Content Menu

● The Basics of Aluminum Extrusion

● Introducing Aluminum Extrusion Machining Centers

● How Aluminum Extrusion Machining Centers Enhance Efficiency

>> 1. Reduced Setup Time

>> 2. Increased Precision and Accuracy

>> 3. Versatility in Part Production

>> 4. Automation and Reduced Labor Costs

>> 5. Improved Material Utilization

● Real-World Applications and Case Studies

>> Automotive Industry

>> Aerospace Sector

>> Construction and Architecture

● Challenges and Considerations

● Future Trends in Aluminum Extrusion Machining

● Conclusion

● Frequently Asked Questions

>> 1. What is the maximum size of aluminum profiles that can be machined using an aluminum extrusion machining center?

>> 2. How does an aluminum extrusion machining center compare to traditional CNC machines in terms of efficiency?

>> 3. What types of industries benefit most from using aluminum extrusion machining centers?

>> 4. How does the cost of producing parts with an aluminum extrusion machining center compare to traditional manufacturing methods?

>> 5. What level of operator expertise is required to run an aluminum extrusion machining center effectively?

● Citations:

Aluminum extrusion machining centers have revolutionized the manufacturing industry by significantly enhancing production efficiency, precision, and versatility. These advanced machines combine the benefits of aluminum extrusion with state-of-the-art CNC technology, resulting in a powerful tool for creating complex aluminum profiles with unparalleled accuracy and speed. In this article, we'll explore how aluminum extrusion machining centers improve production efficiency and why they have become an indispensable asset for manufacturers across various industries.

The Basics of Aluminum Extrusion

Before delving into the specifics of aluminum extrusion machining centers, it's essential to understand the fundamental process of aluminum extrusion. Aluminum extrusion is a manufacturing technique that involves forcing heated aluminum through a die to create profiles with specific cross-sectional shapes. This process allows for the creation of complex shapes that would be difficult or impossible to achieve through traditional manufacturing methods.

The aluminum extrusion process typically involves the following steps:

1. Heating the aluminum billet

2. Placing the heated billet into the extrusion press

3. Applying pressure to force the aluminum through the die

4. Cooling and stretching the extruded profile

5. Cutting the profile to the desired length

While this process is highly efficient for creating long, continuous profiles, it often requires additional machining to achieve the final desired shape and features. This is where aluminum extrusion machining centers come into play.

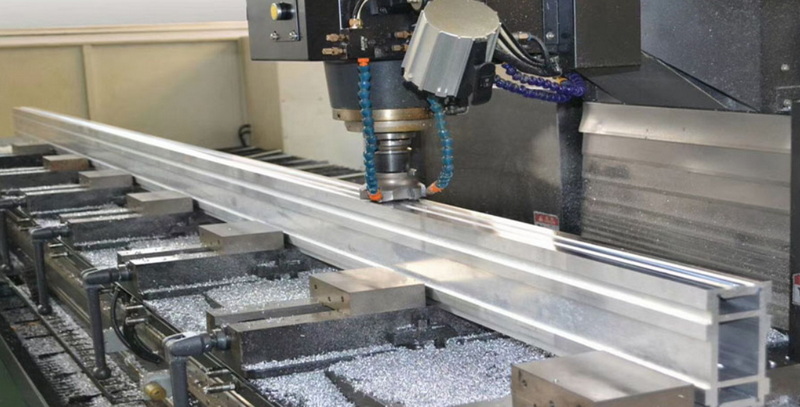

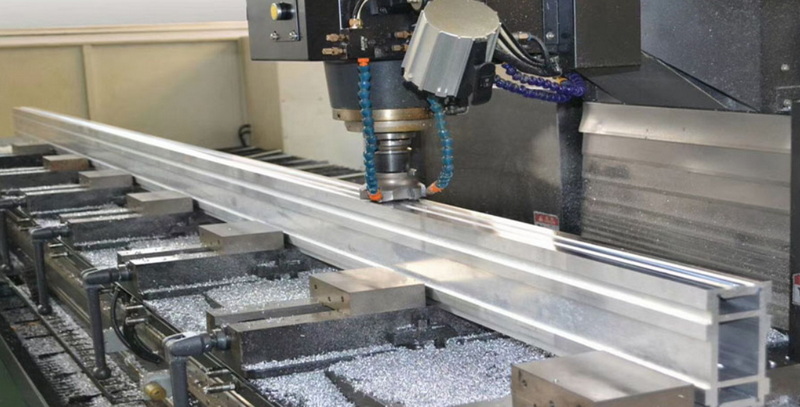

Introducing Aluminum Extrusion Machining Centers

An aluminum extrusion machining center is a specialized CNC (Computer Numerical Control) machine designed to perform various machining operations on extruded aluminum profiles. These centers combine the benefits of extrusion with advanced machining capabilities, allowing manufacturers to create complex, precision-engineered aluminum parts with minimal setup time and maximum efficiency.

Key features of aluminum extrusion machining centers include:

- Multi-axis machining capabilities (typically 3-5 axes)

- Automatic tool changers for seamless operation

- High-speed spindles for rapid material removal

- Advanced control systems for precise movements

- Integrated cooling systems for temperature management

- Automated material handling systems

These features work together to create a highly efficient and versatile manufacturing solution that can significantly improve production efficiency.

How Aluminum Extrusion Machining Centers Enhance Efficiency

Aluminum extrusion machining centers offer numerous advantages that contribute to improved production efficiency. Let's explore some of the key ways these machines optimize the manufacturing process:

1. Reduced Setup Time

One of the most significant benefits of aluminum extrusion machining centers is their ability to reduce setup time dramatically. Traditional manufacturing processes often require multiple machine setups to complete a single part, leading to increased production time and potential for errors. With an aluminum extrusion machining center, manufacturers can perform multiple operations in a single setup, significantly reducing overall production time.

2. Increased Precision and Accuracy

Aluminum extrusion machining centers utilize advanced CNC technology to achieve exceptional precision and accuracy. These machines can maintain tight tolerances consistently, ensuring that each part meets exact specifications. This level of precision not only improves the quality of the final product but also reduces waste and rework, further enhancing production efficiency.

3. Versatility in Part Production

The combination of extrusion and machining capabilities allows for the creation of complex parts that would be difficult or impossible to produce using traditional methods. Aluminum extrusion machining centers can perform a wide range of operations, including:

- Milling

- Drilling

- Tapping

- Cutting

- Engraving

- Chamfering

This versatility enables manufacturers to produce a diverse range of parts without the need for multiple specialized machines, streamlining the production process and reducing equipment costs.

4. Automation and Reduced Labor Costs

Aluminum extrusion machining centers are highly automated, requiring minimal human intervention during operation. This automation not only reduces labor costs but also minimizes the potential for human error, leading to more consistent and reliable production. Additionally, these machines can often run unattended for extended periods, allowing for 24/7 production capabilities and increased output.

5. Improved Material Utilization

By combining extrusion and machining processes, aluminum extrusion machining centers can optimize material utilization. The extrusion process allows for the creation of near-net-shape profiles, reducing the amount of material that needs to be removed during machining. This results in less waste and lower material costs, contributing to overall production efficiency.

Real-World Applications and Case Studies

To better understand the impact of aluminum extrusion machining centers on production efficiency, let's examine some real-world applications and case studies:

Automotive Industry

In the automotive industry, aluminum extrusion machining centers have revolutionized the production of lightweight, high-strength components. For example, a leading automotive manufacturer implemented an aluminum extrusion machining center to produce complex structural components for electric vehicles. The result was a 40% reduction in production time and a 25% decrease in material waste compared to traditional manufacturing methods.

Aerospace Sector

The aerospace industry relies heavily on precision-engineered aluminum components. An aerospace parts supplier integrated an aluminum extrusion machining center into their production line, enabling them to produce intricate wing spars with unprecedented efficiency. The new system reduced production time by 60% while maintaining the strict tolerances required for aerospace applications.

Construction and Architecture

Aluminum extrusion machining centers have also found applications in the construction and architecture sectors. A manufacturer of custom aluminum window frames implemented a machining center to streamline their production process. The new system allowed them to produce custom frames 50% faster than their previous method, with improved accuracy and consistency.

Challenges and Considerations

While aluminum extrusion machining centers offer numerous benefits, there are some challenges and considerations to keep in mind:

1. Initial Investment: These machines represent a significant upfront investment, which may be a barrier for smaller manufacturers.

2. Training Requirements: Operators require specialized training to maximize the potential of these advanced machines.

3. Maintenance: Regular maintenance is crucial to ensure optimal performance and longevity of the equipment.

4. Design Optimization: To fully leverage the capabilities of aluminum extrusion machining centers, parts may need to be redesigned to take advantage of the extrusion process.

Future Trends in Aluminum Extrusion Machining

As technology continues to advance, we can expect to see further improvements in aluminum extrusion machining centers. Some emerging trends include:

- Integration of artificial intelligence for predictive maintenance and process optimization

- Enhanced simulation capabilities for improved part design and process planning

- Increased use of hybrid manufacturing techniques, combining additive and subtractive processes

- Development of more environmentally friendly and energy-efficient machining processes

Conclusion

Aluminum extrusion machining centers have proven to be game-changers in the manufacturing industry, offering significant improvements in production efficiency, precision, and versatility. By combining the benefits of aluminum extrusion with advanced CNC machining capabilities, these machines enable manufacturers to produce complex, high-quality parts with unprecedented speed and accuracy.

The advantages of reduced setup time, increased precision, versatility in part production, automation, and improved material utilization make aluminum extrusion machining centers an invaluable asset for companies looking to stay competitive in today's fast-paced manufacturing landscape. As technology continues to evolve, we can expect these machines to play an increasingly important role in shaping the future of manufacturing across various industries.

Frequently Asked Questions

1. What is the maximum size of aluminum profiles that can be machined using an aluminum extrusion machining center?

The maximum size of aluminum profiles that can be machined depends on the specific machine's capabilities. However, many aluminum extrusion machining centers can accommodate profiles up to 30 feet in length and with cross-sections of up to 12 inches by 12 inches. Some specialized machines can handle even larger profiles.

2. How does an aluminum extrusion machining center compare to traditional CNC machines in terms of efficiency?

Aluminum extrusion machining centers are generally more efficient than traditional CNC machines for producing aluminum parts, especially those with complex profiles. They combine the benefits of extrusion and machining, reducing setup time and material waste. In many cases, an aluminum extrusion machining center can complete a part in a single setup that would require multiple setups on traditional CNC machines.

3. What types of industries benefit most from using aluminum extrusion machining centers?

While aluminum extrusion machining centers can benefit a wide range of industries, they are particularly valuable in sectors that require complex, lightweight, and high-strength aluminum components. Some of the industries that benefit most include:

- Automotive

- Aerospace

- Construction and architecture

- Electronics

- Renewable energy (solar and wind power)

- Transportation (rail and marine)

4. How does the cost of producing parts with an aluminum extrusion machining center compare to traditional manufacturing methods?

The cost of producing parts with an aluminum extrusion machining center can be significantly lower than traditional manufacturing methods, especially for medium to high-volume production runs. While the initial investment in the machine may be higher, the reduced setup time, improved material utilization, and increased automation lead to lower per-part costs over time. Additionally, the ability to produce complex parts in a single setup can eliminate the need for multiple machines or processes, further reducing overall production costs.

5. What level of operator expertise is required to run an aluminum extrusion machining center effectively?

Operating an aluminum extrusion machining center requires a combination of skills, including knowledge of CNC programming, understanding of aluminum extrusion processes, and familiarity with CAD/CAM software. While the level of expertise required can vary depending on the complexity of the parts being produced, most operators will need specialized training to effectively run and maintain these advanced machines. Many manufacturers offer comprehensive training programs to ensure operators can maximize the potential of their aluminum extrusion machining centers.

Citations:

[1] https://www.linkedin.com/pulse/how-improve-working-efficiency-aluminum-profile-extrusion-machine-

[2] https://www.linkedin.com/pulse/some-ways-improving-extrusion-production-efficiency-stan-hua

[3] https://www.tensilemillcnc.com/blog/12-major-benefits-of-aluminum-extrusions

[4] https://americandouglasmetals.com/cnc-machining-center/

[5] https://www.youtube.com/watch?v=iiGlq7408ME

[6] https://demacmachine.com/aluminum-extrusion-machining-center/

[7] https://starext.com/news/aluminum-extrusion-finishing-fabrication-frequently-asked-questions-faq

[8] https://americandouglasmetals.com/2024/05/19/understanding-the-aluminum-extrusion-process/

[9] https://www.shenghai-alu.com/article/advantages-of-cnc-machining-for-aluminum-extrusion.49

[10] https://www.alexandriaindustries.com/content-library/demand-innovation/aluminum-extrusion-increases-options-optimize-supply-chain/

[11] https://www.zetwerk.com/resources/knowledge-base/aluminum-extrusions/aluminum-extrusion-machining-products/

[12] https://www.centralsteeltr.com/home/resource/the-gauge/5-questions-on-aluminum-extrusions