Content Menu

● Introduction to Aluminum Extrusion Presses

● Understanding the Aluminum Extrusion Process

● The Market for Aluminum Extrusion Presses

● Advancements in Extrusion Press Technology

● Choosing the Right Aluminum Extrusion Press

● Custom Aluminum Extrusions: Tailoring to Industry Needs

● The Role of Aluminum Profile Manufacturing in Sustainability

● Maintenance and Longevity of Extrusion Presses

● The Future of Aluminum Extrusion Technology

● Conclusion

● Frequently Asked Questions

Introduction to Aluminum Extrusion Presses

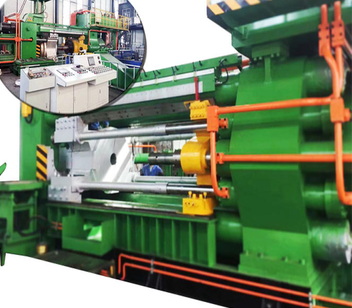

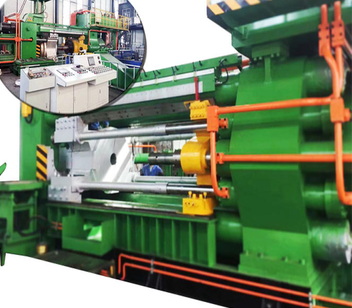

In the world of metal forming, aluminum extrusion presses stand as titans of industry, shaping the very foundation of modern manufacturing. These powerful machines are the unsung heroes behind countless products we use daily, from sleek smartphone casings to robust aerospace components. As the demand for lightweight, durable, and cost-effective materials continues to soar, the aluminum extrusion press for sale market has become a hotbed of innovation and opportunity.

Understanding the Aluminum Extrusion Process

At its core, the aluminum extrusion process is a marvel of engineering. It involves forcing heated aluminum billets through a die with a specific cross-sectional profile. This process creates long, precisely shaped pieces that can be cut to desired lengths. The versatility of this method allows for the creation of complex shapes that would be difficult or impossible to achieve through other manufacturing techniques.

The heart of this process is the hydraulic extrusion press, a behemoth of industrial machinery capable of exerting immense force to shape metal. These presses come in various sizes, with some of the largest capable of producing forces up to 15,000 tons or more. The choice of press size depends on the desired output, with larger presses typically used for high-volume aluminum production.

The Market for Aluminum Extrusion Presses

The market for aluminum extrusion presses is diverse and dynamic. From small-scale operations to massive industrial complexes, there's a press for every need. When considering an aluminum extrusion press for sale, buyers must weigh factors such as production capacity, energy efficiency, and automation capabilities.

Used aluminum extrusion equipment has become an attractive option for many businesses looking to enter the market or expand their operations without the hefty price tag of new machinery. However, it's crucial to thoroughly inspect and evaluate any used equipment to ensure it meets current industry standards and production requirements.

Advancements in Extrusion Press Technology

The field of industrial extrusion machinery is constantly evolving. Modern presses incorporate advanced hydraulic systems, precision controls, and sophisticated software to optimize the extrusion process. These technological advancements have led to significant improvements in:

1. Energy efficiency

2. Production speed

3. Material utilization

4. Product quality

5. Customization capabilities

High-volume aluminum production has become more accessible than ever, thanks to these innovations. Manufacturers can now produce complex profiles with tighter tolerances and better surface finishes, meeting the exacting standards of industries such as automotive and aerospace.

Choosing the Right Aluminum Extrusion Press

Selecting the appropriate hydraulic extrusion press is a critical decision for any metal forming operation. Factors to consider include:

- Production volume requirements

- Types of profiles to be extruded

- Available floor space

- Budget constraints

- Energy consumption

- Maintenance needs

For those in the market for metal forming equipment, it's essential to work with reputable suppliers who can provide detailed extrusion press specifications and support throughout the selection process.

Custom Aluminum Extrusions: Tailoring to Industry Needs

One of the most significant advantages of aluminum extrusion is the ability to create custom profiles. This flexibility allows industries to design components that perfectly fit their needs, whether it's a heat sink for electronics or a structural member for construction.

Custom aluminum extrusions have found applications in:

- Automotive parts

- Building and construction

- Consumer electronics

- Renewable energy systems

- Furniture and fixtures

- Transportation

The ability to produce these custom shapes efficiently and cost-effectively has made aluminum extrusion a preferred manufacturing method across various sectors.

The Role of Aluminum Profile Manufacturing in Sustainability

As the world moves towards more sustainable practices, aluminum profile manufacturing has taken center stage. Aluminum is infinitely recyclable without losing its properties, making it an environmentally friendly choice for many applications. The extrusion process itself is relatively energy-efficient compared to other metal forming techniques, especially when using modern, optimized equipment.

Moreover, the lightweight nature of aluminum profiles contributes to fuel efficiency in transportation applications, further enhancing its eco-friendly credentials. As such, investing in an aluminum extrusion press for sale can be seen as a step towards more sustainable manufacturing practices.

Maintenance and Longevity of Extrusion Presses

To ensure the longevity and optimal performance of an aluminum extrusion press, regular maintenance is crucial. This includes:

- Routine inspections of hydraulic systems

- Lubrication of moving parts

- Cleaning and replacement of filters

- Calibration of control systems

- Monitoring of wear on critical components

With proper care, an extrusion press can remain productive for decades, making it a wise long-term investment for any manufacturing operation.

The Future of Aluminum Extrusion Technology

The future of aluminum extrusion technology looks bright, with ongoing research and development focused on:

1. Improved die designs for more complex profiles

2. Advanced alloys for enhanced material properties

3. Integration of artificial intelligence for process optimization

4. Increased automation and robotics in extrusion lines

5. Development of micro-extrusion techniques for miniature components

These advancements promise to expand the capabilities of aluminum extrusion, opening up new markets and applications for this versatile manufacturing process.

Conclusion

The aluminum extrusion press stands as a cornerstone of modern manufacturing, enabling the production of complex, lightweight, and durable components essential to countless industries. Whether you're in the market for a new press or considering used aluminum extrusion equipment, understanding the intricacies of this technology is crucial for making informed decisions.

As we look to the future, the aluminum extrusion process will continue to evolve, driven by demands for greater efficiency, sustainability, and innovation. For businesses and entrepreneurs alike, the aluminum extrusion press for sale market represents not just an investment in machinery, but in the future of manufacturing itself.

Frequently Asked Questions

1. Q: What is the typical lifespan of an aluminum extrusion press?

A: With proper maintenance, an aluminum extrusion press can last 20-30 years or more. Regular upkeep and timely repairs are crucial for maximizing the lifespan of the equipment.

2. Q: How does the size of an extrusion press affect its capabilities?

A: Larger presses generally have higher force capacities, allowing for the extrusion of larger profiles and harder alloys. They are also typically capable of higher production volumes. Smaller presses are more suitable for specialized or lower-volume production runs.

3. Q: What are the key differences between new and used aluminum extrusion equipment?

A: New equipment often features the latest technology, higher energy efficiency, and full warranties. Used equipment can be more cost-effective but may require more maintenance and lack some modern features. The choice depends on budget, production needs, and desired technological capabilities.

4. Q: How has automation impacted the aluminum extrusion process?

A: Automation has significantly improved the efficiency and consistency of aluminum extrusion. It has led to reduced labor costs, increased production speeds, and improved quality control. Modern presses often feature automated billet loading, profile handling, and even packaging systems.

5. Q: What environmental benefits does aluminum extrusion offer?

A: Aluminum extrusion is an environmentally friendly process due to the material's recyclability. Extruded aluminum products can be recycled indefinitely without losing quality. Additionally, the lightweight nature of aluminum profiles contributes to fuel efficiency in transportation applications, reducing overall carbon footprint.