion

The extrusion industry continues to evolve with advancements in technology:

- Automation: Modern extrusion lines incorporate automated systems for monitoring quality control and managing production processes efficiently.

- Coextrusion Technology: This innovation allows for multiple materials to be extruded simultaneously, creating composite products with enhanced properties tailored for specific applications.

- 3D Printing Integration: Some manufacturers are exploring the integration of 3D printing technologies with traditional extrusion methods to create complex geometries that were previously difficult or impossible to achieve.

- Artificial Intelligence: AI is increasingly being used to optimize various aspects of the extrusion process, from predictive maintenance to quality control, enhancing efficiency and reducing waste.

Environmental Benefits

Extrusion production also offers environmental advantages:

- Waste Reduction: The continuous nature of extrusion minimizes scrap material compared to batch processes.

- Recyclability: Many extruded materials can be recycled, contributing to sustainability efforts within manufacturing industries.

- Energy Efficiency: Modern extrusion processes often utilize energy-efficient technologies that reduce overall energy consumption during production.

Challenges Faced by Extrusion Production

While there are numerous benefits associated with extrusion production, several challenges must be addressed:

- Initial Setup Costs: Establishing an extrusion line can require significant capital investment in machinery and tooling.

- Material Limitations: Not all materials are suitable for extrusion; some may require additional processing steps or may not perform well under extreme conditions.

- Quality Control Issues: Maintaining consistent quality throughout long production runs can be challenging due to variations in raw materials or equipment performance.

Conclusion

In conclusion, extrusion production stands out as a highly beneficial manufacturing method across various industries due to its cost-effectiveness, efficiency, versatility, and ability to produce high-quality products consistently. As technological innovations continue to enhance this process, manufacturers can expect even greater capabilities and efficiencies in their operations. While challenges remain, ongoing advancements ensure that extrusion will play a critical role in shaping the future of manufacturing across diverse sectors.

FAQ

1. What is the definition of extrusion production?

Extrusion production refers to a manufacturing process where material is pushed through a die to create objects with a fixed cross-sectional profile.

2. What are the main advantages of using extrusion production?

The main advantages include cost-effectiveness, high efficiency, versatility in materials and shapes, consistent quality, and reduced labor costs.

3. In which industries is extrusion production commonly used?

Extrusion production is commonly used in industries such as automotive, construction, food processing, medical devices, packaging, and consumer goods.

4. How does automation impact the extrusion process?

Automation enhances efficiency by reducing manual labor needs and improving quality control through real-time monitoring systems.

5. What environmental benefits does extrusion production offer?

Extrusion production reduces waste due to its continuous nature and allows for recycling many extruded materials while utilizing energy-efficient technologies that lower carbon footprints.

Citations:

[1] https://www.la-plastic.com/post/why-is-extrusion-manufacturing-popular

[2] https://www.custom-profile.com/blog/exploring-the-products-made-by-extrusion/

[3] https://profileprecisionextrusions.com/the-evolution-of-aluminum-extrusions-emerging-trends-and-technologies/

[4] https://www.goodfishgroup.com/understanding-the-plastic-extrusion-process

[5] https://www.tfgusa.com/understanding-extrusion-a-fundamental-manufacturing-process/

[6] https://www.clarkrandp.com/6-common-applications-of-plastic-extrusion/

[7] https://globalaluminium.com/the-future-of-aluminium-extrusion-emerging-technologies-and-innovations/

[8] https://www.adeptcorp.com/sustainable-plastic-extrusion-practices/

[9] https://simmal.com/the-advantages-of-aluminium-extrusion-in-manufacturing/

[10] https://www.alcircle.com/news/tech-trends-driving-the-aluminium-extrusion-industry-111131

[11] https://plasticextrusiontech.net/benefits-of-plastic-extrusion/

[12] https://www.webrtcworld.com/topics/from-the-experts/articles/450597-extrusion-process-different-industries.htm

[13] https://www.petfoodprocessing.net/articles/17125-recent-advancements-edging-extrusion-tech-toward-excellence

[14] https://www.siliconeplastics.com/post/the-environmental-benefits-of-modern-plastic-extrusion-processes

[15] https://www.belcoind.com/the-benefits-of-designing-with-aluminum-extrusions/

[16] https://paulmurphyplastics.com/industry-news-blog/extrusion-process-working-types-application-advantages-and-disadvantages/

[17] https://www.inplexllc.com/blog/2023-plastic-extrusion-trends/

[18] https://www.nicerapid.com/project/the-impact-of-aluminum-extrusion-process-on-the-environment/

[19] https://www.rocalextrusions.co.uk/news/the-role-of-plastic-extrusion-in-modern-manufacturing/

[20] https://daextrusion.com/applications/

[21] https://hunterplastics.com/trends-in-plastic-extrusion-technology

[22] https://plasticextrusiontech.net/the-imperative-of-sustainability-in-the-plastic-extrusion-process/

[23] https://apenergy.com/blogs/a-complete-plastic-extrusion-process-guide-for-u-s-industrial-manufacturers/

[24] https://www.plasticsengineering.org/2024/12/top-5-extrusion-articles-of-2024-007537/

[25] https://aec.org/sustainability

[26] https://www.researchgate.net/publication/349399385_Recent_Development_Challenges_and_Prospects_of_Extrusion_Technology

[27] https://www.lightmetalage.com/news/industry-news/extrusion/aluminum-extrusion-epds-and-the-push-for-decarbonization/

[28] https://www.inplexllc.com/blog/what-industries-use-custom-plastic-extrusion/