Content Menu

● Introduction to Automatic Extrusion Machines

>> Key Features of Automatic Extrusion Machines

● Applications of Automatic Extrusion Machines

>> Automotive Industry

>> Construction Industry

>> Aerospace Industry

● How Automatic Extrusion Machines Improve Efficiency

>> High Production Speed

>> Reduced Material Waste

>> Consistent Product Quality

>> Automation and Labor Efficiency

>> Flexible Material Processing

● Enhancing Efficiency with Technology

>> Predictive Maintenance

>> Real-Time Monitoring

>> Data-Driven Decision Making

● Case Studies: Improving Efficiency with Automatic Extrusion

>> Aluminum Extrusion Plant Case Study

● Conclusion

● FAQ

>> 1. What are the primary benefits of using automatic extrusion machines?

>> 2. How do automatic extrusion machines improve product quality?

>> 3. What role does automation play in enhancing efficiency?

>> 4. How do automatic extrusion machines contribute to environmental sustainability?

>> 5. What industries benefit most from automatic extrusion machines?

● Citations:

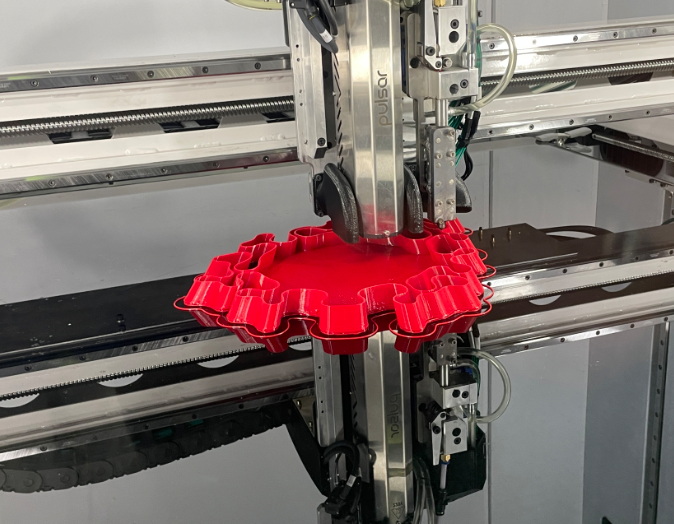

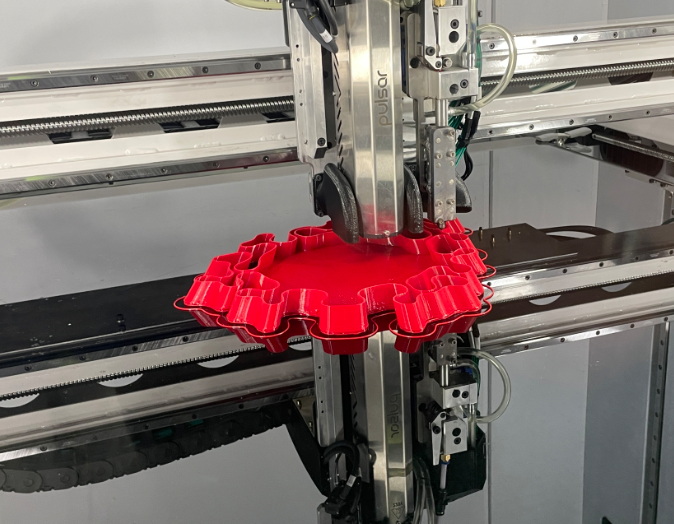

Automatic extrusion machines have revolutionized the manufacturing industry by significantly enhancing production efficiency across various sectors, including plastics, metals, and composites. These machines leverage advanced automation technologies, such as AI and IoT, to optimize production parameters in real-time, thereby reducing waste and improving product quality. In this article, we will delve into the ways automatic extrusion machines improve production efficiency and explore their applications in different industries.

Introduction to Automatic Extrusion Machines

Automatic extrusion machines are designed to automate the extrusion process, which involves forcing molten material through a die to create a specific shape. This process is widely used in industries such as automotive, construction, and consumer goods. The integration of automation in extrusion machines allows for continuous operation with minimal human intervention, leading to increased productivity and reduced labor costs.

Key Features of Automatic Extrusion Machines

1. High-Speed Production: Automatic extrusion machines can process large volumes of material quickly, enabling manufacturers to meet high demand without compromising product quality. For example, Adremac's extruders operate at high speeds, ensuring consistent product quality while reducing material waste[2].

2. Real-Time Monitoring and Control: These machines are equipped with real-time monitoring systems that allow operators to detect anomalies and make adjustments promptly. This feature is crucial for maintaining optimal production conditions and ensuring consistent product quality[1][6].

3. Energy Efficiency: Modern extrusion machines are designed to be energy-efficient, reducing the carbon footprint of the manufacturing process. This is particularly important for industries aiming to minimize their environmental impact[7].

4. Material Optimization: Automatic extrusion machines optimize material usage, reducing waste and making production more environmentally friendly[2][7].

5. Flexibility in Material Processing: These machines can handle a variety of materials, including thermoplastics, metals, and composite materials, offering versatility in product design and manufacturing[7].

Applications of Automatic Extrusion Machines

Automatic extrusion machines are used in various industries due to their efficiency and versatility:

Automotive Industry

In the automotive sector, automatic extrusion is used to produce lightweight aluminum profiles for vehicle frames. This contributes to improved fuel efficiency and reduced emissions, aligning with the industry's focus on sustainability[7].

Construction Industry

PVC pipes produced through automatic extrusion are widely used in plumbing systems due to their durability and resistance to corrosion. This application highlights the machine's ability to produce high-quality products consistently[7].

Aerospace Industry

Composite extrusion is utilized in the aerospace industry to manufacture components for aircraft, where high strength-to-weight ratios are critical for performance and safety[7].

How Automatic Extrusion Machines Improve Efficiency

High Production Speed

Automatic extrusion machines can operate at high speeds, allowing businesses to meet increasing demand without sacrificing product quality. This capability is particularly beneficial in industries with fluctuating demand patterns[2].

Reduced Material Waste

These machines are engineered to optimize raw material usage, reducing waste during the manufacturing process. This not only leads to cost savings but also makes production more environmentally friendly[2][7].

Consistent Product Quality

The precision of extruder machines ensures uniformity in the final product, with consistent wall thickness, material strength, and smooth finishes. This reliability is crucial for industries where quality control is a top priority[2].

Automation and Labor Efficiency

Automatic extrusion machines automate the production process, reducing the need for manual labor. This not only cuts labor costs but also improves the safety and reliability of manufacturing operations, as the machines can run continuously with minimal supervision[2][7].

Flexible Material Processing

These machines can handle a variety of materials, offering flexibility in product design and manufacturing. This versatility is beneficial for industries that require diverse product offerings[7].

Enhancing Efficiency with Technology

The integration of advanced technologies such as AI and IoT in automatic extrusion machines further enhances efficiency by optimizing production parameters in real-time. This includes predictive maintenance, real-time monitoring, and data-driven decision-making[7].

Predictive Maintenance

Predictive maintenance allows for proactive maintenance scheduling based on real-time data, reducing downtime and improving overall equipment effectiveness (OEE)[6].

Real-Time Monitoring

Real-time monitoring systems enable operators to quickly identify and address production anomalies, ensuring consistent product quality and minimizing waste[1][6].

Data-Driven Decision Making

Access to real-time data allows manufacturers to make informed decisions about production processes, optimizing efficiency and reducing costs[6].

Case Studies: Improving Efficiency with Automatic Extrusion

Aluminum Extrusion Plant Case Study

An aluminum extrusion plant significantly improved its overall efficiency and reduced waste by implementing advanced monitoring systems. The plant's OEE increased from 20% to 58% within the first year, demonstrating the potential of automation in enhancing production efficiency[3].

Conclusion

Automatic extrusion machines have transformed the manufacturing landscape by offering high efficiency, consistency, and cost-effectiveness. Their ability to process a wide range of materials, reduce waste, and operate with minimal labor intervention makes them indispensable in industries such as automotive, construction, and aerospace. As technology continues to evolve, we can expect even more sophisticated automation systems and expanded capabilities in the field of extrusion.

FAQ

1. What are the primary benefits of using automatic extrusion machines?

Automatic extrusion machines offer several benefits, including high-speed production, reduced material waste, consistent product quality, and labor efficiency. They also provide flexibility in material processing and are energy-efficient, reducing the environmental impact of manufacturing[2][7].

2. How do automatic extrusion machines improve product quality?

These machines ensure consistent product quality through precise control over production parameters such as temperature, pressure, and speed. Real-time monitoring systems allow for immediate adjustments, maintaining optimal production conditions[1][6].

3. What role does automation play in enhancing efficiency?

Automation in extrusion machines reduces the need for manual labor, improves safety, and allows for continuous operation with minimal supervision. It also enables real-time monitoring and predictive maintenance, further enhancing efficiency and reducing downtime[2][7].

4. How do automatic extrusion machines contribute to environmental sustainability?

Automatic extrusion machines contribute to environmental sustainability by optimizing material usage, reducing waste, and utilizing energy-efficient technologies. This minimizes the carbon footprint of the manufacturing process[7].

5. What industries benefit most from automatic extrusion machines?

Industries such as automotive, construction, and aerospace benefit significantly from automatic extrusion machines due to their need for high-quality, consistent products. These machines help meet demand efficiently while reducing costs and environmental impact[7].

Citations:

[1] https://www.faygounion.com/news/5-ways-to-improve-efficiency-in-plastic-extrusion-lines/

[2] https://www.adremac.com/how-extruders-enhance-efficiency-in-industrial-manufacturing/

[3] https://www.10in6.com/case-studies/aluminum-extrusion-plant-case-study/

[4] https://www.alamy.com/stock-photo/extrusion-machine.html

[5] https://www.youtube.com/watch?v=P8BWQBP4Vhk

[6] https://www.spssolutions.nl/how-efficiently-runs-your-extrusion-line/?lang=en

[7] https://www.yjing-extrusion.com/what-is-automatic-extrusion-and-how-does-it-work.html

[8] https://www.yjing-extrusion.com/how-does-extrusion-production-benefit-manufacturing-industries.html

[9] https://www.youtube.com/watch?v=Y75IQksBb0M

[10] https://www.youtube.com/watch?v=y77H1aQjaoU

[11] https://www.mastermover.com/case-studies/not-a-second-wasted-with-agv-technology/

[12] https://www.linkedin.com/pulse/how-improve-working-efficiency-aluminum-profile-extrusion-machine-

[13] https://www.armstrongex.com/the-benefits-of-fully-automatic-tuber-machines-for-your-manufacturing-business

[14] https://www.atieuno.com/project/extrusion-management-system-case-study/

[15] https://reifenhauser.com/en/company/media/news-and-stories/success-story/increase-productivity-plastics-extrusion

[16] https://www.bgplast.it/https-www-bgplast-it-automation-in-extrusion/

[17] https://www.indusedu.org/pdfs/IJREISS/IJREISS_4130_56414.pdf

[18] https://www.prm-taiwan.com/blog/advantages-aba-coextrusion-blown-film-machine_411

[19] https://www.prm-taiwan.com/blog/Medical-Tube-Extrusion-Line-Key-Insights-and-Case-Studies_531

[20] https://www.dwellextrusion.com/de/5-key-benefits-of-using-automatic-thermoforming-equipment/

[21] https://www.deskera.com/blog/the-role-of-automation-in-plastic-production/

[22] https://www.shutterstock.com/search/extrusion-machine

[23] https://stock.adobe.com/search?k=extruder+machine

[24] https://www.istockphoto.com/photos/extruder-machine

[25] https://www.youtube.com/playlist?list=PL8B1r8zT-52EYf149q_TDvFNg0-lzLsYA

[26] https://stock.adobe.com/search?k=extrusion+machine

[27] https://www.youtube.com/watch?v=Djy6SCSotgg

[28] https://www.shutterstock.com/search/extrusion-press

[29] https://www.youtube.com/watch?v=yVNs0_9GTd8

[30] https://www.battenfeld-cincinnati.com/company/press/detail/show/well-on-the-way-to-fully-automatic-extrusion-lines

[31] https://www.istockphoto.com/photos/extrusion-technology

[32] https://www.youtube.com/playlist?list=PLoqtn9Uh6SkXrtb6SUVZmMAsYAXbNjgDE

[33] http://journalmt.com/artkey/mft-202101-0006_improving-overall-equipment-effectiveness-oee-of-extrusion-machine-using-lean-manufacturing-approach.php

[34] https://www.linkedin.com/pulse/some-ways-improving-extrusion-production-efficiency-stan-hua

[35] https://jieyatwinscrew.com/blog/exploring-the-world-of-extrusion-machines-understanding-the-basics-and-benefits/

[36] https://drts.com/extruder-machines-smart-manufacturing-standards/