Content Menu

● Understanding PE Tube Extrusion Equipment

● Key Factors to Evaluate High-Quality PE Tube Extrusion Equipment

>> 1. Production Capacity and Output Requirements

>> 2. Technical Specifications and Features

>> 3. Equipment Reliability and Durability

>> 4. Price and Cost Considerations

>> 5. Supplier Reputation and After-Sales Support

● Evaluating Production Quality and Troubleshooting

● Advantages of High-Quality PE Tube Extrusion Equipment

● Conclusion

● FAQ

>> 1. What factors influence the high quality PE tube extrusion equipment price?

>> 2. How important is automation in PE tube extrusion equipment?

>> 3. What maintenance practices ensure long-term performance of PE extrusion equipment?

>> 4. How does screw design affect PE tube extrusion quality?

>> 5. What should be considered when choosing a supplier for PE tube extrusion equipment?

● Citations:

Polyethylene (PE) tube extrusion equipment plays a crucial role in producing high-quality PE pipes used extensively in construction, agriculture, water supply, and other industries. Investing in high-quality PE tube extrusion equipment is essential for manufacturers aiming to achieve consistent product quality, operational efficiency, and cost-effectiveness. This comprehensive article explores how to evaluate the value of high-quality PE tube extrusion equipment, focusing on technical features, production capacity, cost considerations, supplier evaluation, and maintenance factors. It also highlights the importance of the high quality PE tube extrusion equipment price in balancing investment and returns.

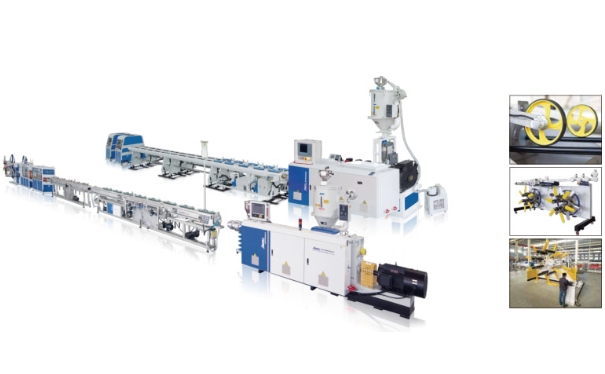

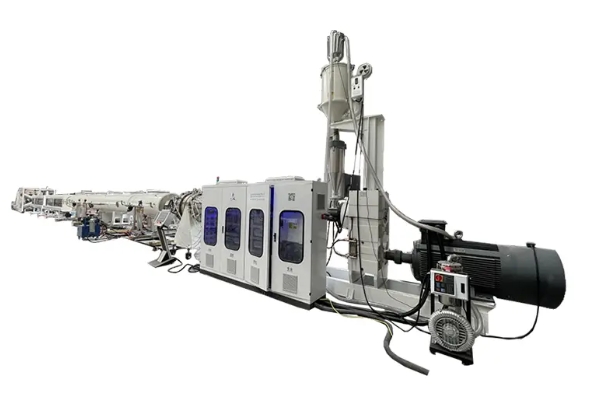

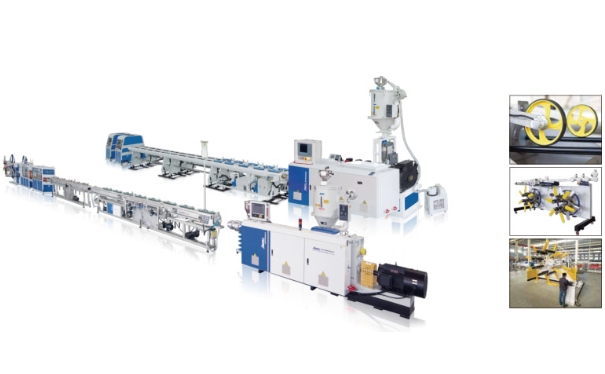

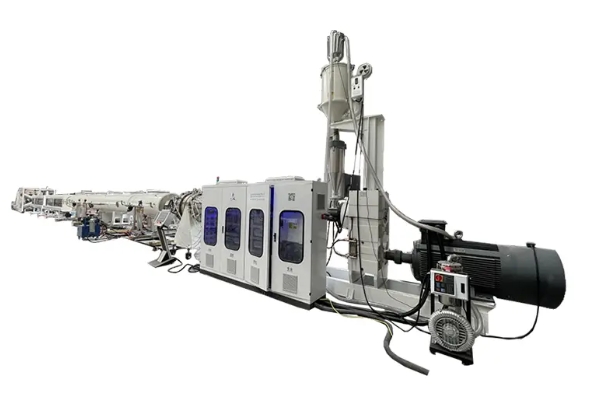

Understanding PE Tube Extrusion Equipment

PE tube extrusion equipment transforms raw polyethylene resin into continuous tubes or pipes through a controlled melting and shaping process. The equipment typically includes several key components:

- Extruder: Melts and homogenizes the polyethylene material.

- Screw and Barrel: Mix and convey molten material.

- Die Head: Shapes the molten plastic into tubes.

- Cooling System: Solidifies the tube while maintaining shape.

- Haul-Off Unit: Pulls the tube at a controlled speed.

- Cutting or Winding Unit: Cuts tubes to length or coils them for storage.

High-quality equipment ensures precision in each stage, producing tubes with uniform dimensions, smooth surfaces, and consistent wall thicknesses[10].

Key Factors to Evaluate High-Quality PE Tube Extrusion Equipment

1. Production Capacity and Output Requirements

The first step in evaluating extrusion equipment is matching production capacity with your manufacturing needs. Consider:

- Output volume: How many kilograms or meters of PE tubes are required per hour or day?

- Tube diameter and wall thickness range: Equipment must support your target product specifications.

- Production speed: Higher speeds increase output but require precise control to maintain quality.

Selecting equipment with a capacity about 20% higher than your maximum production needs helps avoid running machines at full load continuously, improving longevity and reliability[1][7].

2. Technical Specifications and Features

High-quality PE tube extrusion equipment should have advanced technical features that ensure product consistency and operational efficiency:

- Extruder Screw Design: Efficient screw geometry (length-to-diameter ratio, pitch) ensures uniform melting and mixing of PE resin, affecting tube quality and throughput[1].

- Temperature Control: Precise barrel and die temperature management prevent defects such as uneven wall thickness or surface roughness[1][4].

- Die Head Engineering: A well-designed die head ensures dimensional accuracy and smooth tube surfaces, minimizing material waste[1][4].

- Cooling System Efficiency: Proper cooling tanks and water circulation maintain tube shape and mechanical strength during solidification[1][4].

- Automation and Control Systems: PLC-based control with real-time monitoring optimizes extrusion parameters, reduces operator error, and improves productivity[2][9].

- Energy Efficiency: High-performance servo motors and energy-saving designs reduce operational costs while maintaining output[2].

3. Equipment Reliability and Durability

Long-term reliability is a hallmark of high-quality equipment:

- Use of corrosion-resistant materials and high-grade components reduces maintenance frequency and downtime[2].

- Robust construction withstands continuous production demands.

- Availability of spare parts and ease of maintenance contribute to sustained performance[1][8].

4. Price and Cost Considerations

The high quality PE tube extrusion equipment price varies widely based on capacity, automation, and features:

- Single screw PE pipe extruders range from approximately $20,000 to $58,000.

- Complete HDPE pipe extrusion lines can cost between $30,000 and $100,000 or more, depending on production capacity and automation level[3].

When evaluating price, consider:

- Total cost of ownership including energy consumption, maintenance, and downtime.

- Potential cost savings from energy efficiency and reduced material waste.

- Balance between upfront investment and long-term operational benefits.

High-quality equipment may have a higher initial price but often delivers better ROI through improved product quality and lower operational costs[2][3].

5. Supplier Reputation and After-Sales Support

Choosing the right supplier is critical:

- Verify certifications such as ISO 9001 and CE to ensure quality manufacturing standards[2][9].

- Assess supplier experience, technical expertise, and customization capabilities.

- Evaluate after-sales service, including technical support, spare parts availability, warranty terms, and training[1][9].

- Reliable suppliers contribute to smooth commissioning, minimal downtime, and faster troubleshooting.

Evaluating Production Quality and Troubleshooting

Even with high-quality equipment, monitoring production quality is essential:

- Check for surface defects like roughness or jitter rings inside tubes.

- Ensure uniform wall thickness and roundness within tolerance.

- Adjust process parameters such as temperature, vacuum degree, and cooling water temperature to resolve common extrusion issues[5][6].

Regular inspection and maintenance of components like the extruder screw, barrel, die head, and cooling system are vital to maintain consistent output quality[8].

Advantages of High-Quality PE Tube Extrusion Equipment

- Consistent Product Quality: Uniform dimensions, smooth surfaces, and mechanical strength meet industry standards[2].

- Energy Efficiency: Servo motors and optimized systems reduce electricity consumption and operational costs[2].

- Flexibility: Ability to produce various pipe diameters and wall thicknesses for diverse applications[2].

- Automation: PLC control systems reduce labor costs and human error, enhancing productivity[2].

- Durability: Corrosion-resistant materials and robust design ensure long equipment life and lower maintenance[2].

- Low Material Waste: Precise control minimizes scrap, reducing raw material costs and environmental impact[2].

- Compliance: Equipment certified to international standards facilitates global market access[2].

Conclusion

Evaluating the value of high-quality PE tube extrusion equipment requires a comprehensive approach that balances technical capabilities, production needs, price, and supplier reliability. The high quality PE tube extrusion equipment price should be viewed in the context of total cost of ownership and long-term benefits such as energy savings, product consistency, and reduced downtime. Advanced features like precise temperature control, efficient screw design, automation, and durable construction are essential for achieving optimal production efficiency and product quality. Selecting reputable suppliers with strong after-sales support further enhances the value of your investment. Ultimately, high-quality extrusion equipment is a critical asset for manufacturers seeking to maintain competitiveness and meet the growing demand for reliable PE pipes.

FAQ

1. What factors influence the high quality PE tube extrusion equipment price?

The price depends on production capacity, automation level, tube diameter range, screw design, energy efficiency features, and supplier reputation. Higher capacity and automation typically increase cost, but also improve efficiency and product quality[3][2].

2. How important is automation in PE tube extrusion equipment?

Automation enhances process control, reduces human error, improves production consistency, and lowers labor costs. PLC-controlled systems enable real-time monitoring and adjustments, increasing overall efficiency[2][9].

3. What maintenance practices ensure long-term performance of PE extrusion equipment?

Regular inspection and cleaning of screws, barrels, dies, and cooling systems; alignment checks; lubrication; and timely replacement of worn parts are essential. Monitoring operational parameters helps detect issues early[8].

4. How does screw design affect PE tube extrusion quality?

Screw geometry influences melting uniformity, mixing, and throughput. Proper design prevents material degradation and ensures consistent tube dimensions and mechanical properties[1].

5. What should be considered when choosing a supplier for PE tube extrusion equipment?

Look for certifications (ISO, CE), technical expertise, product range, customization options, after-sales support, warranty, spare parts availability, and delivery timelines. A reputable supplier ensures reliable equipment and service[1][9].

Citations:

[1] https://machine.goldsupplier.com/blog/hdpe-pipe-extrusion-machine/

[2] https://jiantaimachine.com/plastic-extruder/pe-pipe-extrusion-equipment/

[3] https://www.yjing-extrusion.com/how-much-does-pe-tube-extrusion-equipment-cost.html

[4] https://machine.goldsupplier.com/blog/hdpe-pipe-extrusion-process/

[5] https://www.jwellextrusions.com/common-problems-and-solutions-of-pe-pipe-extrusion-line.html

[6] https://www.fangliextru.com/news-show-458688.html

[7] https://www.linkedin.com/pulse/what-keep-mind-when-buying-plastic-pipe-extrusion-line-nadir-emin-08urc

[8] https://www.polestar-machinery.com/news/essential-maintenance-tips-for-pe-extrusion-lines/

[9] https://www.jwellextrusions.com/selecting-the-right-hdpe-pipe-extrusion-line.html

[10] https://www.caisumachinery.com/what-is-a-pipe-extrusion-machine-a-complete-guide/

[11] https://www.jwellextrusions.com/selecting-the-right-pipe-extruder.html

[12] https://www.hmel.in/assets/pdf/technical_guide_to_pipe_extrusion_process_&_polysure_products-final_small.pdf

[13] https://www.twinscrew.net/en/article/Medical-Tube-Extrusion-101.html

[14] https://drts.com/what-to-look-for-extruder-machine/

[15] https://www.fangliextru.com/news-show-1048140.html

[16] https://www.linkedin.com/pulse/analyzing-plastic-extruder-machine-price-beyond-purchase-andrea-chan-haqge

[17] https://www.qenos.com/internet/home.nsf/(LUImages)/TG7Pipe/$File/TG7Pipe.pdf

[18] https://www.caisumachinery.com/what-is-a-pipe-extrusion-machine-a-complete-guide/

[19] https://www.futuremarketinsights.com/reports/extrusion-equipment-market

[20] https://machine.goldsupplier.com/blog/hdpe-pipe-extrusion-process/

[21] https://www.blessonextrusion.com/pe-pipe-extrusion-machine/

[22] https://trustymachine.en.made-in-china.com/product/ITFpuCkcnbVY/China-High-Speed-High-Quality-Best-Price-PE-PPR-Pipe-Extrusion-Machinery-Line.html

[23] https://www.fangliextru.com/news-show-566486.html

[24] https://qsplasticmachine.en.made-in-china.com/product/yOPfjFxUnLTb/China-High-Quality-200-400-HDPE-Plastic-Water-Pipe-Extrusion-Equipment.html

[25] https://www.dynisco.com/userfiles/files/27429_Legacy_Txt.pdf

[26] https://www.pe100plus.com/PPCA/Key-Parameter-for-Improving-Extrusion-Productivity-p939.html

[27] https://qsplasticmachine.en.made-in-china.com/product-group/foFTiLzdnPWq/PE-Pipe-Extrusion-Line-1.html

[28] https://www.alibaba.com/product-detail/High-quality-PE-tube-extrusion-machine_1601203398363.html

[29] https://saextruder.en.made-in-china.com/product/SaPRegfhCqkw/China-High-Pressure-Pipe-Extrusion-Machine-PE-.html

[30] https://www.friendplasticmachine.com/quality-10166874-250mm-pe-pvc-hdpe-plastic-pipe-extrusion-machine-100-250kg-h-capacity

[31] https://www.alibaba.com/showroom/cosmetic-tube-extrusion-machine.html

[32] https://www.yjing-extrusion.com/what-s-the-best-price-for-pe-tube-extrusion-equipment.html

[33] https://www.alibaba.com/showroom/polyethylene-extrusion-machine.html

[34] https://polysen.en.made-in-china.com/product/JmQpRMDCJSUF/China-High-Quality-HDPE-PE-PP-Plastic-Single-Screw-Extruder-Production-Extrusion-Line.html

[35] https://www.aliexpress.com/w/wholesale-pe-extruder-machine.html

[36] https://www.made-in-china.com/products-search/hot-china-products/Extrusion_Machine_Price.html

[37] https://www.friendplasticmachine.com/sale-10166874-250mm-pe-pvc-hdpe-plastic-pipe-extrusion-machine-100-250kg-h-capacity.html