Content Menu

● Introduction to Extrusion Machinery

>> Extrusion Machinery Meaning

● How Extrusion Machinery Works

● Types of Extrusion Machinery

● Applications of Extrusion Machinery

● Benefits of Extrusion Machinery

● Recent Advancements in Extrusion Machinery

>> Innovations in Plastic Extrusion

>> Challenges in Plastic Extrusion

>> Future of Extrusion Machinery

● Conclusion

● FAQs

>> 1. What is the meaning of extrusion machinery?

>> 2. How does extrusion machinery work?

>> 3. What are the types of extrusion machinery?

>> 4. What are the applications of extrusion machinery?

>> 5. What are the benefits of using extrusion machinery?

● Citations:

Extrusion machinery is a fundamental tool in various manufacturing industries, including plastics, metals, ceramics, and even food production. The process involves forcing raw materials through a die to create products with specific cross-sectional profiles. This article will delve into the meaning and operation of extrusion machinery, exploring its applications, types, and benefits.

Introduction to Extrusion Machinery

Extrusion machinery is designed to shape materials by pushing them through a die, which gives the final product its desired shape. This process is widely used in industries such as plastics manufacturing, where it produces items like pipes, profiles, and films.

Extrusion Machinery Meaning

The term "extrusion machinery meaning" refers to the equipment used in the extrusion process. This machinery is crucial for transforming raw materials into continuous products with uniform cross-sections. The extrusion process involves several key components:

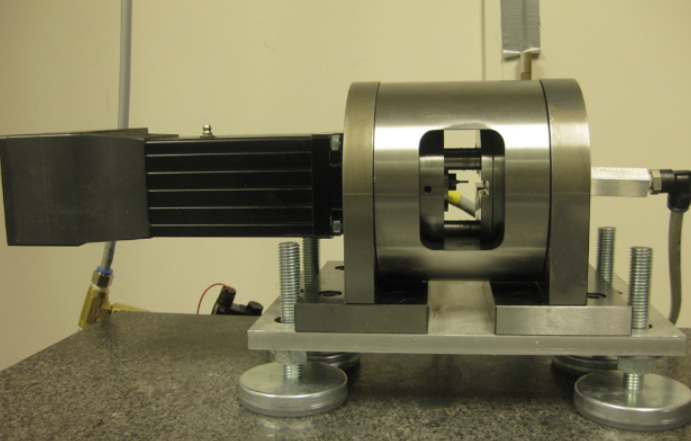

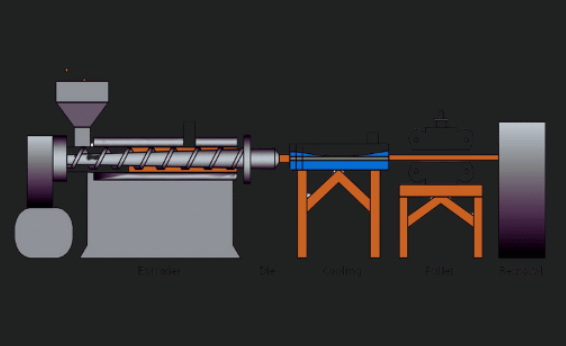

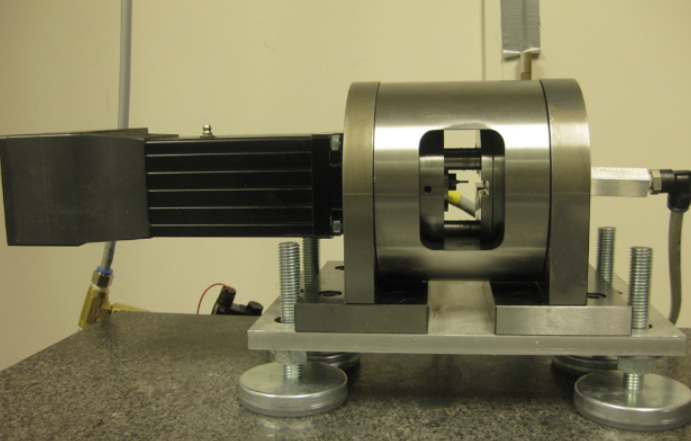

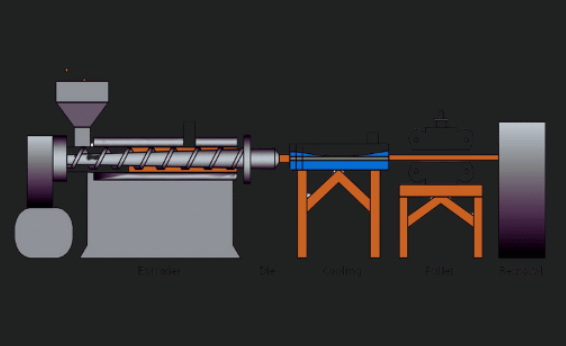

1. Extruder: This is the heart of the extrusion machinery, responsible for heating and mixing the raw materials.

2. Die: The die shapes the material into the desired form.

3. Cooling System: This system solidifies the extruded material.

How Extrusion Machinery Works

The operation of extrusion machinery involves several steps:

1. Material Feeding: Raw materials, often in the form of granules or powder, are fed into the extruder through a hopper.

2. Heating and Melting: The material is heated and melted by the rotating screw within the extruder barrel.

3. Shaping: The molten material is forced through a die, which gives it the desired shape.

4. Cooling: The shaped material is cooled to solidify and maintain its form.

Types of Extrusion Machinery

Extrusion machinery can be categorized based on the type of extrusion process:

- Single-Screw Extruders: Used for simple extrusion tasks, these machines have one screw.

- Twin-Screw Extruders: Offer better mixing and heat transfer, ideal for complex formulations.

Applications of Extrusion Machinery

Extrusion machinery is versatile and used across various industries:

- Plastics Industry: Extensively used to produce a variety of plastic products, including pipes, sheets, films, and profiles. The process allows for precise control over the shape and properties of the final product[1][3].

- Food Industry: Food extruders are used to produce snacks, cereals, pasta, and pet foods. The extrusion process can modify the texture, shape, and nutritional content of food products, making it a valuable tool for food manufacturers[1][3].

- Metals Industry: Metal extrusion is used to create complex shapes and profiles from metals such as aluminum, copper, and steel. This process is commonly used in the automotive, aerospace, and construction industries[1][3].

- Ceramics and Composites: Extrusion is also used in processing ceramics and composites[3].

Benefits of Extrusion Machinery

The use of extrusion machinery offers several advantages:

- High Production Rates: Enables mass production of continuous products.

- Material Flexibility: Can process a wide range of materials.

- Complex Shapes: Allows for the creation of intricate profiles.

Recent Advancements in Extrusion Machinery

Recent innovations in extrusion technology are enhancing efficiency, precision, and sustainability:

- Differential Velocity Sideways Extrusion (DVSE): Enables curved metal profiles with fine grains and high strength, ideal for aerospace and automotive applications[2].

- Supercritical Fluid Extrusion (SCFX): Uses supercritical CO2 in food processing to foam at lower temperatures, preserving nutrients and creating unique textures[2].

- 3D Printing Integration: Combining 3D printing with extrusion allows for customized, complex shapes in polymers and metals, boosting prototyping and small-scale production[2].

- Energy Efficiency and Sustainability: New extruders reduce energy use, incorporate renewables, and improve recycling, supporting sustainable manufacturing[2].

Innovations in Plastic Extrusion

In the plastics industry, advancements include the use of servo-driven extruders for precise control and high-efficiency heaters for reduced energy consumption[6]. Artificial Intelligence (AI) plays a pivotal role in optimizing extrusion processes by analyzing vast amounts of data and making real-time adjustments to parameters like temperature and pressure[6].

Challenges in Plastic Extrusion

Despite its benefits, plastic extrusion faces challenges such as material selection, maintaining dimensional accuracy, and managing temperature fluctuations[8]. Overcoming these challenges requires regular equipment maintenance, advanced monitoring systems, and collaboration with material experts[8].

Future of Extrusion Machinery

The future of extrusion technology is expected to be shaped by increased automation, advanced controls, and Industry 4.0 developments. By 2030, OEMs foresee better control units, greater adoption of Industry 4.0 technology, and more automation, enhancing efficiency and reducing labor costs[5].

Conclusion

Extrusion machinery plays a vital role in modern manufacturing by transforming raw materials into products with precise shapes. Its applications span multiple industries, making it an indispensable tool for producing a variety of goods. Understanding the meaning and operation of extrusion machinery is crucial for optimizing production processes and ensuring product quality.

FAQs

1. What is the meaning of extrusion machinery?

Extrusion machinery refers to the equipment used to shape materials by forcing them through a die, creating products with uniform cross-sections. This process is essential in industries like plastics and metals.

2. How does extrusion machinery work?

Extrusion machinery works by feeding raw materials into an extruder, where they are heated and melted. The molten material is then pushed through a die to achieve the desired shape and cooled to solidify.

3. What are the types of extrusion machinery?

Extrusion machinery can be categorized into single-screw and twin-screw extruders. Single-screw extruders are used for straightforward tasks, while twin-screw extruders offer better mixing and heat transfer for complex processes.

4. What are the applications of extrusion machinery?

Extrusion machinery is used in various industries, including plastics manufacturing for pipes and profiles, the food industry for pastries, and the metal industry for creating metal profiles and tubes.

5. What are the benefits of using extrusion machinery?

The benefits include high production rates, material flexibility, and the ability to create complex shapes. Extrusion machinery also allows for the production of multi-layered products through co-extrusion.

Citations:

[1] https://engitech.in/extrusion-machines-and-extruders-guide/

[2] https://uplastech.com/advancements-extrusion-machinery/

[3] https://www.yjing-extrusion.com/what-types-of-post-extrusion-equipment-are-available-for-different-industries.html

[4] https://deltaplastik.com/blog/challenges-and-solutions-in-plastic-extrusion-process

[5] https://www.plasticsmachinerymanufacturing.com/extrusion/article/21161172/oems-forecast-high-tech-future-for-extrusion

[6] https://www.wevolver.com/article/extruding-plastic

[7] https://yamunaind.com/innovation-spotlight-recent-advancements-in-aluminium-extrusion-technology/

[8] https://www.inplexllc.com/blog/overcoming-common-challenges-in-plastic-extrusion-projects/

[9] https://www.rocalextrusions.co.uk/news/applications-of-plastic-extrusion/

[10] https://www.marketreportanalytics.com/reports/plastic-compounding-and-extrusion-machines-21908

[11] https://extal.com/en/the-evolution-of-aluminum-extrusion-techniques-with-extal/

[12] https://www.yjing-extrusion.com/what-are-the-latest-innovations-in-automatic-extrusion-machines.html

[13] https://www.linkedin.com/pulse/7-common-applications-industrial-aluminum

[14] https://kindle-tech.com/faqs/what-are-the-disadvantages-of-the-extrusion-process

[15] https://blog.tbrc.info/2025/03/extrusion-machinery-industry-2/

[16] https://www.lernermoldedplastics.com/the-comprehensive-guide-to-advanced-extrusion-techniques/

[17] https://www.ptonline.com/articles/get-ready-to-be-blown-away-with-new-extrusion-technology

[18] https://daextrusion.com/applications/

[19] https://www.bausano.com/en/press-and-news/common-problems-in-the-plastic-extrusion-process

[20] https://hunterplastics.com/trends-in-plastic-extrusion-technology